Choosing Stainless Steel Corrugated Pipe Fittings

One of the important conditions for the implementation of high-quality installation of plumbing, heating and other systems based on corrugated stainless pipes is the reliability and complete sealing of their connections. Making the strongest joints when joining cause various elements called fittings.

Features and Purpose

Fittings are special fittings for installation. Without them, it is almost impossible to manage both a qualified specialist in the installation of corrugated pipe systems and a beginner. They are also called elements of connecting reinforcement.

These parts perform various functions:

- ensuring the tightness of mutual transition of two branches of pipes;

- making a solid butt joint of pipes of different thickness;

- the ability to regulate, stop, change the flow of fluid in the structure;

- improvement of the existing system;

- change any part of the previously installed system (for example, a box);

- execution of branches from the main circuit of the system.

Despite the diversity of the range, all fittings are divided into two main types.

- Seamless options. These are the one-piece fittings with the highest strength. However, it should be borne in mind that when assembling them, special tools (in particular, crimping pliers) may be required.

- Electrofusion fitting. This type is made of a number of parts, as closely as possible selected to each other, thereby achieving the smallest gap.

Mount rules are generally available for study and are not particularly complicated. The presence of a decent range of fittings for stainless corrugated pipes makes it possible to install the system personally at home. With proper observance of the technology of connecting joints, you will have a high-quality and durable system.

Currently, firms engaged in the production of stainless corrugated pipes, do not particularly want to establish a serial production of fittings for their own products. The increasing turnover of goods provides manufacturers with a good and constant profit. Fittings are produced by other companies.

The market presents products of this category from different countries. The most popular products of Western European companies. Russian manufacturers are also increasing their production volumes, while tightening the check on the quality properties of the goods produced.

For gas supply and fluid systems, elements of various types are used., therefore, the choice should be especially attentive. It is also important to take into account that in the absence or uneven installation of a sealing gasket, leakage and disturbance in the functioning of the future system may subsequently occur.

Before performing installation work, professionals advise to make a layout of fittings in accordance with the plan-project. It is also necessary to thoroughly check the parts for defects, chips, scratches, cracks and other defects.Particular attention should be paid to the correct size of parts (1/2, 3/4 inch, etc.).

Kinds

Prior to the commencement of work, make a plan and estimate the project At this stage, it is worth making the right choice of optimally suitable fittings for stainless corrugations, considering all the important nuances. The use of brass, plastic and steel connecting elements is possible. The optimally selected type of connector allows you to easily install a system of any complexity.

From metal alloys

Particularly popular and practical fittings made of metals. They are made of stainless steel, where the presence of chromium can reach 16-20%. Also often, fittings for metal pipes are made from brass.

Distinctive advantages of such parts:

- not susceptible to oxidation at high humidity;

- insensitive to external factors;

- well suited to use even where possible temperature changes, including strong freezing;

- resistant to hydraulic shocks.

To connect the stainless corrugation with a pipe of a different material (for example, from a polymer), brass fittings are chosen. Brass fittings are installed using crimp rings as well as threaded connections.The threaded part makes a strong connection, but the thread must be tightened. For better quality of work, crimping pliers or a set of tightening keys are used, which are matched to the size of the pipes. Reliability and safety of crimping elements do not lag behind that of steel connectors.

Today, brass and steel connecting parts from popular brands that produce heating equipment have become very popular. When using low-cost and low-quality fittings, sooner or later, an emergency situation is guaranteed to occur during the operation of the system. It will smoothly carry out its functions only to a place with a poorly chosen fitting. Therefore, to avoid leakage of liquid or gas is unlikely to succeed.

Plastic connectors

Such parts are used as connecting elements in combined systems, as well as for connection to the central water supply system. With their help, you can easily connect a polypropylene pipe and stainless corrugation.

The key characteristics of this type of fitting are corrosion resistance. and stability at high pressure surges inside the system. It should also be noted that installing plastic fittings, you can not strongly tighten the nut, otherwise it may burst.

Names of parts

Practical and easy to install fittings are designed to perform a variety of tasks. It also causes their rather wide application in designs of systems.

Allocate crimp and press fittings. The crimp fittings connect the tubes with the assistance of a clamping ring and a cap nut. Press fittings are made without threading, and their installation is impossible without a pressing tool.

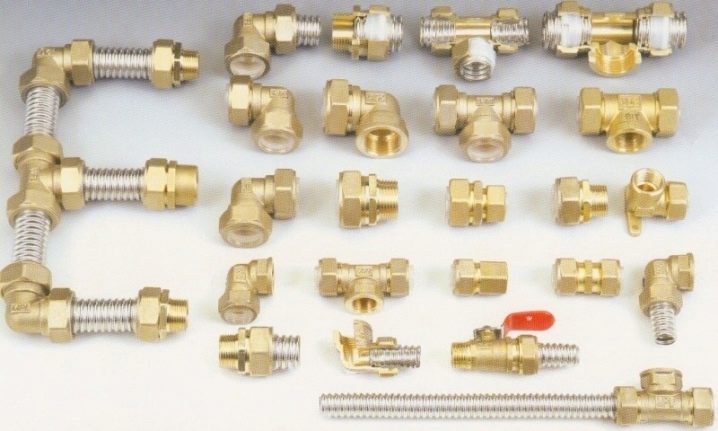

According to their operational purpose, the fittings are sorted into several groups.

- Coupling. This is the most popular type of parts that connects pipes in a straight direction.

- Turning angle It is used to change the trajectory of the direction of the pipeline system. Despite the fact that pipes of this type, with their flexibility, easily take the necessary shape, it is not recommended to bend them with a radius exceeding two pipe diameters. Therefore, connectors come to the rescue.

- Tee.This detail helps to change the direction of the flow from the main circuit.

- Cross. It is used to perform multiple branches of the main thread.

- Technical plug. It provides a complete overlap of the system or its parts. The use of this part is possible only during the repair and adjustment activities.

- Adapter. Its use allows splicing pipes of different diameters. This is the most rational type of connecting elements.

Tools for installation and repair work

For installation, a set of special tools is needed for trimming the corrugations and fixing the joints. None of the installer is not without these devices.

The kit includes:

- special pipe cutters (with their help it is possible to trim a corrugated pipe while preserving its shape and forming the most precise cut);

- device for pressing fittings;

- long keys and crimping tool;

- device for flaring the edges of the corrugations.

A good specialist should have on hand and often the required apparatus for making welding joints.It can be useful in situations where the use of a crimp fitting is not possible.

Connection order

First you need to measure the intended distance, then cut off part of the product with a pipe cutter. Then you should carefully give the corrugation the desired shape. The nut of the connecting fitting must be loosened on the side of the intended fastening. Then you need to tightly insert the pipe into the fitting, tighten the nut using the wrench. Silicone when squeezing is squeezed and retracts into the pipe fins. If you follow these rules, you will succeed.

When assembling structures by the type of warm floors on the basis of stainless corrugated pipes, any craftsman needs to know one nuance. The use of a fitting for corrugations made of stainless steel according to the type of coupling connection of the system when laying on the floor is impossible.

Because of this, unwanted leakage can occur already during commissioning. It is also important to use only whole pipes without unnecessary connections.

Any consumer at least once in his life faced the problem of a breakdown or accident in the water supply or heating system at home.However, everyone should know that the installation, repair and maintenance work in the systems of heating and plumbing should be performed only by a highly qualified master. And when repairing gas supply systems, finding a specialist is a particularly important condition.

Possible faults after installation

It happens that after installation the connection gives a leak. In this case, shut off the main valve and tighten the nut with a wrench. If the leakage persists, re-disassembly of the connection is necessary. It is necessary to check whether the corrugated tube is evenly cut, whether it is deep enough to be inserted. There are also cases when installers forget about seals.

If, with the help of all these procedures, the leakage of the fluid could not be eliminated, the fitting must be removed again, trim the pipe a little more and assemble the mount. If this does not help, it means that you got a defective fitting, you need to replace it.

Conclusion

Summing up, it can be noted that the fittings of various manufacturers have differences in configuration, however, the principle of operation of the parts is the same, and they are also made of the same type of materials.Installation of any circuit requires special attention. But an important role is played by the choice of materials. Steel and brass fittings are particularly reliable and practical. To date, they are the most suitable options for corrugated stainless steel compounds.

Buying fittings, it is better not to save. Of course, the cost of quality products is large enough, but they guarantee the smooth operation of the system for a long time.

You will learn more about installing fittings for corrugated pipes in the following video.