Copper pipes: types of products and the process of their installation

In recent years, copper pipes made using seamless technology have become increasingly in demand among owners of private houses. It is the manufacturing method in combination with the unique properties of the material itself that caused such a wide popularity of these products.

Special features

To begin with we will focus on the technical characteristics of the pipes:

- breaking pressure - 220-290 kg / sq. cm;

- critical temperature - 400 degrees Celsius;

- frost resistance - 5 cycles of freezing and thawing.

Basic technical parameters of copper pipes are prescribed in GOST 617, which was last edited in 2006, with various versions of this document being updated every 10 years since the 1920s. last century.According to the latest standard, copper pipes are made either from pure copper or from brass - copper-zinc alloy, which is why all the basic characteristics, first of all, depend on the parameters of these structural materials.

By the way, seven grades of copper are taken for the production of pure copper pipes: from 99.5% M3 to 99.9% M1, and only one L96 grade, which contains 95% copper and six more components, the main of which is copper, is used for brass.

The service life of copper pipes reaches 60-70 years. These are extremely reliable products. If you compare them with steel analogs of the same size, you can see that the latter operate at a pressure not exceeding 100 bar, and the working temperature of the coolant should not exceed 250 degrees. Copper pipes effectively transfer liquids at pressures up to 500 bar, and the temperature of the transported liquid sometimes reaches up to 600 degrees.

Unlike many materials that are used to manufacture pipes, copper does not break when the temperature drops sharply. Moreover, it even increases its plasticity and strength. Copper pipes can repeatedly carry freezing and subsequent thawing without prejudice to their physico-technical characteristics.If an emergency situation arises on the copper pipeline, it is localized in a small area - this is the great advantage of copper pipes over all others, in which a breakthrough quickly spreads throughout the pipe. This determines the cost-effectiveness and practicality of maintenance of copper and brass pipelines, since repair work is much cheaper than replacing pipes in the event of a breakdown of steel lines.

Smoothly cut pipes are offered for implementation, the maximum allowable taper should not exceed 2-7 mm for pipes of different diameters. There should be no cracks and visible tears in the places of the bends, this also applies to the forced stretching of the product.

Advantages and disadvantages

Under certain conditions, copper pipes can be operated for quite a long time: if the heating and plumbing systems are designed and installed correctly, then their service life is several decades.

Copper pipes have a number of advantages.

- Copper is a very plastic and durable material, due to this it is possible to manufacture pipes with thin walls, which generally reduces their weight and greatly facilitates transportation and installation.

- A distinctive feature of copper and its alloys is the ability to withstand high and low temperatures: from -40 to + 115 ° С. Such pipes are not afraid of even freezing, this quality is very much appreciated in regions with a harsh climate.

- In order for copper to tolerate an aqueous medium, phosphorus-containing components are added to its composition. As a rule, such products are marked EN1057 and can be used both for heating and for water supply, because they do not react with water.

- It is noteworthy that copper pipes do not require an exterior finish, they initially have an aesthetic appearance that remains consistently attractive over time. Although if the pipes do not match the style and interior design, then they can be painted in any selected color.

- Copper and brass do not allow any gaseous substances, including oxygen, which is known for its oxidizing properties.

- Copper pipes have a smooth internal surface, this is what makes it different from steel products, so the risk of lime deposits and, accordingly, a reduction in the working clearance is significantly reduced.

- The coefficient of thermal expansion of the metal is quite low and this is also a big plus.

- In small dosages, copper gets into a portable liquid, namely, into water.It is even useful because copper has soft antiseptic properties. A few years ago it was reported about the adverse effects of copper on the human body, but these facts have not been confirmed, today it is believed that copper is absolutely harmless, even in large doses.

The list of advantages of copper is quite serious, however, the disadvantages are no less significant.

- Copper is absolutely not combined with any other materials. For example, when aluminum elements are included in the system, active electrochemical interaction inevitably begins. When contacting with other metals, the structure of the material begins to break down quite quickly, while a large amount of gases is released at the time of the reaction, and if there are no gas discharge valves in the water supply system, it can simply be broken off from the inside.

- Both the pipes themselves and the components for them are quite expensive, and this is despite the fact that the installation of such pipes requires solder, which also costs quite a lot, even its rent can cost a lot of money. Moreover, it is impossible to install aluminum and cast-iron radiators with copper pipes, only copper ones can be suitable here, therefore the copper pipeline is rather expensive.

- Copper, as already mentioned, is a soft and very plastic material, so it is quickly erased if the transported liquid contains solid particles. Experts recommend installing a special filter that will trap all abrasive particles from an aqueous medium.

- Everyone knows that copper conducts electricity perfectly, so the system must be isolated from stray currents — install grounding and dielectric pads in the water mains.

- It is very important to protect the pipes from mechanical damage, otherwise in a few years you risk not getting pipes, but a shapeless pile of metal.

Copper has several properties that, depending on the conditions of use, can be attributed to both advantages and disadvantages.

- High thermal conductivity. If the copper pipeline is open, then these pipes emit a lot of heat and radiators require much less - this is a plus. But if the system is closed, then all the heat from the pipes can give to the walls, especially if these are the ends of the buildings facing the street - this is a minus.

- Softness. Pipes can bend in different directions, which means that for the installation of water supply less fittings and other connections are required - this is an absolute advantage.However, the material is so soft that it needs to be additionally fixed at fairly small intervals, since when moving warm media they can deform - this is already a drawback.

In addition, when mechanical damage such pipes are very easily deformed, and this reduces the circulation of fluid. Therefore, all repairs and rearrangement of furniture in the room should be done very carefully so as not to damage the pipes.

However, in fairness it should be noted that in the overwhelming majority of cases all the problems that may arise in connection with the use of such pipelines are due to the poor quality of the products, since a properly built system always works efficiently. But if at least one piece was made of poor-quality material, problems may arise. For example, if the water supply system is assembled from copper purchased from a reliable supplier, and one piece is purchased on a dubious tray on the market, then within a year or two a blue film will appear on the plumbing equipment, followed by active corrosion and rust.

Kinds

In everyday life, as a rule, use two types of copper pipes:

- annealed;

- unannealed.

Annealed pipes in the production process are subjected to thermal firingAs a result, the products acquire a special softness, this greatly facilitates the installation of pipes, however, at the same time, their strength characteristics deteriorate. Accordingly, unannealed versions are more reliable, but less plastic. Annealed pipes are realized in 2–50 meter lengths twisted into coils. Unopened go on sale in the form of straight segments, usually 5-meter.

The shape can be distinguished standard round and special pipes with a rectangular cross-section. Most often they are used to make the conductors of electric machine windings, which are cooled using the liquid method. The length of the sides of such pipes varies from 1.2 to 290 mm, and the wall thickness varies from 0.8 to 3 mm. Such a pipe is sold in lengths of 1-6 meters, as well as coils, if the diameter is small.

It is exactly rectangular unannealed pipes that are most often used in split systems., they are exactly cut off and do not have burrs, can withstand high pressure. It should also dwell on such varieties of copper pipes as ribbed.Such products are presented in two versions - mono - and bimetallic. The first are made by casting method, that is, the compound of the source material and the fins is missing. The result is a fairly reliable heat exchanger, characterized by a long service life.

Production of bimetallic pipes occurs in one of three ways:

- knurling - when an aluminum tape is pressed onto a copper pipe, which, in turn, is pressed into ribs by rolling;

- pouring - at the same time the grooves are rolled, and only after that the aluminum tape with a section in the shape of the letter L is put on;

- in the third embodiment, the pipe and steel tape are heated using high-frequency current, at which time the tape is welded to the pipe, such models are used in heating boilers.

Depending on the implementation variant, the metric pipe is different in sections and in coils. The thickness of the wall stands out thin-walled and thick-walled tube.

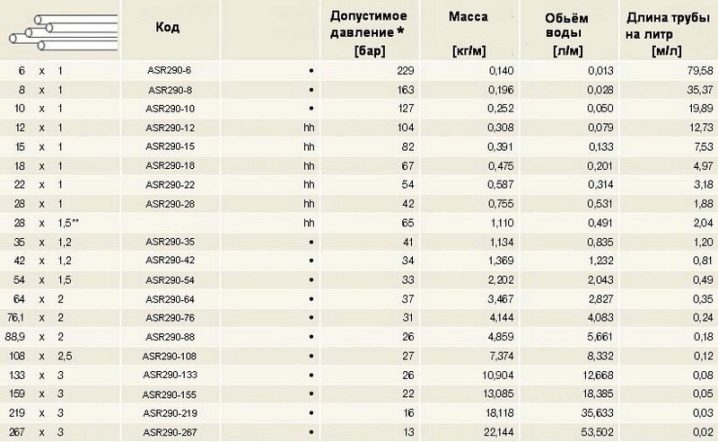

Dimensions

As a rule, the section of the pipe is conventionally denoted in English inches, however, it seems difficult only at first glance.Having understood, we can literally translate these values into “on-the-fly”, although to facilitate calculations there is a special table that can be found in any open source.

Pipes of different sizes have different uses.

- Thus, pipes of 10 mm and less are used for arranging internal heat exchangers in heating systems. Due to the small size, the highest efficiency of such devices is achieved due to the high degree of energy transfer.

- Pipes with a diameter of 10-25 mm are used for the construction of water pipes.

- But for drainage systems and sewage systems, pipes with a size of 40-45 mm should be preferred, these models have good maneuverability, even despite the relatively small size.

Scope of application

Copper pipes have a fairly wide scope of use, most often they are installed in:

- heating pipelines;

- hot and cold water systems;

- highways that move compressed air or gas;

- freon supply units in refrigeration units;

- hydraulic oil supply systems;

- fuel installations;

- condensate extraction systems;

- when installing technological equipment;

- air conditioning systems, etc.

Separately, one should focus on the existing restrictions on the use of copper pipes, which are caused by the specific parameters of the material itself.

- As already mentioned, copper is ductile and soft metal, so the maximum permissible flow rate through pipes made of this metal is 2 meters per second, respectively, if the speed of the moving working medium is higher, other materials should be used.

- If solid particles are present in the water that moves through the water supply systems, over time this can lead to metal damage and shorten the life of the pipeline, so the use of copper pipes is possible only under conditions where the water passes through a coarse filter.

- The hardness of the water in contact with the pipes should be in the range of 1.42–3.42 mg / l, and the acidity should be 6–9. Only in this case an oxide film is formed on the inner surface of the pipes, which provides protection for the coating. If this requirement is not met,the patina on the surface will constantly collapse and recover, then collapse again - this leads to a decrease in wall thickness and their early wear.

- Lead-based solders cannot be used on copper pipes that provide drinking water.

- Taking into account the fact that the approximate period of use of copper pipelines is 50 years old, they should be installed in such a way that in no case is it shortened, namely: twisting and creasing of pipes are strictly not allowed, as well as the alignment of dents on them once. It is important to monitor the temperature of the working environment, since overheating leads to deformations and a significant reduction in the strength of the joints.

Tools for work

In working with copper pipes use special tools.

Pipe cutters

They are necessary in order to cut pipes of the required length. By the way, this tool is effective not only for working with copper pipes, it copes well with plastic, steel and metal-plastic. Truborez provides strict perpendicularity of the cut and the required quality of the end.The tool is optimal when you have to work with gaseous or other highly flammable materials, because there is no spark in such a tool that can cause a fire. It is very convenient that the pipe cutter works without the use of electric current, this makes it effective to use it in remote areas where there is no widespread electrification.

For copper pipes, two types of pipe cutters are used.

- Steel telescopic with a clamp-shaped body - on one side of this tool there is a cutting roller, and on the second - an axis carriage with several guides. At the moment of rotation of the handle, the carriage begins to move and thereby clamps the pipe. After the pipe cutter is turned completely around the helical axis, an incision is made, and if at this moment the pressure on the handle is increased, then the pipe section is cut off completely.

- With a ratchet mechanism - purely visually, such a pipe cutter is similar to scissors, with one part of them made in the form of a C-shaped notch, and the other side is cutting. To make an incision in the pipe, it is necessary to close the handle.

Pipe expander

Everyone knows that the pipeline is an extensive network, which consists of pipes of different sizes, which is why the use of a pipe expander is essential when installing the system - without it, it is impossible to connect individual elements using couplings or fittings. The product can be manual or electric, the first is optimal for small-scale works, and the second is for installing complex systems.

The pipe expander is used to make the connection using fittings as convenient as possible. It must be borne in mind that for individual versions of pipes of different diameters, a separate expander should be used, however, there is no need to acquire several pipe expanders, it is enough to create a supply of several heads of different sizes.

Pipe bender

As the name implies, pipe benders are used to bend pipes.

The tool can be mechanical or manual.

- Mechanical pipe bender made in the form of a hydraulic press. Such options are optimal when the work is done in large volumes, because they provide a more powerful force than manual models.The components of the pipe bender are a hydraulic cylinder, frame, pump, rollers for fastening the pipe, interchangeable nozzles of different sizes and control knobs. In order to reduce the possibility of overheating, a special relay is installed. This press is mounted on a solid base. Its weight depending on the working capacity can vary from 29 to 129 kg. The pipe bender is widely used both in the industry, and in life.

- But for small works and good manual tool, it allows you to bend the pipe 90 degrees. This option is optimal for working in cramped conditions, as well as at height.

Press tongs

This tool is made from steel and is used to clamp press fittings. The principle of operation here is simple: the contour clamps the fitting, and other zones form indentations. When buying this tool, it is very important to focus on the labeling, which serves as proof of compliance with existing quality systems. By the way, the product can have different profiles of crimping, however, this in no way affects the strength and reliability of fixation. In addition, to work with pipes of all types of copper will need a clamp, as well as a soldering iron and trimmer.

Installation

The installation of copper pipelines is carried out using special connections - fittings or using welding. Through press or collapsible pipe fittings are firmly joined to the elements of the heating system, however, welding works are most often used. When installing annealed copper pipes where necessary, they can bend so that the total number of joints and joints is reduced. To do this, use a pipe bender, through which you can get the necessary slope without compromising the overall patency of the system.

Keep in mind that the pipes do not bend by the hands, despite the fact that the material is soft and ductile, the use of its own physical strength leads to the fact that the pipes are bent, and with it the working clearance is reduced. That is why this method should not be used, even if the rolling is performed by a physically strong man.

Installation of crimp fittings does not require special equipment: The pipe is simply inserted into the groove to the full stop, and then tightly fastened with a nut, while the material itself should be pressed against the body of the fitting.In order to achieve maximum fit and complete sealing, it is necessary to use two keys. That's all the equipment you need. However, we should not forget about the specifics of crimping, which implies full control of tightness - such systems periodically begin to "drip", which is why the joints should not be bricked up, access to the pipes should be open.

Press fittings are installed using special press machines; this is a rather expensive installation option, however, the connection is strong and reliable, but one-piece. Experts note that capillary brazing is considered the most versatile way to install copper pipelines, this method allows connecting pipe segments of the same diameter to each other. To do this, flaring is done at one end, that is, its diameter is slightly increased, this allows you to insert one pipe into another.

The joint is cleaned with a special sponge or a metal brush, and then the connected surfaces are coated with flux. - This is a special composition that provides maximum adhesion of metal with solder.Pipes treated in this way are sequentially inserted into each other so that the gap between them does not exceed a fraction of a millimeter. Next, the solder is heated by a welded torch, and when the material reaches the melting point, all the cracks are filled with the molten composition.

After the seam is filled, it must be cooled, for this you can lower the joint in the water, or you can just leave it in the open air. In general, this process, like repair, is quite simple, however, it requires accuracy, thoroughness and compliance with safety regulations. Copper pipes are distinguished by an aesthetic appearance, but sometimes users paint such products so that the pipeline fits the overall concept of the interior.

It is very important that the paint used to do this meets the following conditions:

- the coating should not change color due to high temperature;

- paint should reliably protect from any types of external influences;

- even minimal flaking is unacceptable.

It is advisable to coat the pipes with a primer before applying the paint, experts recommend using a lead-meric compound.Keep in mind that the paint is not absorbed into copper, so you need to very carefully distribute it with a brush. And even in this case, a more or less even coating can be achieved only after 2-3 layers. However, you can use the paint from a can, it falls much more evenly.

In no case is it permissible to use copper paints to coat copper products: they darken under conditions of high temperature, as is the case in heating systems.

How to connect the copper pipes with their own hands, see the next video.