Pipe clamps: types, scope and installation technology

Pipe clamps are used everywhere, they can be used to subdue a broken pipeline, while keeping within a small amount. For this purpose, fasteners of various shapes and made of different materials are used. The method of securing the pipe clamps is simple, but it has many small nuances. For high-quality work with clamps, it is worth exploring their specifics in more detail.

Device

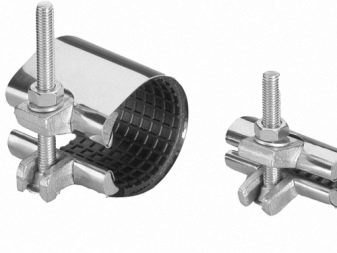

The clamp is a product in the form of a thin plate of rounded shape. These plates clasp the pipe and bolt.The clamp is made mainly of metal, the plastic versions are less strong and durable, they hold the tensile pressure worse, but they are more flexible and resistant to corrosion.

Often in the design includes a sealing element, often rubber. It helps to tighten the pipe tightly - it enhances the insulating function of the product and reduces the mechanical damage to the clamp and pipe when it is tightened. This option with a rubber seal has less weight.

For more expensive versions, the tightening nut and washer are also fitted with gaskets and sealing elements to increase their efficiency.

Other features of pipe clamps include the following:

- can be used to stop leaks on pipes made of different materials: reinforced concrete, plastic, cast iron, steel and others;

- ease of handling, the clamp can be installed by a person without special skills and knowledge, but only those who are familiar with the technology;

- installation of the clamp replaces the process of welding pipes, which is more expensive and takes more time;

- high reliability;

- through the clamp, the pipe can be connected to different axes;

- resistance to temperature fluctuations and related processesexpansion and contraction of pipes;

- quality products are designed for many years of service and are not inferior to the longevity of the pipe.

Purpose

Clamps are used in almost any violation of the structural integrity of the HDPE pipes from both sluggish destructive processes and short-term intensive, leading to rupture and other damage to highways. They can be used in vertical and horizontal planes, in places with high humidity and temperature, for grounding and to eliminate other problems. Inefficient is the installation in the cross joints and on curved sections.

There are specific situations in which clamps are used, such as:

- you need to close up the "sidebar", in which there is no need for various reasons;

- sealing leaks due to perforation corrosion;

- cracks of various sizes - from minimal to quite significant;

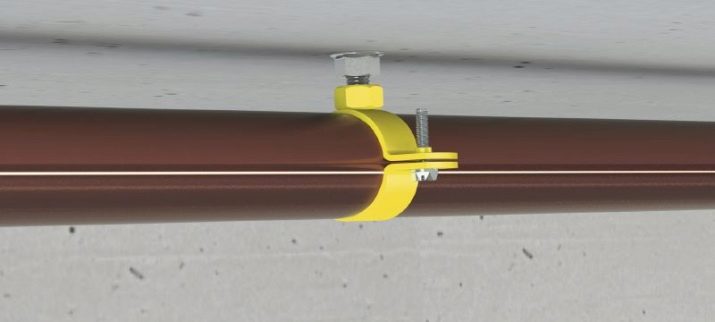

- in case of pipe fractures in the water supply, a special clamp is used, which is attached to the ceiling or wall, supporting the reconstructed part of the water supply system;

- in case of a fistula in a pipe, a collar with an elastic gasket is used, which is pressed into the fistula and stops the leakage;

- as a basic fastening of the pipeline to the wall;

- corrosive damage to pipes of varying degrees.

Classification

Products may be of the following types:

- repair;

- sanitary;

- crimping;

- mortise;

- rubberized;

- connecting;

- pear shaped;

- sprinkler;

- clamping;

- emergency;

- quick clamping;

- quick-detachable and others.

Pipe clamps are subdivided according to various criteria, you can select options such as:

- by appointment;

- on production material;

- according to the type of fixation;

- in form;

- by the presence of gaskets.

To destination

Depending on the specifics of the pipeline on which the clamp is used, and the tasks it performs, there are several types.

- Spiral. This option is often twisted clockwise or counterclockwise, used to strengthen certain sections of the water supply system.

- Power clamp It looks like a ribbon with a bolt. It is used for crimping pipes of round and rectangular format, for rigid and flexible hoses, reinforced hose, as well as for installation of systems with high working pressure - pumping stations, pneumatic and hydraulic systems.

- Reinforced fasteners. It looks like a tape connected by a lock.It is used for crimping reinforced or thick-walled sleeves under high working pressure.

- Wire fasteners look like one or more metal rings with a special tightening fastener. It is used when fixing hoses, thin-walled spiral and corrugated pipes, the operation of which is associated with vibration loads.

- Worm fastener consists of a metal strip and a track with teeth and a screw for tightening. It is used for fixing hoses and pipes in high vibration conditions, as well as in the heating and water supply system.

- Pipe version consists of a bracket and a ring with fasteners. It is used to open the connection of pipes in a certain area when there is a need to reduce the voltage from the inside of the system and fix the location of the pipeline.

- The spring version is used for fastening pipes that supply hot water, and for other structures associated with thermal expansion of the pipeline.

By production material

Depending on the material used pipe clamps can be divided into several groups, among them are the following:

- metal:

- of steel;

- stainless steel;

- from galvanized steel;

- plastic.

By type of fixation

This criterion divides all clamps into two groups.

- The hard type fixes the pipe fixedly. For this, the clamp brackets are firmly tightened with bolts, and in addition, they are attached to the wall. This type of fixation is applied in places of pipe bends, branches of sewer and water mains. For rigid fixation, high-strength hose clamps are necessary to ensure the static position of the pipeline under the influence of negative factors.

- Movable type is used for fixing pipelines.transporting heated liquids, the operation of which is associated with cyclic processes of expansion and contraction.

The specificity of fixing the clamp does not prevent the pipe from changing its dimensions and its mobility; as a result, unnecessary metal stress is not created, it does not collapse, which extends the operational life of the pipeline.

In form

This criterion determines the structural component of the clamp.

There are such common species as:

- split ring is a strip folded in a circle and having one fastening mechanism, which is fixed by a bolt;

- double semiring consists of two plates bent into a semicircle, connected with bolts from both sides;

- The U-shaped clamp consists of a bracket and a strap, which can be fastened either on one side with a nut, and on the other, with a movable connection, or on both sides with nuts. The option with a double bracket is possible, it is convenient to fasten nearby pipes with this fastener;

- clamp-tape is made in the form of a plate, folded in a semicircle with several positions of fixation.

By the presence of gaskets

Steel clamp can be equipped with a gasket, most often used microporous rubber. It provides vibration absorption during fluid movement in a pipeline, reduces the noise level it produces at such moments, and increases the leaktightness of the joint.

The gasket provides many advantages with the only drawback - an increase in the cost of the clamp. Therefore, this addition is used in places where the positive effects of the gasket are necessary.

If these are pipes in the basement that do not experience a special load, it makes no sense to pay more, but if the pipeline passes in close proximity to the dwelling or the liquid is supplied under high pressure, the positive effect pays for the additional costs.

Materials

For the manufacture of clamps used different materials, each of them has its own characteristics. They determine the basic properties of the product, and, consequently, the specifics of their application.

There are several common materials used for the production of clamps.

- Steel is the most common type, which has good strength properties from both tensile and vibration effects. The low cost inherent in these products also contributes to their popularity, but there is a big drawback - it is poor resistance to corrosion processes. As a result, at high humidity or with intensive condensation, steel begins to deteriorate. The iron version today is not very popular.

- Stainless steel has the same positive qualities as ordinary steel, but is not afraid of high humidity and water in general, however, the cost of the material is also higher.

- Plastic is distinguished by high elasticity, which allows you to create not only rigid, but also mobile fixation of the pipe. It resists vibration perfectly, however, the pressure is not as stable as mechanical counterparts, and cannot be used if it is necessary to support the pipe by the suspension when the line is broken.

Another huge plus is the complete absence of corrosion processes, in addition, the cost of such clamps is also low.

Mounting technology

Installing a product is a technologically uncomplicated measure, but requiring accuracy and accuracy.

In general, the whole process can be divided into two stages.

- First, the clamp is wrapped around the pipe at the point of breakthrough, so that the locking mechanism is on the back side of the leak. It is necessary to have the body of the product evenly, coaxially with the pipe for complete sealing and strong fixation. If the clamp is tensioned with parallel displacement, the acting pressure will cause it to loosen and the flow will resume or break it altogether.

- It is necessary to fix the clamp tightly. It is important not to overdo the tightening, excessive stress will cause additional breaking stress in the body of the pipe and clamp, as well as nuts and threads that can be damaged even during installation and they will have to be cut off during dismantling.

Additional parameters include prescriptions regarding the distance at which a metal or plastic clamp can be placed.

In exact terms, it looks like this:

- 65 cm when installed on a hot water pipeline with a diameter of not more than 20 mm;

- 80 cm when fixing the pipeline of hot water supply, in which the temperature of the liquid does not exceed +60 degrees, and the diameter of the pipe - 20 mm;

- 95 cm when fixing on the line supplying hot water with a diameter of not more than 40 mm;

- 110 cm with fasteners on highways supplying cold water with a diameter of 40 mm;

- 160 and 185 cm when fixing water pipes with hot and cold water, having a diameter of 110 mm and more.

When using a clamp, a number of requirements ensuring a high-quality result must be observed, these include the following:

- Standard clamps are used only on the straight pipe from the outside;

- crimped can a pipeline having a diameter of not more than 350 mm;

- the diameter of the clamp can not exceed the diameter of the pipe, the tension of a narrower clamp will lead to excessive stress, which will result in rapid deterioration of the product;

- the gap resulting from the fracture should not exceed 10 mm, and there should be no serious tilt, the maximum deviation of the alignment is not more than 2-3 degrees;

- the clamp must exceed the damage length by at least 15–20 cm; for plastic pipes, this distance increases to 20–30 cm;

- the area of the hole can not exceed 2/3 of the area of the clamp. Otherwise, you need either a more massive clamp, or replacement of a pipe section. It can be a welding of a new piece to replace the cut out old one or to install a section on two bands.

High-quality installation of the clamp on the damaged section of the pipe depends largely on the material from which the clamp is made, and, consequently, its strength.

Particularly important is the degree of conjugation of the surface of the yoke and the pipeline line. With the right choice of product, the patch will serve no less than the original material.

The sequence of installation of the clamp is universal. However, there are additional points depending on the type of fixation chosen.

At installation of collars there are several distinctive moments.

- At rigid fixing of a collar. The technique is characterized by the presence of main support points, which are the junction of the clamp and the surface of the pipe in such a way that any movement relative to each other is excluded.For such fixing the clamp is located near the point of the bell of the case. At the same time involve fittings of various shapes to enhance the strength of fixation.

- With free-form mounting (it is also "floating" or "moving"). Basically for such fastening use plastic clamps with high elasticity, while the clamp itself is not fixed tightly.

An example is the support of metal-plastic pipes in a certain area without reference points, where suspension fasteners are carried out by means of clamps.

When installing the product, the following tools and materials may be needed:

- fitting;

- supports;

- pipes of the corresponding diameter;

- hose clamps, suitable sizes, sometimes with gasket liners;

- brackets and other tools.

If necessary, fix the pipe adjacent to the wall with hose clamps, for example, water or drain, you must do the following:

- throughout the pipe, as well as in the place where the pipe will be located, it is necessary to make marks;

- the marks on the wall are drilled holes for mounting the clamp. The diameter of the drill should be consistent with the thickness of the mounting studs.It is important to observe the same depth of drilling, otherwise the pipeline will not be able to be installed along one axis, which will worsen its performance;

- plastic dowels are hammered into the holes;

- clamps for screed cast-iron structures are fixed with a screwdriver or manually, depending on the type of fasteners;

- the pipe is installed in the clamps, then tightly fixed along the entire length. The tension should be strong, but without surplus, which is especially dangerous for plastic pipes, because they can be deformed or burst.

In the next video you will see the presentation of the IDRA repair clamp to eliminate the leakage of pipes from VALROSA.