How to select and install a pipe plug?

A modern house is unthinkable without communications. Pipes - one of the most common types. At present, they carry not only communicative functions, but also decorative, design load. For this reason, the question of how to select and install a pipe plug is currently very relevant.

Special features

Plugs on pipes can seem, at first glance, a simple and understandable subject. It would seem that there is nothing easier than screwing a terminal nut onto the ductwork. However, the reality is not at all like that. All existing fittings today have a number of features.

These simple elements differ by several characteristics. It is important to remember that even their appointment may differ. Not every terminal element is created to tightly "turn off" the highway. In principle, technological, protective and decorative fittings are now distinguished.

Technological are those that are necessary parts of the construction of a pipeline. Their main task is to jam pipelines. Usually, this variation of the line detail is used during the elimination of accidents, according to technical and technological requirements, or with the aim of closing openings in communications.

Protective options are designed to preserve the integrity of the ends of the transported pipes and threads. They are worn on the ends of the transported material before loading.

Decorative variations must first carry an aesthetic function. They are chosen on the basis of the ideas of the general interior and the design project of the room.

The specified type of division is very conditional. In fact, there are several established standards for these communications details.

Kinds

Artificial jams for communications are used for different purposes.Based on the goals, they form the structure and determine the material of one or another element. These two criteria - material and purpose - underlie the widespread classification of end elements of pipe communication systems. Executable tasks appear in this description as the first criterion for dividing the types of pipeline sections under discussion. By appointment, there are two types of "traffic jams", described below:

- Shipping plugs. Usually made from plastic and used to transport pipe elements and protect them from damage.

- End caps. Designed to isolate the unused part of communications, protecting it from debris and other objects.

In terms of appearance and production technology, silencing elements are further divided into four types.

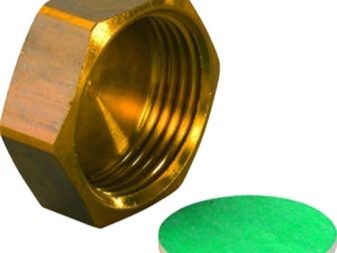

- Threaded plugs. Type of "constipation", which is installed on domestic water and gas networks. In their manufacture using different metals. However, all of them are equipped with internal or external thread. The most running parts are considered small parts. At their installation it is necessary to use sealant.

- Spherical zaglushins. Option that is used for critical networks (for example, gas pipeline or oil pipeline). They are well tolerated by various climatic influences and high pressure. Outwardly, such variations are similar to a metal sphere cut in the middle.

- Flanged plugs. The look is very similar to the cover. They are bolted to the pipe flange. To seal the connection using special gaskets. The type of gasket is selected based on the conditions: temperature and pressure in the line.

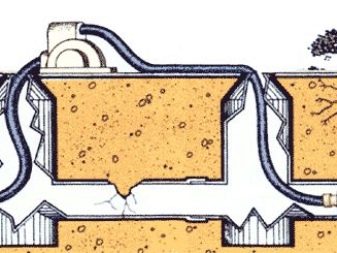

- Pneumatic rubber "blockage". This modern variation is used to isolate a specific section of a highway. They are inserted into the pipe and in a certain place are filled with air. The whole importance of the idea lies in the fact that in order to carry out repair work on a certain section there is no need to completely decommission the entire existing pipeline. They are very easy to dismantle.

According to the installation method, the stoppers are of two types:

- internal;

- outdoor.

Internal parts, such as plastic, are installed inside the HDPE pipe. If necessary, they are fixed with special notches. This mount inspires confidence.Outside, if necessary, everything is closed with a special lid. From above you can lay a laminate.

External "plug" is installed outside the communication unit. The pneumatic plugs can be round or rectangular, as well as stainless, iron materials and cast iron variations. Inflatable plugs are rarely used. It is set to a greater extent for performing “outdoor” tasks. This includes the protection of the construction site from the ingress of external debris inside. But it can also be aimed at closing the end part of the system element.

Large-diameter plumbing plugs can be mounted with an argon and blower apparatus.

Materials

Modern industry offers the buyer a huge selection of forms and materials. This applies to both the pipes and the plugs connecting them. As for the fittings for the communication system, the following options are distinguished from them.

Metal and chrome plugs

Pipeline fittings from this material are currently used very widely. With their help, plumbing and gas systems are made of iron and steel. They are ideal for industry.A significant disadvantage of damping elements of metal systems is their sensitivity to corrosion and rust.

With external influences, metal plugs with a chrome coating do a good job. It not only protects the main structure from external influences, but also performs a decorative function. Such elements of the pipeline give gloss and genuine beauty to all structures. Sometimes such constructive parts of communications become the center of the entire interior. The only disadvantage of this option is the rather high cost.

Pipes save rust from variations of brass. A significant disadvantage of this option is the very high cost and complexity of the production procedure. They are being replaced by modern analogues.

Plastic and plastic caps

Inexpensive “plugs” of plastic materials are characterized by high resistance to rust and corrosion. However, they are afraid of sunlight and high temperatures. For this reason, plastic systems are used exclusively for interior work. And also they are well suited for the role of "covers" for the fence. Only here for the sewer they will not fit.

Rubber "traffic jams"

There is a rubber version of the "jammers". They are unable to securely fasten any design. The reason is plasticity of the material. However, rubber products protect pipelines from debris and dirt.

Dimensions

Dimensions also act as a sign by which the ranking of jamming elements is carried out. Their range is quite diverse. However, all of them conditionally can still be divided into standard and non-standard options.

To purchase a standard version you need to know the length, width, section. And it is also necessary to specify the parameters of the pipe wall.

In a situation where standard “jammers” do not fit, you can choose a variant with non-standard parameters.

Installation

Welding plugs around the pipe can be done by hand, given all our recommendations.

The most reliable installation option is still considered welding. In this case, you can brew any part of the highway. Correctly made works guarantee reliable sealing of the pipeline for centuries. This option is not suitable for those cases when it is necessary to periodically dismantle.

Muting a communication system with a threaded element is considered one of the easiest ways. To do this, you need to properly tighten the fitting. However, you should not forget about insulating materials, thanks to which the screw connection will be a reliable unit.

Flanged fittings are installed using a sealing gasket and several bolts. The gasket must comply with the requirements for temperature limits, meet the requirements for pressure in the system.

Installation of the pneumatic version is made in several steps. First, the liquid is removed from the desired area. After that, a hole is cut to the size of the plug. The prepared fitting is inserted into the received opening and is injected with air. Everything is ready, the system is closed.

The installation options for special artificial “jams” depend on whether there is pressure in the system of the pipeline. In a situation when there is no pressure in the system, the “jammer” performs the function of sealing. To a greater extent this is the task of fixing the butt.

If there is pressure in the pipeline, then the situation changes radically. "Traffic jams" should have high durability.As the installation using welding or thread. For options of polyvinyl chloride can be used special glue.

It is worth noting that after carrying out these works, simply removing the "cover" will not work. In most cases, it will have to be cut off.

Tips

If you choose the perfect stub yourself does not work, then you can seek advice from experienced people. They are likely to advise to decide on several selection criteria.

The first step is to determine the operation of structures. Absolute tightness must be provided for the gas structure. Otherwise, everything can end sadly. The same can happen with hot water. For this reason, it is preferable to use special welding.

You can use and threaded options. However, they need to be mounted correctly.

Next, you need to define the tasks of this constructive area. If they have to cut off part of the pipeline at a time, then it is best to use flanges and pneumatic plugs. For long-term isolation of system elements it is necessary to use metal with threaded.If the silencing element is necessary solely for decorative purposes, then there are no restrictions on the choice. In this case, you should rely only on your own wishes.

And you should also determine the material of the existing parts of the system. The material of the plugs and other connecting parts must fully comply with the material of the existing structures. And this requirement can be considered the most important selection criterion.

The principle when choosing a "muffler" on the site is the idea that the plug must meet the parameters of the existing pipe.

If we talk about any specific advice, then there are a few rules. These very rules must be remembered by absolutely all people. They are very important and not negotiable.

So, for plumbing with hot water and heating can not use plastic and rubber "tubes". Otherwise, they may be damaged by high temperatures. This may damage the pipeline.

Pneumatic and screwed locks cannot be used on gas lines. They will not bring the necessary tightness. This will naturally lead to a gas leak, which is very, very dangerous.

If it is necessary to shut off a trunk of any type for a long time, use flange-type jammers.

The shape of the fitting and the shape of the pipe for which it is intended must necessarily coincide.

It should be remembered that for well systems there are specially created "plugs". They protect water from pollution.

In a situation when it is necessary to find a suitable "cover" for the pipes of the fence, it makes sense to pay attention to steel products. Plastic analogues are also suitable, but will not last long.

These simple tips will help to avoid unforeseen consequences and will make safe and easy operation of the pipeline.

For information on how to install the cap on the water pipe, see the following video.