Pipe cutters for pipe: design features and rules of use

To ensure the tight connection to the pipes, as well as the durability and integrity of the structure as a whole, various products and materials are used in the work. Along with them, various devices and tools are used to prepare the elements of the system for installation. The category of such products should include faskosnimateli for pipes.

Device and purpose

High-quality welding of pipes in the system plays a huge role, since it affects the reliability of communications and the service life of the entire structure. Once you have completed the work with all requirements taken into account, you can reduce the risk of a pipeline or water supply system breaking through, the elimination of which will require serious expenses. However, for metal pipes whose diameter is more than 3 mm,Making a reliable connection is quite difficult, and products with a diameter of 530 mm or 20 mm are often used for various communications.

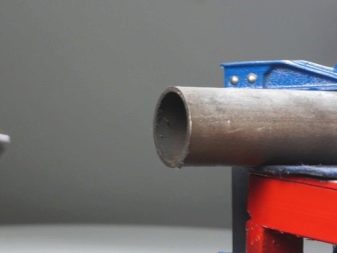

To solve this kind of problem, specialists use a special method for processing system elements.whether it be metal, plastic or other products. The essence of working with pipes is to use a stripping device that allows you to remove a bevel from an element. For these works, a face-cutting machine is used, or as it is also called a fascorez.

The purpose of such a tool is to chamfer the ends from the inside and outside of the pipes., so you can prepare the product for further work, removing any burrs that could occur after cutting or any other mechanical processing.

It is precisely the fascicators that represent the main tool for preparatory work with plastic, copper, steel, polypropylene, metal-plastic pipes, which are commonly used for arranging pipelines for various purposes, for example, water supply, sewerage,heating systems and all kinds of construction and installation work to provide residential and public buildings with mandatory communications

Almost all varieties of the edge-cutters carry out the processing of the product very quickly, in one pass through the width you can remove the intended edge layer and fully prepare the working base for the future weld. At the end of the pipe manipulations, its base becomes smooth, without various defects.

In addition, when choosing the method of connecting pipes with the help of fittings, a better tool for processing than a face picker is difficult to find. Chamfer preparation enables products to seal tightly and easily while retaining all internal seals that guarantee a good connection of the joints of the products.

Taking into account the design features of the tool, it is worth noting that it consists of a body, which, depending on the model, can be made of different materials, as well as a roller cutting mechanism, due to which chamfering is performed at an angle.

In addition, the instruments in their configuration have a number of auxiliary elements:

- specialized self-centering clamps;

- centralizer with interchangeable cams;

- micrometer screws and steel cutters;

- proceeding from a version - with the pneumatic drive or the electric drive.

The incisors are the main components of the fascorez, providing cutting edges.

Experts identify two main types of incisors used in the apparatus:

- the shaped elements intended for the internal, external and face bases which differ in difficult geometry;

- end elements - their scope of application consists in the maintenance of simple parts in shape.

Replaceable cutting components of the pipe cutters allow the device to chamfer from different angles:

- flat types of incisors handle the edge at an angle of 0 ° C;

- conical elements can work at an angle of 15 ° C, 30 ° C, 35 ° C, 37.5 ° C, 60 ° C;

- internal conical - 15 ° C.

Machines for the processing of metal products, a face picker for HDPE pipes, as well as products from other raw materials, have the opportunity to work with parts having different diameters and thicknesses. Devices that are used in the manufacturing sector often have the possibility of color marking, which eliminates the risk of operator errors when working with the device.

There are varieties of edging for pipes that have a shock-resistant protective sleeve, can simultaneously perform facing, calibration, chamfering and deburring on the products. In some cases, when maximum conformity with certain sizes is not required, countersinks are used as a face-lifter.

Advantages and disadvantages

In order for the work of the welder to be performed at a high level, besides qualified personnel, there is a need for high-quality and fully prepared material for work. In some cases, angle grinders are used for chamfering, however, this process takes a lot of time and is a labor-intensive measure.

That is why in the consumer and industrial areas, widescalers have become widespread, which have positively proven themselves in the performance of their tasks.

The demand for devices is due to their inherent advantages.

Among them are the following points:

- devices are easy to manage and perform tasks;

- most products are mobile and ergonomic;

- thanks to the work with facoskimyateli it becomes possible to trim and form a wide chamfer

- devices successfully cope with the processing of end parts of steel products, which are distinguished by large volumes;

- devices are characterized by high speed and adjustment settings - the type of chamfer side joints, the size and depth of cut;

- the ability to quickly perform the change plates with their own hands without the use of specialized tools;

- during operation, the devices do not emit a lot of noise;

- the devices do not release harmful substances into the environment, therefore they are completely safe for health and the environment;

- during the processing of products on the device, their chemical composition is fully preserved.

Among the minuses of the mechanized or manual hand patcher for pipes, it is worth noting the need in some cases to additionally process the edges of the products before further work.

Kinds

In today's market, manufacturers offer the consumer a large selection of such tools.Product classification is based on the purpose and type of material used.

- Receptacles for working with plastic pipes. Since plastic pipes are increasingly used for arranging various communications, replacing steel products with them, the installation and maintenance of plastic pipelines also requires the use of special devices. Due to the fact that the use of improvised means for flaring the edge can lead to deformation of the edge of the product, it is common to use such specialized tools for working with pipes that can prevent the sealant from deformation and reduce the risk of leakage in the pipeline during operation.

- Devices for working with pipes made of metal. Products are widely used in the construction and installation of various kinds of systems, as the pipe edge cutter for metal products has several features: small size, due to which it can be installed and used almost everywhere, low weight - about 20 kg, the ability to work with products that are large diameters.

- Apparatus for processing pipes made of polyethylene.Such a tool is located on the metalwork bench, the pipes are installed in the device and rotate in a certain direction. Thanks to the built-in cutter body, the burrs are removed on the products.

In addition, based on the complexity of the functions performed, the pipe face pickers are divided into several groups of devices.

- Devices of hydraulic type - most often used on an industrial scale. The task of the device is the machining of pipes before welding. It is quite simple to work with the device, the choice of width and chamfer angle is set in the machine settings.

- Pneumatic devices are remarkable devices with the ability to work without being tied to the presence of electricity and the risk of damaging the wire. In addition, often there are conditions in which it is necessary to perform processing of the edges of pipes in places where the use of electricity is prohibited, for example, in explosive areas of construction sites, in the oil, gas or chemical industry. In such cases, pneumatics will be an indispensable assistant. However, the disadvantages of the products include the need for additional equipment, most often in its role as a compressor.

- Electrical devices - the main advantage is the widespread use of electricity, so connecting the device to the power supply is not difficult. In the industrial field, such devices are used most often, since the edge cuts are characterized by high speed of work and excellent quality of the processed edge of the pipe. The device can operate in several modes, in addition, the blades in the device can be easily and quickly replaced. The downside of the unit is the need for strict observance of precautionary measures, since the operator may receive an electric shock during inaccurate handling of an electric-type face picker.

- Hand-edged cutters - these units have a minimum weight in comparison with the above listed varieties and small dimensions. They are used for chamfering in the holes, the tool copes with the task of processing straight and radius edges. In addition, manual edgers can be used to work not only with pipes, but also with sheet metal products. The devices are in demand for carrying out preparatory manipulations with pipes made of different types of raw materials, and the equipment of the manual edge-cutter allows you to perform a different cycle of tasks.The scope of the device is not limited only to the implementation of small-scale work in the household sphere, since the bevel picker has proven itself well in the process of operation at medium-sized construction sites.

Among the advantages of hand tools are the following features:

- ease of management - for work there is no need for special qualifications, the angle and width of the chamfer removed is very easy to adjust;

- low weight and size, thanks to which the device is characterized by mobility;

- during operation, the device consumes the minimum amount of electricity in comparison with the stationary phase pickups;

- there is no need to arrange a special place for installation and work with the device;

- For greater comfort of use, the manual-type models have special ergonomic handles with a rubberized coating, which reduce sliding and vibration during chamfering.

It is also worth noting some of the disadvantages of devices: the unit is not designed to work with large-sized products, which reduces the scope of its operation, manual edgers have a lower level of performance compared to stationary tools, it is necessary to fix the working part in the process of working with it,and the pipes should be further processed before their welding.

Criterias of choice

Manufacturers of pipe bezers for pipes offer their products in a large variety, so the question of searching for a device is not particularly relevant today. But the question of selecting a tool for work should be approached with all the responsibility, since the choice in favor of a product will depend not only on financial opportunities, but also on a number of important nuances.

Experts recommend to study in detail the range of products presented for the preparation of pipes for welding, basing their choice on the basis of criteria that will be individual in each case.

- The volume of work - in cases where small scale is planned, then there will be no sense in the acquisition of stationary and expensive tools. To solve such problems, you can limit yourself to a manual face picker, which will perfectly cope with edge processing in order to produce good adhesion when welding products.

- The required power and speed of work - hand-held and mobile machines have a lower performance indicator, however, based on the scale of the object, this parameter may be uncritical.For large-scale production low-power devices will not work.

- The type of material with which the work is coming - taking into account this criterion, the aggregates have their own classification, so the question is fundamental in the selection. If you plan to work with the metal, in particular, with steel elements, then the preference for the purchase should be given to more powerful devices.

- The range of available products - the model range, as well as the functionality of the pipe cutters for pipes are regularly updated and improved. Due to what products with new equipment and functionality are on sale. However, in the pursuit of the latest generation unit, it is important to note the expediency of acquiring a device with a ton of additional functions that may not be needed in the work, but their presence will significantly affect the cost of the phychostender for pipes.

Features of operation

When using electrical machines for chamfering, it should be borne in mind that the device must be grounded without fail. The power supply cable must be reliably protected from mechanical damage that may occur during the work with pipes.

Since most of the faskosnimateli has moving parts, in the course of the work it is necessary to observe safety precautions, since violation of the operating rules of the device and the procedure for working with it can lead to an accident.

Portable units are set and fixed on the base with the help of cams and flywheel, after which it is aligned on the workpiece. Special cutters are selected for operation based on the required machining angle. With the help of rotation of the flywheel, the cutters are located in the desired position relative to the element. Then the cutters are manually divorced, the device is turned off and removed from the product.

There are models of universal pipe cutter for working with products that have a small diameter. They are mobile and very convenient in work. They can easily cut the chamfer from pipes made from different types of raw materials in accordance with GOST. To accomplish the task, it is enough to fix the pipe in the caliper of the apparatus, manually bring the cutting inserts and start working with the device in the cutting mode.

Edge cutters are quite unpretentious in maintenance. The main part of the mechanism that is most susceptible to wear is the milling cutter with cutting inserts,the service life of which varies depending on the model and type of material used to manufacture the part.

See below for a review of the portable pipe cutter.