Reinforced concrete pipes: how to choose and install?

Reinforced concrete pipes are manufactured using the latest technology. They are perfectly used in private construction and have long been a full-fledged replacement for plastic pipes and, moreover, cast-iron analogs. The use of reinforced concrete structures makes it possible to save substantial funds and greatly reduce the actual cost of erection of various buildings. In this article we will discuss how to choose reinforced concrete pipes and how to install them yourself.

Special features

Reinforced concrete pipes are successfully used in various areas of civil engineering, as well as in the construction of communication networks of various types.

It should be said that most often they are used to create:

- sewage for domestic and industrial wastes, and if we talk about options of a larger diameter, they are used when laying the main type of collectors;

- storm sewer networks;

- highways for pumping liquids that are non-aggressive in their chemical composition;

- drainage through road mounds.

Rectangular and round reinforced concrete pipes are used as structural components for the construction of various structures.

If we talk about the benefits of such products, then the following should be mentioned:

- have minimal susceptibility to corrosion;

- perfectly resist overgrowth, because they are durable and inert, and rough internal walls do not affect liquids pumped through pipes;

- good resistance to physical impact;

- impermeable to liquids;

- resistant to biological and chemical substances;

- have high strength;

- produced in serial ways with different performance characteristics;

- have a low cost.

In addition to the advantages, there are also disadvantages:

- large mass;

- corrosion is not excluded, which causes leaching of concrete, growth and thinning of the walls.

For the production of such pipes can use one of the ways:

- vibropressing;

- centrifugation.

Heavy concrete is always made very strong and stable, and this will be extremely important in compression and tension. In addition, it is not subject to the influence of low temperatures, is completely impenetrable, and when it is created, high-strength steel reinforcement is reinforced. Although sometimes these pipes are reinforced with wire.

These reinforced concrete products are a monolithic structure in a frozen state. More often for the production of pipes is used all the same vibropressing. The reason is that such products will be stronger and more qualitative than their counterparts, made by centrifugation. In addition, the latter have a more rough and rough surface, because of which their strength will be lower.

In private construction they are used in the following areas:

- the construction of various structures and buildings;

- infrastructure arrangement of the site;

- laying of collectors, drainage and various communications;

- construction of common as well as storm sewer networks.

It should be said that the types of pipes under consideration are used for laying domestic and storm sewers, where water is not aggressive to the material.

The aggressiveness of the fluid that is transported is normalized by the requirements of SNiP.

Depending on this indicator fluids are:

- mildly aggressive;

- medium aggressive;

- extremely aggressive;

- non-aggressive.

If it is necessary to transport liquids whose aggressiveness is high, then according to the standards, the concrete must have protection made with the help of anti-corrosion agents, which is rarely practiced even by manufacturers. This is due to the fact that anti-corrosion treatment with a good tool of the appropriate category can significantly increase the cost of reinforced concrete products, and their use may simply become unprofitable from a financial point of view. But at the same time, the lack of anti-corrosion treatment affects the service life of such pipes: through time, through-gaps appear in them, and growths appear inside. And the cost of their restoration and even more so the replacement will be high.

Kinds

When selecting reinforced concrete structures for the needs of conventional construction, it is necessary to know that there is a whole classification of such pipes.

By operational features, they are divided into:

- free-flow;

- pressure head.

ZhB free-flow are usually used for transportation of various kinds of liquids by gravity flow. The material from which they are made cannot be used in cases when the working fluid is poured inwards under high pressure. These types of pipes can take serious loads, but only those that have stability. It should be said that some models of this category can withstand a serious load from filling the ground: a number of pipes can withstand backfilling up to 6 meters from the upper boundary, the second group - up to four, and the third - up to two. True, there are in nature the fourth and fifth groups. The chimney of a large diameter of the fifth group can withstand the twelve-meter height of the backfill, and the industrial fourth group can withstand the eight-meter height of the backfill.

At the same time, the pressure pipe is used to transport precisely liquids under pressure: it is characterized by increased strength and, in contrast to the first category, has thicker walls. Usually its thickness is somewhere ten percent more than that of non-pressure.

If the criterion is the method of connection, then there are:

- bell-shaped;

- faltsevy pipes.

In the first there are special seals that provide sealing. The products are easy to install, and this is the most common type of pipe used in private construction.

They have several distinctive features.

- Installation is made tilted. The required slope in this case is 1–2 degrees.

- The material is made according to one of the two aforementioned methods, and the form of creation consists of two elements - external and internal. Outdoor is made of two half-form, connected with bolts on both sides. By the way, in nature there are no rectangular and round pipes of this type.

The seam type has selected quarters along the edges, which allows joining elements. In this case, a mixture of cement and sand is used as a seal. Both types of products can be made non-pressure or pressure. The advantage of such products is that they have the same diameter throughout the line. At the socket diameter of the joints will be above the cross section of the main part of the pipe.

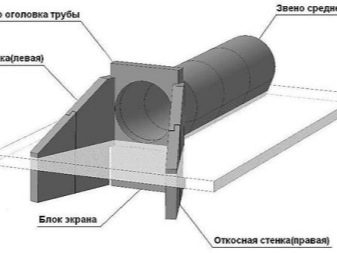

There are also culverts and pipes that have a flat sole.

There are four groups depending on the pressure that they withstand:

- 5 atmospheres;

- 10;

- 15;

- 20.

As a rule, they are used to transport non-corrosive liquids to concrete, if their temperature does not exceed 40 degrees. As a rule, we are talking about socket products with an internal diameter of 40 centimeters to 1.6 meters.

They are usually used for laying sewer and waste type pipelines. Unlike steel models, concrete products resist corrosion and can maintain a smooth surface inside for a long period of time, are dielectric and contain a small amount of metal, which significantly reduces the cost of production during long-term operation.

Installation

The installation of reinforced concrete pipes begins with the delivery of products to the place of laying and unfolding products along the trench pit. Given their great weight, there is a need to use different special equipment. Now follows their submission directly to the place of laying. Also delivery is carried out by means of railway transport to the place where they will be.

Before laying the reinforced concrete pipe, it is necessary to create an emphasis of the concrete type in order to ensure a stable position for the initial pipes when they join.

Before installing on the smooth end of the product, the distance is measured, how long the pipe will be wound into the socket of the pipeline already laid up to this part. When lowering into a trench with the help of cranes, reinforced concrete products are laid on the foundation that has already been made. At the end of the sleeve is mounted a ring of rubber, after which the pipe is inserted into the bell is already mounted. It remains only to verify the installation.

After laying the reinforced concrete pipe, the joints are sealed. Pipe connections, where there is no rubber ring, are sealed with a bituminous or hemp cord with resin mixed with asbestos cement. In the same way, so-called sealants-mastics are used, which provide excellent water resistance, joint strength and elasticity. Fold pipes are sealed with mortar based on cement and sand, rubber-bitumen gaskets, as well as asphalt mastic and other materials. As an antifreeze additive for mixtures that are used for sealing joints of compounds, sodium chloride, sewed, calcium chloride or sodium nitrite are used.

The made area, which has not yet been filled, should be subjected to preliminary tests. If the diameter of the pipe is quite large, then it is necessary to test only a butt cap. After all stages of installation are completed, backfilling of this section of the pipeline is carried out. Then you should conduct the final test.

The installation of the reinforced concrete pipeline is carried out using a special crane of the rifle type, which is placed in the middle of the pipe to be laid. The pipe is grabbed with the help of lines and is fed forward by the sockets in the process of forming the pipeline. Also in this case, one rule should be observed - it is necessary to supply pipes against the flow of liquid.

Manufacturers

Today, the market can be found mainly products of domestic enterprises. In Russia, the production of such pipes is carried out by a large number of companies, including Ineltek, Stroyinvest and Modern Concrete Technologies.

The Ineltek company manufactures reinforced concrete pipes.

If we talk about the company's products, then this plant produces:

- reinforced concrete pipes;

- microtunnel pipes;

- pipes are free-flow bell-shaped;

- links for reinforced concrete pipes and so on.

If we talk about the company Stroyinvest, then it has its own production of reinforced concrete pipes. Since 1992, the company has been manufacturing reinforced concrete products. First of all, we are talking about reinforced concrete pipes. The company also produces links for culverts of various types and sizes, as well as various components for them.

The company occupies one of the leading positions in this market in the segment of road and bridge construction, as well as the construction of energy facilities, where various reinforced concrete structures are also actively used.

The company "Modern Concrete Technologies" has been producing reinforced concrete pipes and related products for more than one year. During this time, the company managed to make significant progress in the matter of creating and selling the types of pipes in question. Here, they are all produced according to the most modern production method - vibropressing, which allows the company to produce large quantities of goods with excellent quality indicators, while at the same time not raising the cost of products too much.

In the manufacturing process, high-quality foreign equipment is used, which enables the company to even sell its products to other countries, for example, to Germany and France. The company can carry out uninterrupted production of high-quality reinforced concrete pipes.

In general, as you can see, in the domestic market you can find high-quality and sought-after products of this type, made in accordance with GOST, as well as all European standards. At the same time, their price is not so high, which makes it possible to ensure an excellent ratio in terms of “price-quality” indicators.

Tips

It should be said that the reliability of products that are laid in the ground, should be determined by their strength and deformative characteristics. For this reason, when choosing a product, you should know in advance what loads the pipe types will have to withstand.

If you look at the deformability index, the reinforced concrete pipe is a rigid structure, which is extremely rarely deformed under the influence of external operating loads.

To ensure reliable operation of a pipeline made of reinforced concrete pipes, the following points should be considered:

- inspect the trenching carefully;

- it is necessary to work out butt joints with high quality;

- coupling of reinforced concrete pipes should be carried out using caulked hemp or a sealant with cement-sand mortar sealing, which should ensure impermeability for the entire period of operation;

- rubber rings should be used to seal the joints;

- it is required to take into account possible subsidence of soils.

Another tip - be sure to take various measures to prevent ground movement. Despite their strength, even reinforced concrete pipes cannot resist the movement of soils, and such pipelines can fail very quickly with this phenomenon.

Also when choosing is extremely important such a thing as marking. For some reason, many people ignore it, which then causes problems.

But we advise you to pay attention to this moment, so that the pipes maximally fulfill the function that is necessary.

- The letter T means that the pipes have only a cylindrical shape.

- TB and TBP are varieties of cylindrical type pipes. They are very similar in their characteristics, but the second type will be better, since it has a special sole, which must be taken into account in such a process as microtunneling.

- The literal values of TSP and TS say that such pipes have connecting links in the form of steps. Model TSP in contrast to the vehicle simply has a special platform.

- Models with letter meanings TO and DFT are varieties of flanged products that have special seals at their joints. Such pipes can be used as road pipes.

Thanks to the reading of such markings, you will be able to accurately determine the type of pipes you need, which will serve you for a long time and will perform its function qualitatively.

It is also necessary to pay close attention to the choice of cage for such structures.

As you can be sure, to choose reinforced concrete pipes is quite simple., if you know what exactly you need them for and how they will be used. And if we talk about their installation, it is impossible without the involvement of special equipment. But if you follow the instructions written above, even a person who previously had nothing to do with the laying of pipes will be able to do it.

See how the concrete pipes are made in the video below.