Plugs for profile pipes: varieties and their purpose

When installing pipelines for different purposes often use plugs for shaped pipes. Thanks to such simple, at first glance, details, it is possible not only to drown the pipes, but also to solve many other equally important issues.

Special features

A distinctive feature of profile pipes is their square or rectangular section, as well as oval. They are rarely used for the supply / output of water, but quite often chosen for construction purposes and during repair work. At the end of the installation process, one or both ends of the profile pipe remain open, that is, they are not covered with anything. But the ends must be closed so that dust, dirt and other foreign objects do not get inside the pipe.For these purposes, and provided stubs.

At the moment, modern industry supplies to the market a wide range of different tips for pipes. They differ in the material performance, shape, method of connection, size and scope. But despite a number of distinctive characteristics, all plugs for profile pipes perform the following tasks:

- They protect pipes from penetration of moisture and, therefore, prevent the development of corrosion in metal structures.

- Protect from vandalism (possible use of them instead of a tank for collecting garbage).

- Protect pipes from their use by insects as housing (it happens to swarms of bees, wasps and hornets).

- PVC plugs are often used for installation in furniture designs. They protect the floor from damage to the integrity of their cover.

- Perform sealing pipes that were selected for the construction of fences.

- They protect the inside of the pipes from mechanical deformations that may occur as a result of transportation or storage.

- Are beautiful decor.

According to the rules, plugs for the ends are chosen from the same material as the pipes.Metal models are most often made from stainless steel or ordinary steel, aluminum is also used. They are installed in different ways and welding is not always required for installation, because, thanks to an impressive range, you can choose a fitting with a simpler installation method.

No less demanded are products made of polymer (polyethylene, polypropylene, polyvinyl chloride are used). The most popular raw material for the production of plugs is polyethylene. This material is also the cheapest, which in some way determines the popularity of traffic jams from it. PVC is used for pipes with a wall thickness of more than 1 mm. Such elements withstand temperature jumps from minus 30 degrees to plus 60.

The most expensive are stubs, chrome plating. They are often used for decoration of various household items.

On sale you can also find pneumatic plugs made of rubber. For their installation using a simple pump. With the help of such silencers, it is possible to eliminate an accident on the pipeline in a matter of minutes, to be used for temporary jamming of pipes that are under repair.

Types of plugs a lot.Their classification is based on a number of characteristics.

Production Material:

- Steel traffic jams. Characterized by durability, withstand high pressure.

- Aluminum. Resistant to aggressive media, nonferrous metals are found in the composition.

- Chrome plated. Provide an attractive appearance to profile pipes, increase the resistance of products to the corrosion process.

- Polymer. Used for heating and ventilation systems, pipes for water supply / removal. There are restrictions on the temperature of operation.

- From composite materials. They are based on plastic, glass or ceramics. Such silencers are lightweight, heat resistant and very durable; in certain situations they are superior to metal plugs. In everyday life are not used. Found their use in rocket and aircraft construction.

- Rubber. The basis is rubber or its synthetic substitute. Characterized by low cost. Created for temporary use.

- Wood. It is used extremely rarely, as products from natural raw materials are more often intact. Wooden tips used in the manufacture of eaves, railings to wooden stairs.

- Fabric Used in ventilation systems.Passing through the air, detain garbage.

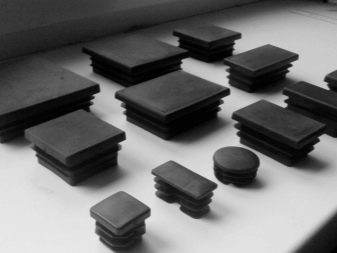

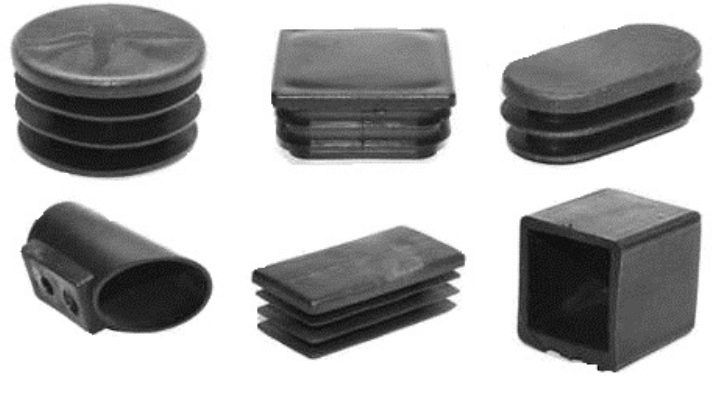

Section shape:

- round;

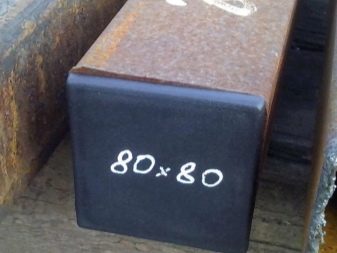

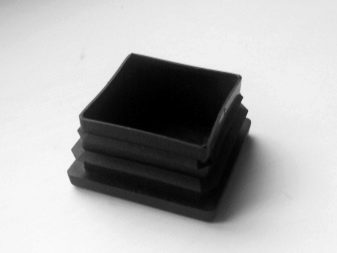

- square;

- rectangular;

- polygonal.

Installation Type:

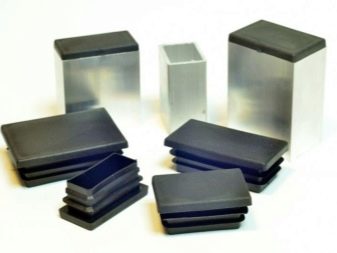

- Internal. They are mounted inside the pipe; only a small part of the dimensions corresponding to the edges of the pipe remains outside.

- Outdoor Like a cap for a pen envelop the pipe around its perimeter. This fitting is located outside the profile pipe.

Fastening method:

- Pneumatic. Internal silencers made of stretchable material, such as rubber. Placed inside the pipe, these products increase in volume. This is due to the pressure inside. Such fittings resemble balloons. The latter increase in volume when they are inflated. Something similar happens with pneumatic plugs. The increased silencer is securely fixed inside the pipe; it is rather difficult to remove. For profile pipes, this mounting option is practically not used.

- Non-removable. Made of metal. With their own hands they can be fixed by welding. Such products are considered one of the most reliable, but they have a significant drawback - it is impossible to remove them after fixation.

- Flanged (removable).On the pipe and plugs there are holes into which bolts or special rivets are screwed. The installation process is quite time-consuming, but such a fitting can be removed at any time. Raw materials for manufacturing - metal or plastic.

- Cap. These elements are used in cases when the structure is not affected by strong mechanical loads, and the plug needs to be removed over time or it is needed for frequent removal / donning, for example, a fitting for closing the eaves.

Design:

- internal plugs;

- external (end).

End rivets made of plastic are convenient because they protect both ends of the pipe at the same time. The design of such fittings is quite simple - they are put on a pipe cut like a cap on a handle. But it is precisely this fact that makes the fastening of external plastic silencers extremely unreliable, therefore they are used only in cases when it is necessary to temporarily protect the inside of the pipes during their storage or transportation.

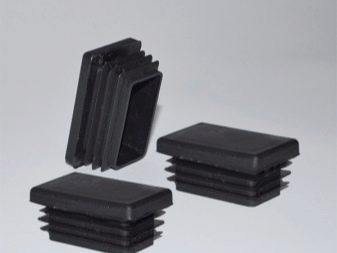

Plastic fittings with internal fastening, in addition to the protective function, perform the function of decor. These centering products look very neat,and due to the presence of special ribs fixed on the pipe is very durable.

Special types of tips are also distinguished:

- pneumatic plugs;

- mechanical models;

- oil and petrol resistant.

The first plugs are also divided into high-temperature silencers, multi-dimensional and with established standard diameters. The plug of the second modification is made of steel, aluminum, polymer, due to which these fittings are resistant to many chemically aggressive media. The third version differs in that Kevlar is used for additional reinforcement of such plugs.

The type of plugs designed for pipelines operating under pressure in the range of 10-25 atmospheres is also produced.

Scope of application

Locking components for oval, square, and rectangular pipes are required for both permanent and short-term plugs of the ends of oil and gas pipelines, water transportation systems, and aggressive connections. In addition, parts for jamming are needed for installation on household and industrial equipment, which is under high pressure.

Tips for the ends have found their place in the construction, furniture craft, they are also in demand in ventilation systems. These products often carry artistic value for gates, pillars and fences, apartment and garden furniture.

Plastic silencers are used almost everywhere in places where metal and plastic pipes are installed: in the manufacture of racks and various pieces of furniture, gazebos and pavilions, greenhouses and canopies, garages, playgrounds and all equipment for children's leisure, basketball racks, gates for hockey and basketball and so on.

Tips

When work is carried out with shaped pipes, plugs for their ends are selected taking into account the place of use of the pipes, their main material and the color range of the structure. In the case when the pipe should be closed as tightly as possible, and its end will be under conditions of constant pressure, it is better to choose a simple metal cap.

If the effect of pressure is not provided, then you can do with plastic parts that can be selected regardless of the material of the pipeline. If flanges are purchased for transporting shaped pipes or their presence is required for a short period of time, it is better to choose external plastic plugs.Their installation and removal are quite simple, and their financial costs are moderate.

If long-term use of plugs is expected, it is worth using internal products. After their shrinkage, it is necessary to check the integrity of the structure. There should be no cracks, breaks and other deformations in the plastic traffic jams. In the case when the financial side of the issue is of paramount importance or there is no need to use steel parts, it is better to stop the choice on PVC tips.

A plug / silencer / plug / lug is an important and sometimes irreplaceable piping object. Due to the high level of preparation of modern production, the variety of these products allows you to choose a product for closing the pipe end with the necessary aesthetic qualities and operational capabilities.

Recommendations from professionals who will help you choose tips for shaped pipes look like this:

- It is better not to use rubber and plastic tips on hot water and heating systems. Constantly being under the influence of elevated temperature, such elements can be significantly deformed.It is better to spend a large amount, but to buy metal plugs that are resistant to various negative influences.

- Pneumatic plugs are not suitable for gas mains, and threaded versions are also unacceptable. They do not provide the necessary degree of sealing design.

- In the case when the tip is needed for a long period of operation, it is better to give preference to flange or elliptical models.

- The section of the pipe and the shape of the tube for it should always be the same.

- For pipes intended for wells, it is necessary to mount a special type of plugs. They are mounted on the lower end of the pipe systems. Such silencers are needed to drain the fluid into the body of the well.

See why the PVC caps for profile pipes are better than plastic, see the following video.