Types of pipe clamps

Pipe clamps are an integral part of water mains, sewer pipes and heating systems. Despite the simple design and minimal cost, clamps play an important role in the arrangement of networks, construction and laying of communications.

Design features and purpose

Clamps are made in the form of plates of a rounded shape, wrapping around the pipe and holding them with bolts. For a more tight fixation of the pipeline and to reduce the mechanical load on the fasteners, the design provides for sealing gaskets made of shaped rubber or food rubber. It evenly embraces the pipeline and protects it from damage when tightening the staples.On some models, the tightening nuts also have gaskets and sealing elements, providing a more tight fit of the elements to each other.

The use of clamps is very extensive. The elements are used for reliable fixation of water and heating pipes to the walls, which provides the structure with complete immobility and is often a necessary condition for arranging communications. Clamps are widely used as sealing clips mounted on weak joints and leak sections. Staples press the gaskets tightly to the damaged area and eliminate leakage. Products can be superimposed on vertical and horizontal pipelines and installed at any temperature and humidity. Due to the rubber seal, models are often used to ground the plumbing system.

Often with the help of clamps block the hole from the tie-in, the need for which at the moment no longer exists. The detail copes with corrosion damage, cracks of small and medium size, and is indispensable for fractures of pipes.In these cases, a special type of clamps is used, fixed to the walls or ceilings and supporting the damaged area. Fasteners can be installed on reinforced concrete, plastic, cast iron, steel, copper and aluminum pipelines, and can replace the welding process. The only restriction on the use of clamps is their installation at the cross joints and curved sections of the pipeline. In such curvilinear designs, the use of clamps is inefficient.

The main difference between the clamps from fittings and other shaped parts of the pipeline is the time of their installation. And if other elements are mounted into the system during its formation, the clamps are installed on the already finished structure and complete the stage of its installation. One of the important operational properties of the clamps is their ability to allow longitudinal movement of pipes, resulting from linear expansion. However, lateral displacement is not possible. Due to this quality, the pipeline can react to changes in the temperature in the network, while remaining a fixed and rigid structure.

Despite the relative simplicity of the device, strict requirements of GOST are imposed on all types of clamps. This is due to the functional significance of the models and their significant impact on the overall strength of the trunk systems. For each type of fasteners have their own standards. Thus, the marking 24137 80 regulates a number of requirements for metal products in the form of a horseshoe, a ring and two half-rings. The document specifies in detail the sizes, steel grade, maximum permissible loads and the value of the limit tightening. Each product must include a fastening in the form of a self-tapping stud, plastic dowel or connecting nut. Polymer models meet the requirements of GOST 17679 80, which also spelled out the design characteristics and features of the use of plastic products.

Species

Clamps are presented on the construction market in a wide range. Models are produced in a wide variety of sizes and are divided according to such characteristics as the method of fixation, the presence of a sealant, the shape, the material of manufacture and purpose.

According to the material manufacturing products are divided into plastic and steel. Moreover, the steel elements can be made with or without galvanizing. In comparison with plastic models, steel clamps are considered more popular and popular. This is due to the low cost of products, good tensile strength of the metal and high strength. The disadvantage of metal clamps is the low resistance of non-galvanized models to corrosive processes. Therefore, in cases where the installation of clamps is planned in excessively humid rooms, you should choose models of stainless steel or clamps coated with zinc.

Plastic options are characterized by increased elasticity, high resistance to vibrations and the ability to create a movable fixation. Models can be used for fixing a pipeline with a diameter of not more than 10 cm.

Plastic clamps are not suitable for repairs. The disadvantages of the models is the impossibility of their use as a suspension when the pipeline is broken, as well as low resistance to stretching.

Depending on the tasks assigned to them, the clamps are divided into spiral, power, wire, worm, tube and mortise options.

Spiral hose clamp is a fairly common device and is designed for rigid fixation of pipes in the system.

Power has the form of a tape with holes for bolts and is indispensable when working on highways with high working pressure, at pumping stations, pneumatic and hydraulic systems.

Wire clamps presented in the form of one or more rings of steel, equipped with tightening fasteners. The model is designed for corrugated pipes and is indispensable for their fixation with strong movements.

Worm model is a steel strip with a track, equipped with teeth and screws for tightening. The model is used in the arrangement of heating systems, as well as as a fixing mechanism for pipelines exposed to severe vibrations.

Pipe Clamps presented in the form of rings with brackets and installed to secure the pipeline in cases when it is necessary to reduce the internal stress in the system during the repair.

Spring clamp It has a fairly narrow specialization and is used on pipes subject to linear expansion.

Mortise, or saddle, clamp with a tap is a more complex mechanism and is designed to be installed at the branch points of the pipeline. Its main difference from traditional models is the presence of a coupling, equipped with threaded nozzles, which allows you to embed the clamp into the system and in the short term to connect an additional branch. The tightness of such a connection is provided by a gasket inside the clamp and made of profiled rubber.

Swivel modelsAlso known as hinged locks, they are used to install scaffolding and are used when fastening diagonal struts. Thanks to swivel collars, all elements can be fixed at any angle, which gives additional structural strength and ensures its stability.

By fixing type, all clamps are divided into two types:

- The first are models that form a rigid type of fastening, in which the pipe becomes completely stationary. Crimp brackets of such products are securely tightened with bolts,and the clamp itself is firmly attached to the wall. This type of fastening is used on sections of pipe bends and in the presence of branching.

- The second type includes models with a movable mount, used for fixing heating pipes and hot water supply. The specificity of the mounting does not create obstacles to the extension and contraction of the pipeline and ensures its longitudinal mobility. As a result, an optimal line voltage is created, significantly extending the life of the networks.

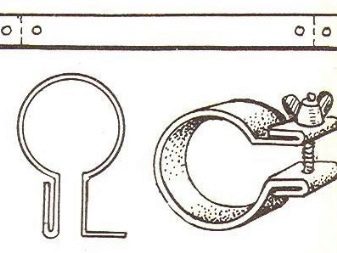

Structurally clamps are represented by several types:

- split ring formed in the form of a circle and having one fastening mechanism fixed by a bolt;

- a ring consisting of two semicircular plates and having ears of fastening on both sides;

- tape, folded ring and having several positions for fixation;

- U-shaped model, often made of plastic, equipped with a snap-lock and capable of being fixed in a rigid and mobile manner at the same time.

Equipment

Clamps can be sold with or without rubber seals. As a gasket, microporous types of rubber are used, which provide almost complete damping of vibration waves,arising from the movement of water within the system. In addition, the gasket significantly reduces noise and makes the joint more airtight. The use of clamps with rubber seals is advisable when installing plumbing in residential premises, carrying out repairs, as well as when working with systems into which coolant is supplied under high pressure.

If the installation of the pipeline is carried out in rooms to which special sanitary and hygienic requirements are imposed, gaskets are placed as a sealant.

Clamps are presented in a wide variety of sizes, which greatly facilitates their choice and allows you to purchase a model for pipes of any section. Models are available in the range of 14-540 mm and cover almost the entire size range of pipes, including products of large diameter.

Independent production

If it is impossible to purchase a factory clamp, it is not difficult to make the fasteners with your own hands. Crimping element can be made of galvanized tin plate with a thickness of 1 mm. To do this, cut a strip, the width of which can be 4-8 cm. To determine the length, measure the diameter of the pipe and multiply by 3.14.The resulting numeric value will be the length of the bar. To this value you need to add another 3-4 cm, necessary for the formation of the lugs, and then cut the workpiece.

Two holes should be drilled on the sides of the strip at a distance of 5-7 mm from the edge. In case production of a wide clamp is planned, the number of holes should be increased. So, for products up to 6 cm wide, two fasteners are enough, whereas for a model 8 cm wide, 3 bolts are required. After checking for matching the holes made in the clamp, insert the gasket and tighten the bolt.

To ensure a more tight connection, it is recommended that the rubber strip be pre-glued to the metal. Next, using the finished bracket, you should tie the pipe, then connect the ears with each other and pull off the bolt.

A simple device, low cost and easy installation greatly expand the scope of use of clamps, favorably distinguish them from other fasteners and allow you to install them yourself.

On the stainless steel clamp for pipe mounting, see the following video.