How to choose a self-regulating heating cable for pipes?

If you need the ability to protect the pipes from freezing, then you need to take care of the heating structure. The best solution to this problem is a self-regulating cable for the piping system. There are several types of heating cable available. In this article we will consider the features of the self-regulating mechanism, and also help determine the right choice for a different situation.

Special features

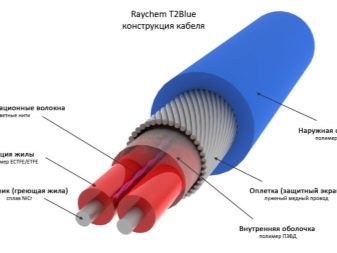

Externally, the self-regulating cable is similar to a similar heating device, only slightly flattened. This is due to the design of this mechanism. Thanks to this form, the product fits snugly to the heated material.

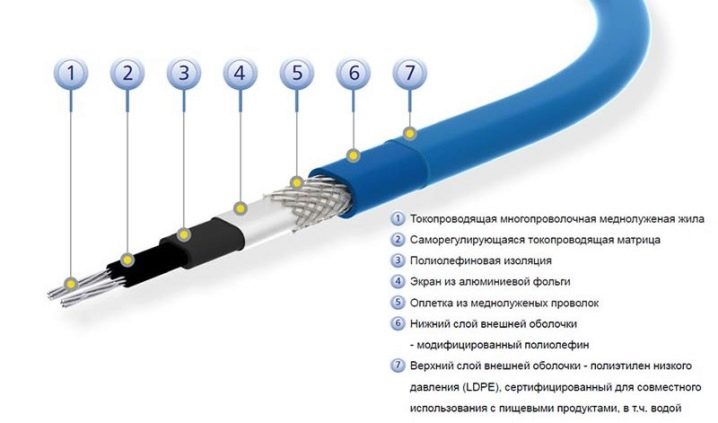

Heating cable special structure of the building. The gap between the two conductive wires installed matrix made of polymer building material. When the temperature in a particular area decreases, the conductive capacity rises, as does the heating.

If the area of the cable is warm, the product changes its properties, starts to keep the flow of electricity, as a result, the heating decreases.

The internal system of the product is equipped with protective shells. A metal screen is needed for grounding, and it also protects against mechanical damage. The outer shell of polyvinyl chloride increases the life of the material.

Mostly explosion-proof products are used to heat the piping system, various tanks. There are types of cables that are designed for arranging the heating system indoors, as well as outdoor installation in the soil or screed. In particular, it is necessary in case of severe frosts, so that there is no ice on the paths and sidewalks near the house. Many owners even use a heating element as an auxiliary heat source. For this purpose it is installed in furniture, mats, pillows.

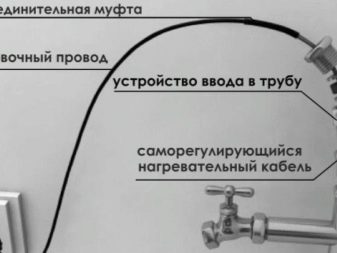

In industry, heating cables protect domestic piping systems, ventilation. To do this, the heating cable is connected to the power supply, which has evrovilka, through which the connection to the electrical network.

Self-regulating electrical wire has several advantages.

- In comparison with resistive cables, it is more simplified in operation. He is not afraid of overheating and does not require the same temperature conditions throughout the entire size of the product. This device is not afraid of sudden voltage drops. Unlike cable continuous heating self-regulating wire can be crossed. This is especially necessary when organizing heating of the construction of pipelines and their valves.

- Due to the peculiarities of the internal structure, the product can be cut into the required parameters. The smallest value is 10-15 centimeters. If you pay attention to the destination area of such devices, then in the near future they can displace resistive wires.

- The heating element is resistant to sudden temperature changes.

- Energy savings.

- Large range of productsYou can purchase a conductor of any size.

- Easy to maintain the device. Even an inexperienced owner can connect a self-heating element.

Despite the above advantages of the design, the mechanism has some negative sides:

- high cost of production;

- sold without components, they must be purchased separately.

Species

There are 2 types of heating cables available:

- resistive;

- self-regulating.

Resistive cable requires electrical connection at both ends of the product.It is for this reason that many owners choose self-regulating cable. Self-heating cable independently monitors changes in temperature fluctuations, controlling the level of heating. Heating electric cable for plumbing when the regime reaches 85 degrees suspends operation.

Cables differ in installation method: inside the structure or outside the pipeline. Both methods are quite popular, but in different conditions. If the diameter of the nozzle is small, the cable is installed on the outside of the pipe. Internal installation provides savings of electrical energy, because the fluid in the pipe is preheated, and then the structure itself.

The cable mounted inside the pipe is easy to replace if necessary. For a simplified replacement, you need to ensure the minimum number of angles, and the shortest possible distance.

This setup has negative sides.

- During mounting, there is a risk of damage to the heat cable on the sharp ends of the pipes. Damage check is not possible.

- In the future, at the point of cable exit from the plumbing system can leak.

- The cable around it collects various dirt and rust.

A conductor mounted over a pipe has several advantages.

- Easily fit on any pipe, there is a permissibility of heating the reinforcement (valve, filter).

- During the installation period, no physical effort is required, thereby reducing the risk of damage to the product.

- There is a low probability of damage, as there are no spikes on the outside of the pipe, unlike the inside of a pipeline.

- Easily carried out the dismantling of the structure.

- The conductor is not in contact with water, so the probability of the product getting under voltage is reduced by 0.

Subtleties of choice

In order to choose the right heating cable for pipes, it is necessary to pay attention to some nuances.

- The design of the heating cable may include 2 copper conductors, conductive current, a matrix, an insulating layer, a braid and a protective sheath. If the heat cable is not equipped with a braid, then this is an economical version of the system. Braid makes wiring durable, increases the resistance of the product to mechanical damage and grounded. Therefore, the best solution would be to choose such a variation.

- External insulation. For domestic use (heating of the roof and gutters, sewage), it is enough to purchase a heating wire with an insulating layer in the form of a polyolefin. If the cable heating system is planned to be used in production, it is better to opt for a cable with an insulating material in the form of a fluoropolymer. This material increases the resistance of the product to aggressive conditions and UV radiation. For the plumbing system, if the cable is mounted inside the structure, experts recommend to purchase a thermocable with an outer sheath of fluoroplastic.

- It is also necessary to pay attention to the temperature class of the product. The low-temperature heat cable is able to withstand a working temperature of 65 degrees, with a maximum heating power of 15 W / m. This type of manufacturing is better to choose to protect narrow pipes from freezing.The medium temperature conductor heats up to 120 degrees, the power can vary from 10 to 33 W / m. This type is recommended to use for drainage systems, pipes of medium size, heating the roof. The high-temperature conductor can heat up to 190 degrees with a specific power of 15–95 W / m. Such conductors are used in industry when heating of large-diameter pipelines is necessary.

The choice of the power of the heating conductor must be taken seriously, because inadequate power will lead to the fact that the heating system does not cope with its task, and high power factors will adversely affect the expenditure of electrical energy.

It’s quite difficult to talk about the limiting temperature of heating a self-controlled cable, because it depends on many factors:

- environmental conditions;

- parameters and materials of the pipeline system;

- thickness and thermal insulation characteristics;

- application areas of the heating element.

Pay attention to the manufacturer of these products. The most sought-after manufacturers with positive feedback from customers are Devi, Nelson, Lavita, Ensto.

Installation

Qualitatively carried out installation of the heating conductor can ensure long-term trouble-free operation of the plumbing and sewer construction.

First, let's get acquainted with how to install according to the instructions of the heating cable for the plumbing by internal and external methods, then we will talk about the nuances of connection and auxiliary thermal insulation of the structure.

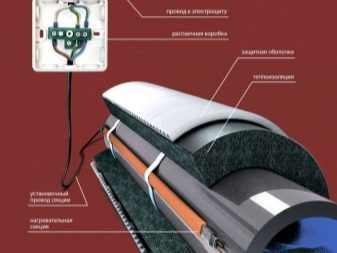

Outdoor cable installation

By pipeline

At the stage of laying the perimeter of the water supply, the installation of a heating conductor through a pipe is considered the best option. This can be done using two methods: along and around the pipeline system.

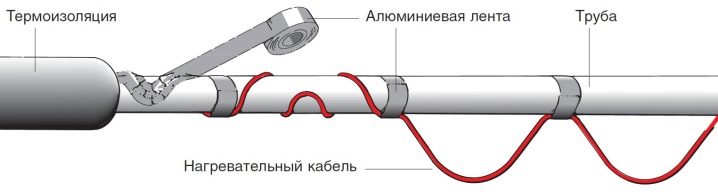

Along the pipe

In this situation, the mandatory rule is to mount the conductor under the pipeline, which allows you to protect the heating product from mechanical impacts from above. Since the water freezes at the bottom of the pipe, such an installation will make it possible to eliminate the freezing of the pipe in the shortest possible time. As a fixing material to the plumbing system used aluminum tape, which firmly fixes the conductor and increases its thermal performance. You can replace the tape with duct tape.

Special care must be taken when mounting the heating element in the corner areas. In order to make the bend not too large, it is advisable to install the cable over the outer radius of the nozzle.

Spiral

In areas with lower temperature conditions, it is recommended to install the heating conductor in such a way that it wraps the entire plumbing structure. In this case, the effectiveness of heating will be the highest, since the coil pitch is about 5 centimeters. When wrapping in a spiral manner, the electric cable should be 1.7 times larger than the pipeline.

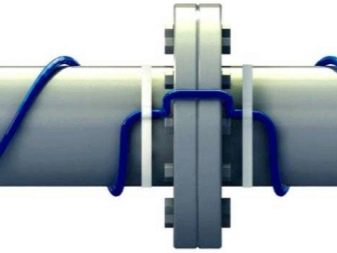

Individual nodes

Separate nodes are taps, valves and metal supports. At such sites, a greater amount of heating element is required, because there is a large diversion of thermal energy.

Special attention will be required when installing a temperature sensor. In order for the heating of the plumbing system to function properly and the conductor not to overheat, experts recommend positioning the thermal sensor on the coldest part. The installation area of the temperature sensor must first be glued with a strip of aluminum tape.

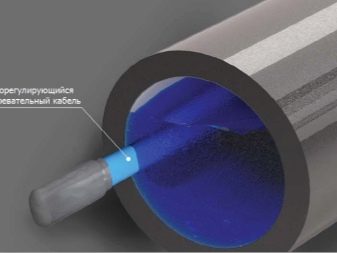

Installation of cable inside the pipeline

It is recommended to install the heating element in the pipe in a situation when it is not possible to carry out heating outside the structure. Often this method is chosen if the plumbing system is already installed underground or used in concrete structures.

Indoor installation has cons when used.

- The passage in the pipe is reduced.

- Thermocable with time covered with bloom, which will further lead to clogging of the structure.

- It adds a new node in the water supply - tee, which is able to reduce the strength of the circuit.

- Installation of the heating cable may only be performed on straight or slightly curved areas of the system. To run a flexible cable through the tees and reinforcement products is prohibited.

The positive aspects of the internal installation include low electrical energy consumption, as well as less laborious dismantling of the structure. It is enough to pull the conductor out of the tee, while the soil does not need to be broken.

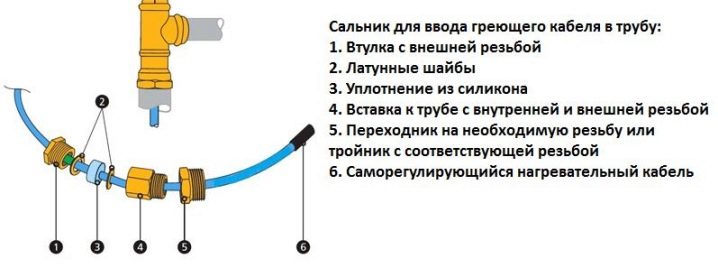

Mounting of the electrical cable is carried out according to the step instructions.

- To begin with, a gland assembly is placed on the conductor for positioning in the pipeline.

- In a certain place of the plumbing system a tee is installed through which the heating element will be introduced.

- The thermal conductor is laid with careful movements to the problem area, which will need to be heated in the future.

- Gland knot twist, hold the seal.

Internal installation of the heating element is nothing complicated. Now we will look in detail about connecting to the electrical network and the performance of thermal insulation of pipes.

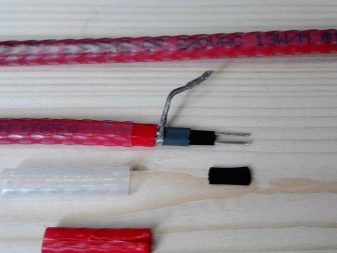

An important point in the installation phase is the insulation of the end face of the heating element. For this purpose, shrink sleeve is used, which will reliably protect the wires from moisture penetration.

Electrical connection

The self-regulating conductor is mainly connected to the power supply cable via a set of heat shrink nipples (crimp couplings). It is a standardized set of nozzles with an adhesive underlayer and contact sleeves for connecting wires.

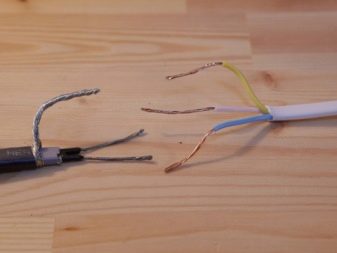

- A power cable is prepared through which the heating element will be connected in the future. The first step is to remove the outer shell.The cut is made with gentle movements in order not to damage the braid.

- After you need to weave the screen. For this purpose, you can use a thin screwdriver or an awl. Now you need to weave the screen in 1 core, which later connect it to the ground.

- Under the sheath is a thermoplastic insulation material, as well as a polyester sheath. They must be removed. As a result, a semiconducting self-regulating matrix remains.

- Stripping of conductive wires is carried out. The wiring is cut off under the connecting electrocontact sleeve. 2 large shrink nipples are worn. A specialized mechanism is necessary to squeeze the liner.

- Determine what distance turned out between the wiring ground and compare it with the size of the pipe. If necessary, you can trim the shrink sleeve to the desired length.

- The casing of the mechanism is performed by means of a building dryer. The conductors of the current are connected to the power supply cable, now it remains to connect the shield to earth.

- The pliers clamp the contacts of the ground wires in the connecting sleeve.A large shrink tube is put on, which needs to be heated with a hair dryer. Connection is ready.

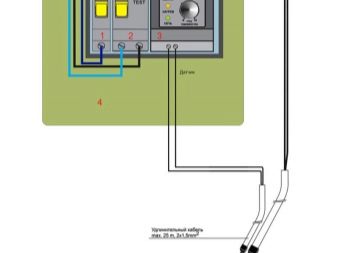

To connect a flexible conductor, it is necessary to connect the heating part with a cold one, which is not heated. For economy and safety of heating the system, experts advise to connect 2 devices: RCD and thermal regulator. The first mechanism will prevent current leaks, and 2 will allow temperature adjustment through a thermal sensor. When connecting a sensor to a thermostat, it is necessary to take into account that most types of heating conductor work only if the size of the plumbing system does not exceed 50 meters. If this condition is not met, the system quickly fails.

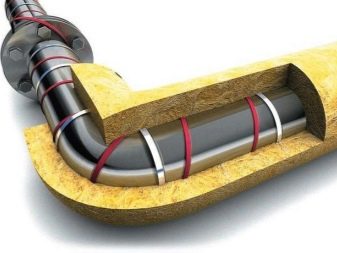

Heat insulation

At the last stage, it is necessary to insulate the pipes for better retention of thermal energy. As a warming material, you can use specialized cylinders, which have a cut in one side. They can be made of mineral wool, polyurethane foam, polystyrene foam. You must select a suitable variation and wrap the pipeline.

The thermal insulation layer not only keeps the body inside the system, but also protects the conductor from mechanical damage. (if outdoor installation is performed). The thickness of the insulation material should be not less than 20 mm for half-inch pipe systems, 30 mm for inch, 50 and 65 mm for other parameters.

Installing a heating unit in the plumbing system allows you to provide the necessary temperature for a particular area. In order not to regret the spent material resources and forces, at the planning stage it is necessary to take into account the climatic conditions and the technical characteristics of the building in which the self-regulating element will be installed.

How to lay a self-regulating cable for pipes, see the following video.