Choosing a corrugated PND-pipe

Polymer pipes in most cases are used for water and gas supply of residential and industrial premises. Previously, in order to preserve the integrity of the power or low-voltage cable, a metal or asbestos-cement hose was used. But recently, in view of the greater reliability, the popularity of products made of HDPE.

Special features

During the construction of communication lines inside buildings or in the ground, there is a possibility of defects during operation. To secure the system, pipes made of low-pressure polyethylene are used, which maintain the operability of communications for a long time. Thanks to this technology, the networks are protected from mechanical damage, stray current, the impact of soil, natural disasters.In addition, the characteristics of polyethylene products make it possible not to lay electricity through the air in the territories of frequent storm and gusty winds.

Flexible and lightweight corrugated HDPE products are suitable when laying a network using an open or closed method on any combustible basis. They are intended to build a new electrical system for domestic and other needs, reconstruction activities.

Variants of the cable, relevant for placement in the corrugation of the HDPE:

- power cable having a small cross section;

- telephone;

- computer (network);

- television;

- fire and security alarms;

- lighting;

- control and automation.

Corrugated pipe from HDPE has a number of significant advantages over other products:

- additional protection of power cables;

- high ring stiffness keeps the pipeline from mechanical impact from outside;

- steel wire in the corrugated pipe nozzle facilitates cable pulling;

- difficult cutting, grounding is not required;

- not subject to corrosion processes;

- packed in a small coil;

- It is sold at a low price, due to the manufacture of recycled materials;

- protects against electric shock;

- does not cause ignition to fire in the event of a short circuit;

- has a two-layer system of walls;

- due to the presence of stiffeners and corrugated outer layer, the integrity of the inner smooth layer is not subject to destruction; This feature allows you to use it for laying underground and facilitates the passage of fluid;

- moisture resistant, elastic, it is possible to lay it with bends;

- it is possible to carry out the main inside concrete, plaster, raised floor;

- material production can be metal or plastic;

- transfers heat drops in the interval -20 - + 90 ° С;

- the impact of external aggressive processes is reduced to zero;

- small weight;

- the service life is up to half a century;

- has a nylon broach;

- no problems during transportation;

- no condensation due to low thermal conductivity;

- cathodic protection optional;

- possesses high dielectric characteristics;

- does not burn or emit hazardous substances in the event of heat.

Speaking of disadvantages, it can be noted:

- the corrugation cannot be pulled into several networks of one tube and come into contact with sharp corners;

- to perform the packing work in the correct order, you need to use a non-standard approach;

- during installation you should not forget about some temperature limits, this product is not used in all areas (the product is not used to carry out the DHW system);

- products of HDPE can not be compared for a long service life with iron and steel products;

- The properties of the product are affected by the degree of ultraviolet radiation — remember this before designing schemes based on them that are not provided with additional protection.

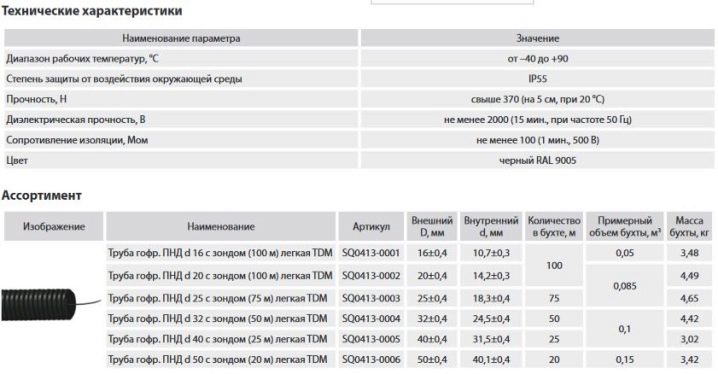

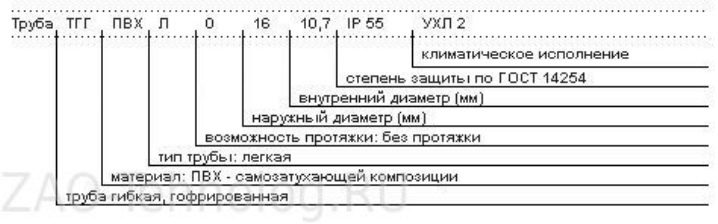

Norms

Technical standards of products give detailed information about the thickness of the product itself, the wall, the color scheme, compliance with GOST, marking data, the number of layers. This product is made in accordance with the following rule: the pipe diameter is directly proportional to the wall thickness (the larger the diameter, the thicker the wall).

The latter characteristic may vary in a large interval. The smallest wall thickness is 2 mm. In this case, the caliber of the tube is 16-50 millimeters.

The maximum thickness is approximately 30 mm, the diameter ranges from 20 to 25 centimeters.The durability of the HDPE pipes can withstand a pressure of 20-38 MPa with a linear expansion coefficient of 140 Pa.

It is worth remembering that not all the laying work by the underground method will require such strong and protected products. In this regard, manufacturers offer a whole range of products for various purposes:

- lungs - able to withstand pressure up to ¼ MPa;

- medium light - maximum 4/10 MPa;

- medium - 6/10 MPa;

- heavy - 1 MPa;

Each sleeve, necessary for laying the line, has a label corresponding to its parameters. This symbol shows the characteristics of a particular product. As well as the marked designations allow to monitor compliance with the quality of a particular pipe:

- "T" is a heavy pipe;

- "ST" - moderate;

- “C” is medium (meaning weight);

- "SL" - medium light;

- "L" - easy.

Information about weight, which is directly proportional to the level of the fortress, is supplemented by data on the diameter and thickness of the walls. To ensure the integrity of the underground thin wire, a cross-sectional area of 1.5-2 mm² is required. Moreover, the amount of cable varies from 1 to 4 pieces.For a cord with a cross section of 6-16 mm², a PND tube with a diameter of 20 to 40 mm is required.

The final results are affected by the number of cables enclosed in the HDPE. So, for three lines, with a cross-sectional area of each 10mm², one should choose a pipe similar to two cables with a cross-sectional area of 25 mm². In the case of conductor cross-section from 35 to 70 mm², a pipe of a larger diameter in the range of 40-50 mm is required

The non-corrugated pipe does not bend and is realized in limited footage: with a diameter of up to 9 cm, the product length is 100-200 meters. As the width of the hole increases, the size of the polyethylene sleeve decreases, for example, by 12 meters each.

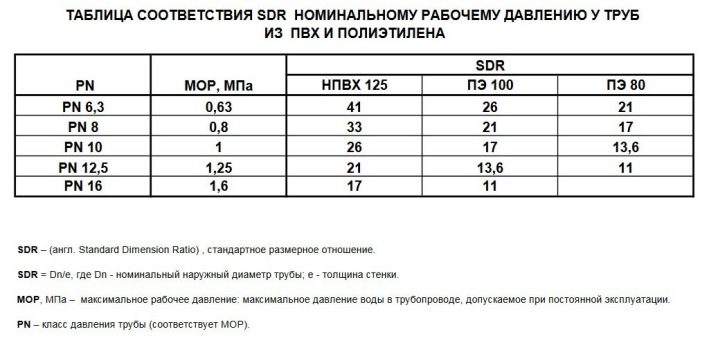

SDR is another important criterion for determining pipe quality. It is calculated by dividing the outer diameter by the wall thickness. If this special coefficient increases, there is a decrease in overall strength.

Installation of technical protective sleeves is similar to the laying of electrical sleeves. The only difference is in purpose and labeling. A pipe of this kind is designed to lay non-electric (sewer, heat-conducting) networks underground.

Product radii range between 1 and 25 centimeters.Like electrical, technical pipes are shipped in a special winding or cut into pieces of 12 meters. Such polyethylene products, in addition to the above objectives, are used in the free-flow scheme of the aqueduct, drainage, land reclamation activities, for irrigation. It is mounted with fittings, adapters, couplings, which are not bent, like a corrugated pipe.

To ensure absolute sealing, special butt welding or compression fitting is applied.

Kinds

Polyethylene products are divided according to the purpose and properties.

The first group includes the following types of products:

- for carrying out a water supply system;

- gas;

- sewage;

- drainage;

- irrigation system;

- technical projects.

In addition, according to this parameter they are divided into:

- PND PE 80 - they are necessary to transport natural combustible gases;

- HDPE PE Prosafe, having a three-colored protective surface, provide resistance to mechanical corrosion.

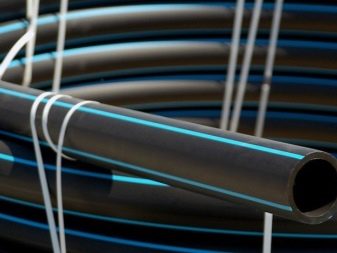

This sample can be laid in the absence of a trench, as well as in its presence without preliminary preparations.Blue pipes are designed to build a cold water supply system, red is used to supply hot water, yellow - for a gas pipeline.

Their main advantage: high resistance to internal pressure drops, and a period of operation up to one hundred years.

Plumbing parts are made in full blue or black with blue stripes along the pipe. Drinking pipelines are made according to a special list of production rules. Pipeline models are yellow or black samples with orange or yellow longitudinal lines.

Pipes for sewage with the use of internal and external systems are produced with ready outlet pipes, allowing connection without fittings.

HDPE products for the implementation of drainage schemes are distinguished by a special construction, corrugated, which perfectly impedes the approach of fluid to buildings and foundations.

Irrigation mechanisms serve to carry out the irrigation work of various plants.

Technical systems are necessary when transporting technical solutions.They have a full range of parameters of dielectric and mechanical resistance, chemical strength. Due to the fact that they serve to protect the lines, they are supplied without a probe. Similar products are made from industrial waste, from the model "PE" 23, 60 and 80, 100.

Water wells are equipped with casing PND means. They prevent natural decomposition and groundwater shifts.

DKC electrical pipes have the protective properties necessary to prevent negative effects on the electrical cable during wiring installation.

The range of products for conductive events is wide. These include pipes:

- hard;

- flexible;

- metal;

- polyethylene.

Flexible corrugated polyamide products DKC is used in cable schemes.

A few years ago, a polyamide corrugated flexible tube appeared on the market, which does not spread fire. It serves to protect against external physical impact and additional electrical insulation of wires and lines of industrial plants, transport, robotics, electric machines.

PND is a high-density material, which is characterized by excellent durability with respect to stretching and tearing.In addition, due to the elasticity and flexibility of it produce pressure pipelines.

Depending on the characteristics of the pipelines are:

- non-pressure - no requirements for permissible load, are systems for technical purposes;

- low pressure - maintain internal pressure up to 5-6 atmospheres;

- high pressure - have a wall up to 7 centimeters thick, resistant to pressure up to 16-20 atmospheres.

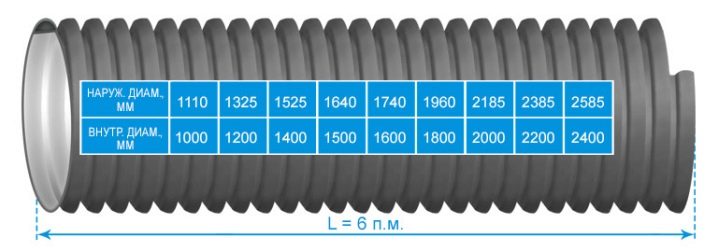

Dimensions

Speaking of variations in the size of this pipe product, the main ones are considered linear, which include the diameter, wall thickness, product length.

An important characteristic is the ratio of diameter to thickness. It determines the level of product strength. This definition is indicated by applying an SDR index. The value of the SDR indicator of the PND products is in the range from 6 to 40.

Thickness and length are measured by conventional methods. But the diameter can be of different sizes depending on the measurement system.

- External diameter - the calculation is carried out with the measurement of the circle constituting the plane of the front side of the pipe.

- Inner diameter - calculated by measuring the circumference of the inner layer. As a rule, it is smaller in size.The resulting difference of these indicators is twice the thickness.

- Nominal diameter - the value that can often be found in the technical description of the HDPE pipes. Under it imply a circle in contact with the fitting fitting.

- Nominal diameter - standard unit. State regulatory documentation in most cases includes this definition. It is considered rounding up the nominal definition.

The marking of most modern samples according to GOST is indicated on the surface. It indicates the exact size of the diameter in one of the measurement methods. The size of the products ranges from 10 to 1600 mm.

For the construction of water supply or irrigation systems, pipe products with a thickness of 16-25 mm are used. The use of a product with a larger diameter is not rational, since their main purpose is to provide a large number of consumers with liquid.

Gas lines require the use of products with a diameter of 20-25 mm. Sewage drains are mounted with laying of lines with a diameter of 110 mm. Smaller size may cause congestion during operation.

Products with a maximum outer diameter of 50 mm are used during the installation of systems using the butt method. Products with a diameter of 32 mm are used for laying plumbing for technical purposes.

Scope of application

The amazing properties of the cable made it possible to apply it in many areas of activity: durability, compliance with all sanitary and hygienic standards, resistance to destruction, and temperature changes.

They are used for laying systems in the construction industry, food, chemical industry, agriculture, when installing heating mains to waterproof pipes and other areas. Product flexibility makes it possible to use it for the construction of water supply and sewage systems.

Not so long ago, the corrugation of the HDPE began to be used for separate laying on combustible bases of electrical devices of various purposes: electrical, television, computer circuits.

By means of corrugated double-wall pipes for the wiring of electrical and cable systems, the installation process takes a little time.

Products are widely used in everyday life. So, it is ideal to do electrical wiring on the summer cottage in a wooden house.In addition, due to its protective properties, it can be stretched along the bottom, hiding it in the ground.

But remember that the use of plastic corrugated pipes for the safety of electrical wiring is prohibited, because after 12 months it will be subject to destruction.

Tips

The quality characteristics of the material from which the pipe products were made influence the service life. In some cases, the water supply line from the HDPE may function for several decades, but often a properly mounted system will leak in a year or more after installation.

The whole reason lies in the source material. For example, some companies use recycled materials to manufacture products. Moreover, production is carried out even from used disposable syringes. This product for durability and reliability will withstand any competition. Cold water from such pipes will give a sharp unpleasant chemical odor that does not disappear after a time.

Experts advise to consider the appearance of the HDPE pipe to determine the choice of quality products.

The product is of poor quality black or dark gray. There is no alphanumeric marking on the surface. With the naked eye you can see pieces of alien inclusions or stripes. The product emits a sharp chemical smell.

This product is used only for the installation of technical systems.

In order to carry out drinking water, the construction uses black-tone hoses with blue stripes or completely blue. A quality product is distinguished by a uniform painting, smoothness, without the presence of impurities and strips. The walls have a thickness that fully meets all the requirements of GOST. For high-quality products, it is necessary to apply by embossing or a printer the designation - “Drinking pipe GOST 18599-2001”.

Additionally, the following data is indicated on the surface:

- diameter;

- Wall thickness;

- information about the manufacturer;

- The strength level of the product is indicated as PE100 or PE80.

If you choose quality products, this is not enough. It is also necessary to correctly carry out the installation measures so that all the schemes are laid out in the necessary sequence.Provide a fully professional installation can only specialists.

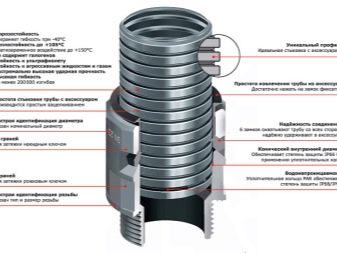

Most of the joints of plumbing connections are mounted using collet fittings that prevent leakage of connections.

To the note: due to the absence in the flow part of the compression fitting of metal elements, the corrosion resistance of the pipeline circuit made of this material increases.

For assembly activities stock up fittings. Joints are connected by means of adhesions, which can be done by one of two methods: into the socket and butt. In the case of strict observance of all the necessary recommendations for sealing, the junction will be distinguished by strength and a long period of validity. The collet or compression fitting is characterized by great convenience, however, its cost is higher.

The rubber ring, clamped with the nut, ensures the tightness of the fitting.

The process of fastening the fittings of HDPE products according to the principles of installation is similar to the fastening of metal-plastic. To tightly press the fitting, it is recommended to use a conventional gas wrench or spring-loaded.However, care must be taken with the tool in order not to damage the connecting structure.

To obtain a tight and hermetic scheme, you need to insert the tube into the fitting until the end. If a chamfer is required, it can be removed for easier pipe entry.

In case of incomplete insertion of the product, a tube may leak through a certain time period. Additional strength joint provide sealant.

The most expensive elements are electrically. At the edges they have installed a special heating spiral for sealing. They are able to withstand a voltage of up to 48 V. In most cases, they are marked with a barcode, which helps to know the voltage level and the time it takes for the sealing process.

During the installation of the water supply network of the pipe PND products, remember that in direct sunlight they are destroyed, so they should be in the shade.

When placing the aqueduct under the earth's surface, it is not mounted in straight rows, but winding. This requirement should be complied with due to the fact that the level of thermal expansion of the HDPE is sufficiently high, and if the installation was assembled in summer, then in cold time its size will decrease.

During the winter season, the temperature level of the liquid decreases, the tube length decreases in a similar way, stress will arise and the structure may rupture. To eliminate such mounting incidents, it is necessary to attract specialists.

Overview of corrugated PND-pipes of one of the Russian manufacturers, see below.