Copper annealed pipe: what is it?

The use of copper pipes dates back to the last century and remains popular to this day. The main reason is that copper is considered practically the most resistant material that is used for the construction of many engineering systems. The characteristics and technologies of pipe production are constantly being improved, in particular, copper annealed versions, which have unique properties.

Features and differences

Today the market offers two types of copper pipes: annealed and unannealed. They differ in production technology and some properties. At the initial stage of the production of pipes, special ore processing takes place, as, incidentally, when working with other various metals. After this, oxygen is purged in order to exclude the presence of various impurities.

Unannealed pipes are heat-treated to obtain an annealed version, using heat (annealing) to + 600–700 degrees Celsius.

After these procedures, a process of gradual cooling or tempering occurs. Due to this, the strength and flexibility of the sample increases significantly. At the outlet, the tube acquires completely different characteristics. This is the main difference between the annealed and unannealed. For example, the annealed version with any mechanical stresses before rupture is deformed, namely stretched, which means that this product is characterized by a high degree of flexibility and elasticity.

If we consider in more detail the differences in the properties of these two types, then the following should be noted:

- annealed pipes withstand up to 5 freezing cycles, while only expanding slightly;

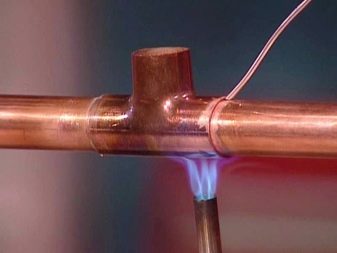

- due to the plasticity they are easy to connect with each other fittings, such a connection will be no less tight than welding.

Advantages and disadvantages

Based on the above, it becomes clear that the annealing procedure allows the copper tube to acquire a number of additional useful qualities, therefore Annealed copper pipes have many advantages, among which the following should be noted:

- they can withstand virtually any pressure, especially thick-walled models;

- almost immune from sudden changes in temperature and pressure, humidity and ultraviolet. For example, the maximum temperature is usually about +250 degrees, and the minimum is about -100 degrees;

- in connection with flexibility, pipes can bend, and also there are various forms;

- Installation is characterized by simplicity, they contain a small amount of parts, which does not complicate the design. The resulting system is characterized by reliability. To increase the strength of the joints between the pipes used brass insert (sleeve);

- long service life, which is several decades, manufacturers guarantee a century of operation and more;

- the bactericidal properties of copper make it possible to safely use such pipes for water pipes in homes;

- high resistance to corrosion process.

Important: the unannealed pipe does not possess most of these properties.

Despite the large number of advantages, these pipes have the same disadvantages as all the products.Although they can be called features rather than disadvantages.

It is worth noting the following.

- The cost of copper pipes is quite high relative to analogues from other materials. But it, of course, pays off a long operational period.

- There may be some installation difficulties, mainly when fittings or soldering are used.

- High thermal conductivity, in connection with which the pipes may heat up, and there is a risk of burns. Currently, manufacturers cope with this as follows: the products are covered with various polymers, thereby creating thermal insulation, thereby reducing thermal conductivity, and the pipes are becoming safe for humans.

Spheres of application

Due to the fact that copper pipes are not particularly durable, but flexible, the main scope of their application is the arrangement of household systems, as a rule, plumbing. They are equally suitable for both internal and external systems, due to their excellent resistance to UV rays.

The range of use of such pipes is quite wide:

- in air conditioning systems, due to the fact that copper does not react with cooling fluids;

- in systems of heating and water supply, both hot and cold;

- in a variety of hydraulic devices.

Copper pipes in the annealed form are chosen for such engineering systems due to their trouble-free, relative ease of installation and long-term use. But the main criterion for the durability of the product remains its quality and compliance with all rules in the production.

Dimensions

The two main parameters of copper pipes are the outer and inner diameters. Proper selection of the size of the product is the key to its long service life. For different systems it is necessary to select the optimum diameter. For example, for water supply systems, pipes with parameters of 8–22 mm and a thickness of no more than 1 mm are chosen. For a heating system, it is necessary to calculate the diameter according to certain parameters. For laying the gas pipeline using copper pipes with a diameter of not more than 15 mm and a thickness of 5 mm.

Since products are manufactured according to GOST, some of their parameters can be specified in inches.

For convenient and fast translation it is recommended to use the following table:

| Pipe size in inches | Outer diameter in mm | Wall thickness in mm |

| 1/4 | 6 | 0,61 |

| 3/8 | 10 | 0,71 |

| 1/2 | 12 | 0,89 |

| 3/4 | 18 | 1 |

| 1 | 28 | 1 |

| 3 | 76 | 2 |

4 1\8 | 108 | 2,79 |

When translating you need to be careful, despite the fact that the procedure is not very complicated. As a rule, the parameters of the product are indicated as follows: 42 mm x 1, where the first number is the outer diameter, and the second is the wall thickness.

It should be noted that the optimum diameter of this product is directly related to the nominal pressure in the pipeline.

Selection

Annealed copper pipes are a fairly universal option and are suitable for many systems, therefore, specialized construction stores contain a large selection of these products. As a rule, the assortment is wider than that of unannealed ones. When buying and choosing this part, you need to pay special attention to the absence of any defects on the surface. The cross section of the pipe should be typical.

In this regard, it is necessary to remember the following basic criteria in order to choose a quality product:

- pipe size - it should be determined in advance;

- a method of manufacturing the product - with or without roasting;

- appearance and quality.

These and other data are contained in the label, which is applied to the pipe in full compliance with GOST.

You can find out more information about copper pipes in the following video.