Profile bending: effective and safe methods

Bending of pipes is made in construction, utilities, energy, oil and gas, water and many other areas with the installation of pipeline systems, the manufacture of building structures, products for various needs of the population and urban households. In general, it’s impossible to count everything, but it’s good to know how to bend pipes. Other methods can be useful in the household.

Types of products

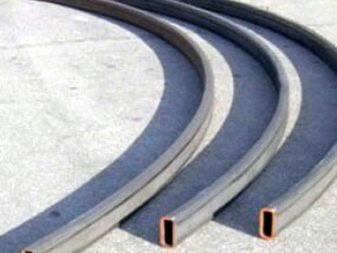

Products of profile pipe-rolling are represented by a series of metal pipes of various configurations in cross section of the cross-section.They can be very different, but different from the round, that is, non-standard shape: ovoid and flat-oval, rectangular, often having a square configuration with rounded corners, and even many-sided. Round is used narrowly - mainly for the construction of water supply and sewer networks.

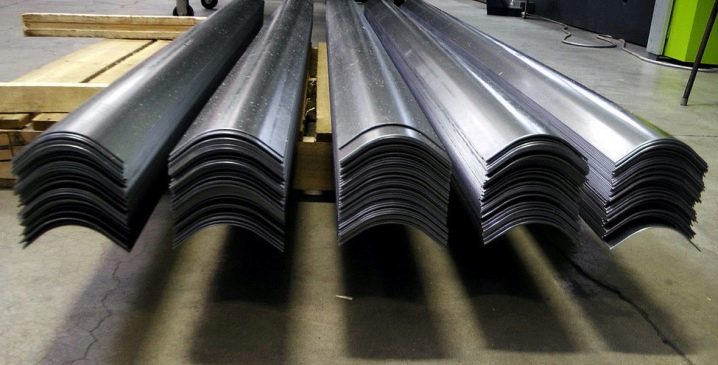

The profiles of square and rectangular shapes are more in demand on the market. Due to the fact that it is easiest to fasten any material on a flat wall, they are popularly used in the construction of industrial and domestic facilities. Such an element has increased strength and is a stiffener in the building. The profile copes well with the moment loads (bending loads), which is why they are a good choice for use in the construction of the metal frame of buildings of various purposes.

Products are produced in a wide range of sizes, depending on the type of metal: for example, copper can be found in a series of thick-walled profiles of a large section area, unlike aluminum. Furniture is made from thin-walled stainless steel products.Material for the manufacture often becomes high or low alloy steel. Square-pipes differ from each other in the production method: they are electrowelded, cold-rolled and hot-rolled, seamless. A special feature of welding is the presence of an inert gas medium, but there is another way - induction welding.

Special features

Products from a profile pipe do not have a large weight, so it is possible to easily and in a short period of time create non-heavy arched structures. It is indispensable for the construction of various greenhouses and low cost greenhouses.

Construction with the use of metal frameworks is important not only for summer residents and gardeners. Often, the need to use such building materials arises in urban residents, if they wish to arrange a private territory adjacent to the house. For example, quickly and inexpensively install a gazebo, a covered terrace or a polycarbonate canopy - this is quite common in modern cities.

Profileprokat also used in the construction of stairs and railings. It often happens that the standard configuration is not suitable for a certain type of design,here there is a need for bending with the use of special equipment or some tricks. About it a little later.

Pipes manufactured in production have certain specified geometrical parameters, which subsequently have an impact on plastic characteristics. The wall thickness and transverse area affects such a parameter as the minimum bending radius. It indicates the rounding value, at which no mechanical damage will occur.

Deformation of steel products is not as simple as it may seem at first glance. It requires a certain set of knowledge, the ability to choose the right technology and equipment. Only giving the required appearance is not the essence of our work, while performing it, it is necessary to preserve important parameters - wall thickness, maintain linear dimensions, and not disrupt operational capabilities. The following loads act on the workpiece as a result of application of force: on the inner section - compression force, on the outer (outer) - tensile force. Perceiving their action, the element is deformed, receiving a full or partial bend.

But due to the peculiarities of the details, we have to face some problems.

- Loss of alignment due to shape change. This means that the tubular segments may be in different planes, which is unacceptable. Experts the reason for this phenomenon emit the wrong choice of the method of bending.

- The rupture of the outer wall. In the process of stretching the metal bursts, if the load exceeds the amount that it can withstand.

- As a result of the uneven contraction of the inner wall, folds resembling a corrugation are formed on it.

Return to the previous form of low-alloyed and carbon alloys having a high coefficient of elasticity. After bending, many elements seem to be “springy”, and the product after such a phenomenon has to be re-adjusted to the desired dimensions, which can complicate the work. To get rid of unwanted problems and additional work, it is necessary to determine the value of the plastic moment of resistance of the material, and taking this parameter into account, carry out the bending procedure. It should be noted that the smaller the angle, the smaller the elastic consequence.

Instruments

Portable ProfileBibs

It is very convenient to bend immediately on the site of installation. To accomplish this goal it is more rational to use a portable pipe bender.

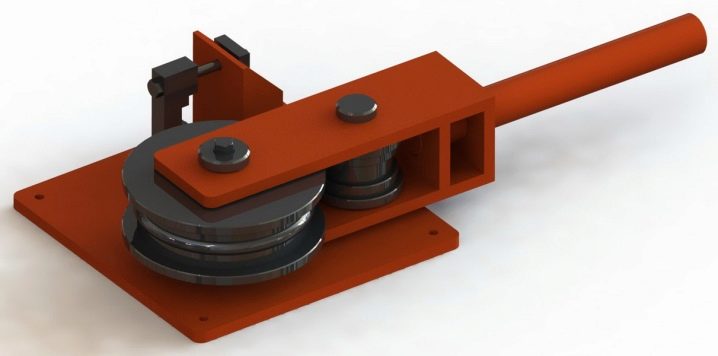

Lever ProfileBibs

When using this device, bending of the profile occurs exclusively through the mechanical force of a person. This is made possible by the presence of a leverage on the application of a force of considerable magnitude. Parts made of plastic metals and stainless steel, the cross section of which is no more than two centimeters, are able to bend to 180 degrees.

Pipe bending machines

Such a tool consists of the following parts:

- bending element;

- a moving chopik connected to a bending shoe;

- Two supporting parts rotating around their own axes, on which the bent part is placed.

The device can be with a mechanical (screw) configuration, hydraulic with manual control, or with an electric drive. Such easily portable devices easily bend a 90-degree angle to metal products made of plastic material with a cross section of up to 100 mm.

Hydraulic

In production and domestic use, hydraulic devices with manual or mechanical type of exposure are more common.

We list their advantages:

- Large volumes that can be performed compared to a mechanical profilegib.

- An opportunity to choose the vertical or horizontal pipe bender based on conditions of working space and convenience in work.

- Ease of replacement of punches (spare parts for specifying the angle).

- The existence of devices that simultaneously bend several installations at once, which significantly reduces the time spent.

- The elimination of difficulties in the work even for beginners.

- The presence of a pipe protecting against slipping and devices warning against injury.

- The simplicity of self-repair in the home.

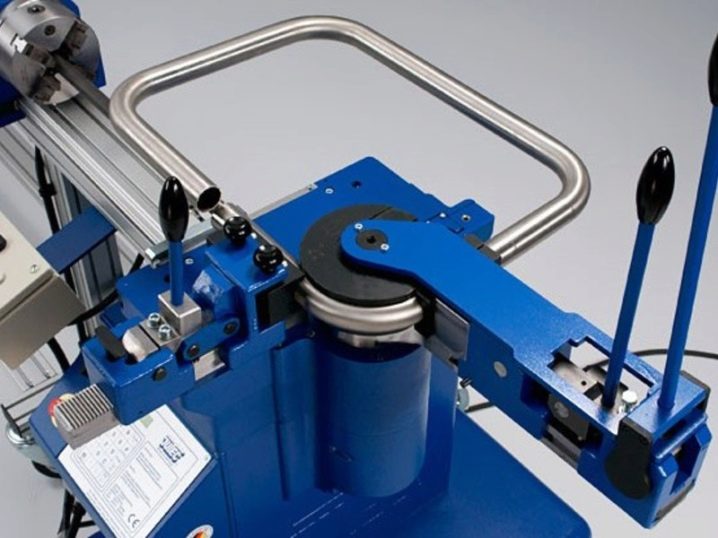

Electric pipe benders

They bend the metal products placed on the bending components, which, depending on the radius, it is possible to change. On such devices there is a swivel mandrel, with the help of which they change the product. In the absence of electrical power, the device operates from an internal battery.

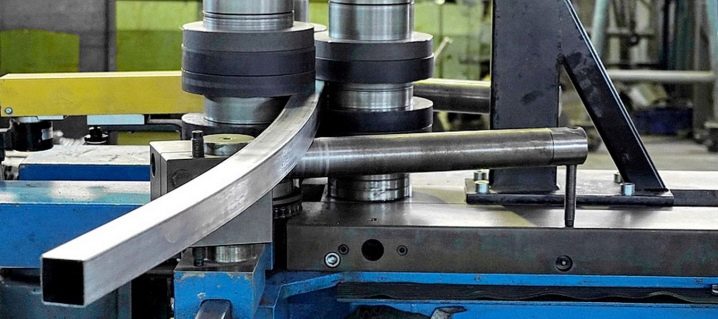

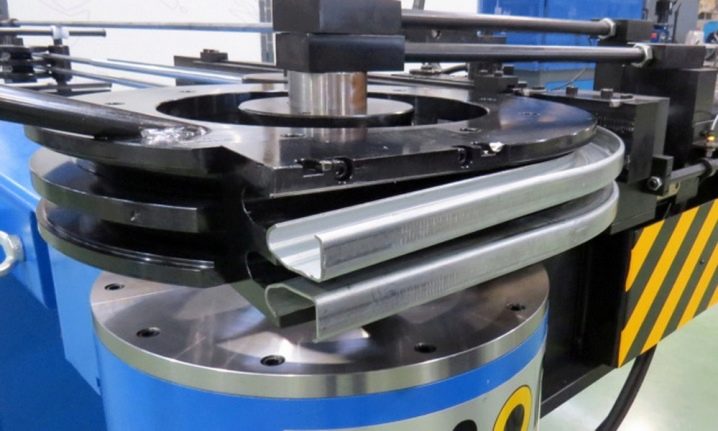

Machine bending

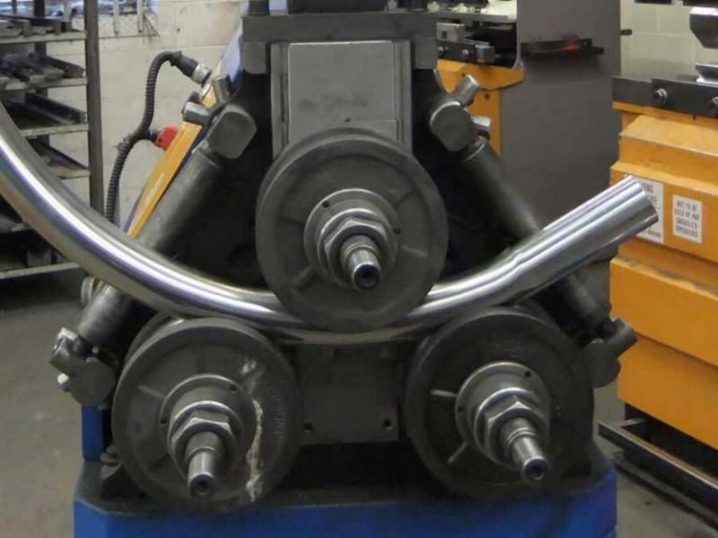

When the cold method, called rolling, use a standard roller mill, having three roller bearing (roller). The shape and radius of the bend at the exit depends on the choice and installation of the required shape and size. This machine is able to give a bend to parts from any material and any configuration - it copes not only with square, but also with triangular sections and more complicated. With the help of such equipment it is possible to deform the workpiece of maximum length, which is very important, and also to get a product bent 360 degrees (in a ring). The method of rolling is defined as the most common type of deformation, therefore, the equipment belongs to the universal.

In addition, the machine allows you to set a specific angle, which increases the accuracy during installation. The angle can be controlled manually or on CNC machines (with information-numerical control) set numerically with the subsequent process control. On such machines, the production of heated towel rails in each house is carried out. In the manufacture of pipes for heated floors also need to contact the machine equipment.It has a large scale production of components for spiral staircases, porches, various forms of fencing and decorative elements that serve simply to decorate the interior.

The positive sides of such devices are the following possibilities.

- The ability to avoid inaccuracies when working with subtle details, in contrast to manual devices, often showing a sharp bend instead of a smooth curved line in outline.

- Accuracy. Mandatory criterion in a serious construction is this item. Again, no other types of mechanisms and methods designed for these types of work are not compared with professional machines. In the manufacture of the sale is also impossible to do without this advantage.

- Reach with high speed to get the finished product. After all, the average speed of the profile bending is 0.2-0.3 m / s.

- Autonomy. The ability of equipment to work without human intervention in our century is no longer an innovation, but only a useful one, but somewhere is an essential addition to other characteristics.

- The potential of doing large volumes.

There are stationary profile-bending units that are powered from 380 V mains, such are not suitable for personal use. In order not to make an erroneous purchase, you need to carefully study the characteristics of the product. Rollforming installation is a very effective thing, but also expensive. In addition, the use of such equipment is possible only in the factory.

Often, to obtain a higher-quality part, mandrel bending is used, which is feasible when working with virtually any device. About her in order. Dorn is a rigid or flexible part, placed inside the bendable segment in the place of further bending. After changing the shape of the product it turns out smooth, has no folds and other defects. Such a set of advantages of the methodology is followed by a significant reduction in the rejection rate at the output of products.

Ways

There are two methods of radial profile bending: cold and hot (with preheating). In addition to the separation of methods by temperature type, there are many more types related to mechanization and the equipment used, for example, bending:

- running in;

- winding;

- dragging;

- method of three-roller rolling;

- using two supports;

- stretching method;

- using internal hydrostatic pressure;

- broach through the die plate with a curved axis;

- through copiers.

The choice depends on whether the hot or cold option will be work.

With a cold performance, this can be accomplished with several options.

- running in (diameter up to 70 mm; with low requirements for roundness of the section at the bend);

- winding (diameter up to 20 mm);

- dragging (for thin-walled);

- with two supports (diameter up to 300 mm).

The cold one is suitable for a small diameter, and the cold method will not be able to bend the product, for example, at an angle of 45 degrees. Heating improves the deformation properties of the metal, and due to the increase in ductility it becomes easier to work. Preheating does not cause problems with marriage in the form of cracks, residual damage, corrugations and other consequences. At large industries heating is produced by high-frequency currents (HDTV). In the presence of a small section, the use of hand-held portable tools is feasible, for a large section such an alternative is not applicable, here mechanized equipment is used.

In addition to these nuances, it is worth remembering the phenomenon of elastic consequences.It means the ability to partially return the workpiece after deformation to its former shape. The value depends on the type of material and dimensions of the profile, on the temperature method and the type of work - manually or on special equipment.

In addition to the above techniques, in the home, you can perform the process with the use of equipment that is easy to create yourself. Depending on the initial characteristics and the desired circuit, there are enough options to save on expensive equipment. Below are some examples.

Homemade roller-based mechanism

This is the closest version to the original roller profilegib. To create it you will need to purchase 2-4 videos. It should be noted that their width should slightly exceed the width of the product itself. To get the result you need to fix it horizontally, so that the rollers have the opportunity to rotate freely, they must be at such a distance from each other so as not to interfere with the pipe passing through the system without obstacles.

This do-it-yourself assistant will allow you to bend the product around the circumference.If there is a need to achieve a certain angle, the system must consist of three rotating cylinders. While one of them is desirable to leave adjustable. The reinforcement element is placed between the rollers, and the person, controlling the process, starts scrolling.

Using the "grinder" and welding machine

If the construction of such a mechanism is impossible due to finances, time, skills or other reasons, there are more understandable variations. But the application of the welding method significantly takes time and requires laboriousness.

The sequence of works is as follows.

- First of all, it is recommended to calculate the allowable and determine for yourself the required bending radius.

- Apply along the product transverse marks, which will be further cut for further connection. The smoother the transition in the bent part is needed, the more often it is necessary to make marks.

- Make cuts of three selected sides (edges) on the drawn marks. The fourth side should not be touched.

- After cutting, bend the product to the desired curvature. to improve accuracy, you can make a piece.For example, prepare a wooden part with the desired bend. Attach the non-sawn side of the rolled to the curved edge of the template, fasten, then bend the field to match the bending of the template.

- Weld the saws carefully and reliably.

- Weld the areas carefully, so that the surface of the part becomes smooth, without protruding seams.

With a large area of the cut, this method, in the absence of others, will be suitable as never before. But this method is applicable for individual works, so it should not be applied to those who need to deform a large number of elements. In this case, it may be more rational to think about creating a roller bender.

Spring for bending

All masters know about this method. Its essence consists in the following: a special spring of square section made of steel wire is placed inside the pipe in the place where it is necessary to obtain a bend. The spring will serve as a mandrel, its cross section should be 1-2 millimeters smaller than the internal cross section. Using a blowtorch, the place of the further bend is heated, applied to the blank with a suitable bend radius and, using force, do not press sharply until the desired curvature is obtained.This method is quite simple, but using it during the work, it is recommended to carefully observe safety precautions: work in special gloves and use tongs.

Tips

About the intricacies of the hot method

To successfully bend the pipe in a hot way, you should use a filler made of sand. The ideal option is medium-grained sand - building or river. If it is not possible to use just this, as a last resort, the material from the children's sandbox, but previously cleaned of unnecessary content, will also be suitable. To be cleaned of unwanted impurities, it is necessary to sift through a sieve with holes of about 2 millimeters. After the first screening on the sieve will remain large items - twigs and pebbles. Their presence in the filler is extremely undesirable, because when heated, they can affect the relief and form a bulge. Next, you need to sift the future filler a second time, already through a fine sieve to get rid of too fine sand. After sifting, the sand is calcined.

The pipe, at the place where the bending will occur, is annealed. Before falling asleep filler should take care of the plugs,which will not allow him to get enough sleep. It is recommended to make them out of wood, so that they fit snugly to the walls. In one of the plugs, it is necessary to make grooves through which hot air must come out. Such openings are located on each side, i.e., there should be four square sections. After installing the plug without holes through the funnel, you can begin filling the filler. At the same time periodically should knock part to seal the sand. After securing the second plug, you can mark the bend, fix the part and produce uniform heating. If the part is welded, the seam should be located outside the bend in order to avoid its divergence. The color of the ready for the bending part must be red-cherry color, and from the pipe - to fly off the scale.

It is recommended to bend metal products from the first heating, otherwise it may lead to loss of strength and fracture of the element. If, after cooling, wooden plugs are difficult to remove, they can be set on fire, and after burning, pour out sand.

About the intricacies of the cold method

The subtleties of the cold method:

- Without the use of special tools and heating in the cold season, the process of bending can be greatly facilitated. For this, alternatively to the sand method, water is used as a filler. After filling and installation of the plugs, the product is exposed to frost for the time necessary for the liquid to completely freeze. In the light of the physical properties of frozen water, bending will be easier.

- In order to avoid injuries of the brushes and to reduce the applied forces, it is proposed to use a profile pipe with a section slightly more bent. For this, a larger profile is worn on the edges of the smaller one, thus increasing the shoulder strength.

- Masters are advised to make a trial bend on an unnecessary part of the product, this will give an idea of its physical properties and prevent errors in subsequent attempts.

Summarizing the above, we can draw conclusions about how effective this or that method will be. It is more expedient to turn to professionals who have equipment specially designed for this purpose in order to obtain a better result and save time.If the work involves multiple bending of products, then why not think about purchasing special equipment, and also, perhaps, about providing bending services to other people. In this case, you can quickly pay for the device.

Alternatively, there is the option of renting a pipe bending device for a specific time. If there is such an option in your city, then you will save time and you will not have to overpay for expensive services of companies.

For information on how to bend a pipe without a pipe bender for a canopy, see the following video.