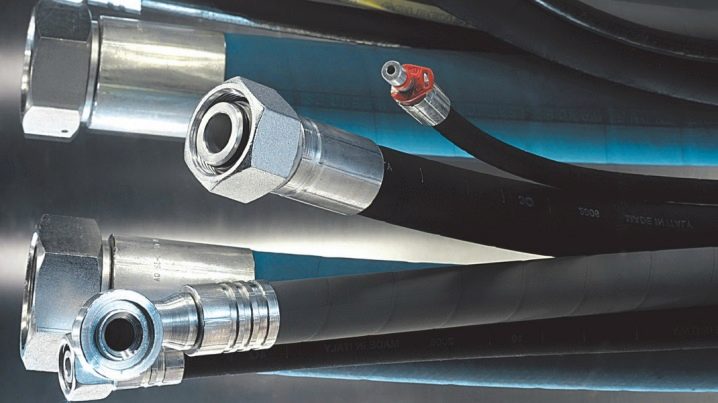

Fittings for high pressure hoses: types and purpose

When organizing a comfortable life in the house, an important point is the connection of pipe fittings and high-pressure hoses. Such devices are called fittings, with their purchase special attention is paid to standards and GOST standards on connectors for high-pressure hoses.

What it is?

Connecting fittings for high-pressure hoses are the elements that make up the nuts and fittings. Thanks to them, high-pressure hoses are connected to the hydraulic circuit, and regulation of the transporting fluids in the hydraulic circuits. Connecting parts differ in the shape, size and threaded connection. The pricing policy of such devices can reach up to 40% of the cost of the entire hydraulic circuit.

In hydraulic pipes there are elements subject to harmful factors:

- changes in temperature conditions;

- overpressure;

- vibration;

- aggressive environment;

- mechanical abrasion.

The most commonly used design of fittings is the body, nut or fitting.

In addition, the device threaded connections are available:

- sealing and insulating rings;

- crimp sleeve.

The case of devices is made most often from brass, less often from polymer raw materials, the fittings of which are installed on sewer pipes. The use of these materials allows you to provide the necessary parameters for fittings. Insulation rings are made of Teflon, and are designed for galvanic isolation between the two parts of the hydraulics system, which helps to prevent corrosion damage. Crimping sleeve is made of alloy steel.

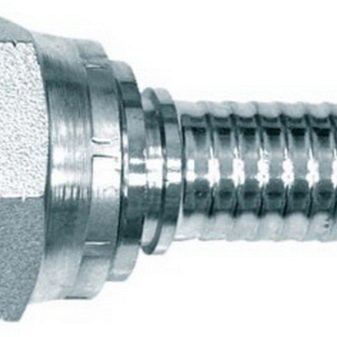

The part of the fitting required to crimp the sleeve is called the “tail”. It is manufactured by high technology, thanks to which the system is crimped. Attaching the "tail" to the pipe is provided by the connecting part, which is called the "head". It also plays the role of a sealing joint using a bolt, gasket, conical thread, spherical plane, sealing ring or cone.

Fittings are made using metric, cylindrical or tapered threads.

Threaded connectors for high-pressure hoses make it possible to quickly and reliably assemble pipelines of any sections and constructive forms. When installing the connecting elements it is recommended to use fum-tapes in order to avoid possible leaks. If you comply with all the requirements of the instructions during the installation of devices, you can ensure long and reliable operation.

Requirements and standards

To ensure reliable and efficient operation of connectors for high-pressure hoses, even under harsh conditions of use, the technical features of the devices must comply with strict technical regulations. Properly organized hydraulics must pass a leak test in the connection areas. Fittings must be sturdy, reliable, explosion proof, durable, and have an optimal cost. They should also be manufactured using innovative technologies that are resistant to corrosion destruction and also function in the conditions of transportation of corrosive liquids.

There is a wide range of RVD fittings on the building materials market; however, no model can meet all GOST standards at the same time.Therefore, when purchasing these devices, you first need to check their serviceability, which will guarantee trouble-free service of hydraulic systems. The quality and service life of the WFD depends on the design features and applied technologies.

Since leakage of oil environments from hydraulic systems leads to breakage of plumbing devices, this means that the material used to manufacture fittings for high-pressure hoses must be high-strength, wear-resistant, durable, and withstand constant temperature stresses.

When installing fittings on metal pipelines, they are made of cast iron, steel, copper or brass. Connectors for plastic pipelines are made from polypropylene raw materials.

In accordance with specifications and standards, fittings for high pressure hoses should:

- to function with an excess pressure up to 20 bar;

- work stably at wide temperature ranges 55-120 degrees Celsius;

- Do not be afraid of concentrated acids and other corrosive liquids;

- be resistant to mechanical abrasion.

Kinds

Only the following types of devices meet the technical conditions and GOST.

- DK and DKI, mounted on hoses with a cross section of up to 3.2 cm in the presence of thread. Fittings are manufactured by Russian manufacturers.

- DKO and JIS - connectors with a thread up to 5 cm, are mounted on hoses with a section up to 5 cm. They are produced in Japan and in the countries of Europe.

- JIC and BSP - connectors, are intended for installation in loops with pipe threads. Produced by American and British manufacturers.

- ORFS - devices equipped with threaded unions and nuts. They are mounted on hoses with a diameter of not more than 5 cm and are made exclusively in America.

- NPTF - connectors with tapered threads.

- SF - plug-in connecting devices installed on sealing elements.

- BANJO - unique details with transverse boring of the butt. Installed in order to avoid arranging additional taps.

When assembling elements of hydraulics, depending on the area of branching, the following types of connecting elements for high-pressure hoses are distinguished.

- Squares - necessary for redirecting the WFD at a right angle or 45 degrees.

- Tees - designed for the construction of branches from the main pipeline.

- Crosses - designed to create pivot branches from the main pipeline.

- Couplings are devices necessary for connecting two parts of pipelines with the same section.Often they are used to fasten the high-pressure hoses to the tank or pumping unit. Couplings are made of various materials, but bronze and brass specimens are particularly popular.

- Plugs are devices designed to temporarily seal the edges of the high-pressure hoses.

- Fittings - elements for connecting pipes with different sections. At their two ends there is an internal and external threaded connection. The fittings are used for pumping liquid and gaseous media in several directions.

Rotary choke connectors that transport fluid to rotating parts of a circuit are especially popular.

There are special requirements for such devices, their installation and maintenance.

- Nuts - the simplest adapters with a hole and thread from the inside. Designed for reliable attachment of the RVD to the connector.

- Nipples are devices that look like a metal pipe with a thread. Designed to connect one sleeve to another for any duration. Reliability of fastening in many situations is reached thanks to connecting elements. In some cases, a small non-return valve is located inside the nipple to preventreverse fluid flow through the pipes.

There are also nipples for connecting hoses. In such situations, at the ends of the elements there is a thread designed to tie together the ends to be joined. In many cases, for connecting parts of pipes, shut-off devices are used - rotary valves, thanks to which it is possible to shut off the flow of the circulating flow.

Depending on the type of shank, the following types of connecting elements are distinguished.

- Multifit with universal shank is the most popular type. It is applied with many types of sleeves, an exception - the pipes having six navivok.

- Interlock - fittings used in sleeves with four or six hoops. They are resistant to hydraulic shocks and overall dimensions.

- SC series fittings are devices used in high-pressure hoses with a number of four or six windings without removing the inner and outer layers.

- Fittings of the 19th series are parts for the connection of hoses with large-section navivka. During operation, the outer layer of the sleeve is removed. These are reusable devices mounted on rubber hoses.

Depending on the connecting part, there are threaded and non-threaded connectors for high-pressure hoses.

It is necessary to elaborate on the varieties of the second type of connectors.

- Connector - used in the repair work during ruptures RVD. Externally, these are two connected identical shank.

- Banjo - ring connectors, mounted with special bolts with inch or pipe threads.

- Steck - lock type connectors. Tightness is achieved by sealing rings, and docking - by locking the locks.

- BEL and BES - smooth-shaped connectors, the installation process is carried out using sealing elements and nuts.

- UTS - mounted by soldering. Externally, it is a cylindrical device, inside which the welded elements.

- Flanges - connectors to create kinks at a right angle or at a 45 degree angle. Tightness is achieved by sealing rings.

Threaded connectors are classified by type of threaded connection:

- metric - standards for European standards (DIN / GOST);

- pipe - English norms (BSP);

- inch - US standards (SAE)

Scope of application

Threaded connectors for high-pressure hoses are used in the industrial segment and in everyday life.

- For the circulation of petrochemical agents, food additives and water for drinking purposes.Such devices are mounted on pressure-suction hoses, made from chemically inactive raw materials, that is, they do not interact with the circulating fluid. High pressure hoses are operated at temperature differences from - 50 to +90 degrees, and with an overpressure of 0.8-10 bar.

- For the circulation of non-aggressive environment, automotive and jet fuels, compressed gases and superheated water vapor. The system operates at a maximum pressure of 10 bar and a temperature of up to 175 degrees. Fittings are installed on pressure hoses, which are reinforced in several layers of the frame.

- For pumping gasoline and other fuel fractions. The system operates at a maximum pressure of 5 bar and a temperature not exceeding 120 degrees. Fittings are mounted on the hoses of fuel-dispensing installations, which provide protection against static electricity.

- For the circulation of combustible gases and liquids from the tanks to the cutter. Fittings are installed on reusable gas-welding hoses, which are considered the most durable and operate at a maximum pressure of 20 bar and a temperature of up to 70 degrees.

- For transfer of hot and cold air masses, as well as hot water.Fittings are mounted on pneumatic hoses that can withstand an overpressure of up to 5 bar.

How to choose a fitting for RVD, see the following video.