Copper pipe soldering: technological features and progress

If steel is usually boiled, then copper is better to solder. Even a beginner can cope with copper soldering if desired, which is not the case with welding. Soldering at low temperatures does not spoil the structure and practically does not affect the properties of the metal, it is also not necessary to purchase expensive equipment that is usually difficult to find. Most importantly, solder joints are reliable and heat-resistant, which is good for heating. If you want, you can build your own water supply system, which will last for many years.

Types of copper pipes

Copper tubes can be annealed and unannealed.

- Annealed the pipes are again heated to 700 degrees, which is what gives them back elasticity. This type of pipe is more expensive than unannealed. Among the disadvantages are their fragility, due to the heating of the pipe wall becomes thinner.

- Unopened Copper pipes are strong and far from brittle, but they cannot be called flexible. When distributing such pipes are cut into small pieces and used only in conjunction with fittings.

Technology

The process achieves sealing the surface between the pipe and the sleeve through solder (a thermoplastic substance). Solder becomes more liquid at high temperatures and fills the space between the sleeve and the pipe, thereby connecting them.

For such works masters use a portable post for welding. It consists of gas cylinders, gearboxes, connecting hoses, a burner and a cutter. Welding posts are needed for work related to cutting, soldering, metal construction. Usually it is necessary for high-temperature soldering, because high-temperature soldering requires special equipment, including a portable post. However, if there is a desire to learn the soldering and to do the repair work yourself, then such a post must be purchased.

In addition, for self-soldering, you must familiarize yourself with GOST 19249-73 “Soldered joints. Basic types and parameters.The standard establishes the mandatory norms of each type of product, explains abbreviations, classifies compounds.

Materials and tools

Soldering of copper pipes requires special tools and materials.

- Soldering torch. The main tool, without which it can not do. It is better to choose a gas-welding machine with flame adjustment. Often used propane gas burner, usually it has a mode of saving gas and its supply. The flame is soft and does not burn copper. Acetylene oxygen burners can be distinguished, they safely and firmly solder parts. Acetylene-oxygen burners are either disposable with a balloon. The burner can be portable or stationary. In some cases, you can use a soldering iron.

- Solder for soldering copper pipes. When soldering, you can use either high temperatures (soldering is called high-temperature) or relatively low (soldering is called low-temperature).

There are hard and soft solders.

- Low-temperature solders with a melting point of less than 300 ° C. The tensile strength of them is 16-100 MPa. Such solders allow you to perform work at a temperature that almost does not affect the characteristics of copper. Practice shows that it gives less durable seams.Low-temperature use for water supply and heating. Everyone knows that lead adversely affects human health, so lead-free solders exist. They are used in the construction of drinking water pipeline. Lead-free solder, for the most part, consists of tin, the rest is impurities. Such material is expensive.

- Solders for high-temperature soldering have a melting point above 300C and tensile strength of 100-500 MPa. As well as the density of the seam, resistance to high temperatures. But a lot of experience is required, but for beginners there are frequent burns of copper, this metal is easy to burn. Flux solders are good because flux is present in their composition and on the surface. The use of additional flux is not necessary even for complex structures.

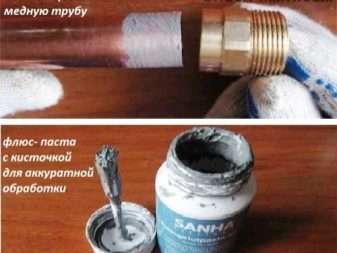

- Flux. This pasty substance is applied to the surface of the pipe and fitting. The paste protects against copper oxidation. Preference should be given to formulations where zinc chloride is present. There are many options for flux, it can be in a bottle with a brush, but experts recommend to buy material in the form of paste.

- Truborez. A tool for cutting copper pipes, one of the main devices. All pipe cutters have a similar construction and do not differ much. Pipe cutters differ from each other in design, longer handles at the device make it possible to use less effort.

Compact pipe cutters are suitable for pipes that need to be repaired, and they are already built into the design, but coping with small pipe cutters is much more difficult.

- Pipe expander A tool for increasing the diameter of the pipe, installing one design in another.

- Quick cutter (edge cutter). Accessory needed for surface stripping and chamfering.

- Fitting. Fittings with different uses and sizes.

- Thermal paste. Use the paste to heat the pipes. Contact and seam coat with thermal grease.

- Heat transfer pastes. They provide reliable protection of connections against desoldering, prevent material from changing color during operation.

- Brushes and brushes. Brush and brush cleaned excess flux in the course of work, clean the connection.

- Pipe tongs. For safety reasons, hot, red-hot pipes can be taken only with forceps.

- Protective gloves. When soldered, the metal melts, which in any careless movement will leave a burn on your skin. Fluxes leave chemical burns.

Ways

There are two technologies for soldering copper pipes.

- Low temperature (soft solder is used) is used in plumbing or heating systems. The environment where this technology is applied must have a temperature not higher than 110 degrees.

- High temperature soldering (hard solder) is used in systems with high temperature and high pressure. Used primarily in industry.

Which of the two ways to choose is your own business. But for high-temperature soldering you need a professional burner, which is not so easy to find in the store, and it costs a lot of money. At low-temperature use of a blowtorch or an inexpensive manual torch with a replaceable balloon is allowed.

Soldering pipes under nitrogen

Nitrogen treatment is needed for installation, and brazing of copper pipes without nitrogen gas is unacceptable. Often, structures are soldered with hard solder, which makes it possible not to worry about whether the connection will withstand high temperatures.During the brazing process, copper is heated to the red color of the metal, which has a negative effect on the structure of the material itself. Dross forms on the inside and outside of the pipe. Dross - remnants of burnt copper, which were formed during its heating. The walls of the pipes are becoming much thinner.

Nitrogen prevents the thinning of copper from the inside, and the use of solder prevents the destruction of copper from the outside. Soldering pipes under nitrogen will significantly increase the service life of the system.

If you decide to use nitrogen, then adhere to the following recommendations in the work:

- connect the line with a cylinder that contains nitrogen;

- then install the gas regulator or rotameter;

- Adjust the nitrogen cylinder reducer to the minimum nitrogen pressure, the rotameter is set at a speed of 5 m / min;

- as soon as the soldering is finished, nitrogen is allowed through the pipe, this is done until the pipe is completely cooled.

Soldering pipe building hairdryer

It is possible to solder pipes with a building dryer if the diameter of the pipe is small. Manipulations with this method are similar to the use of a burner. Using such a joint, the seams are very durable and withstand high temperatures. For beginners, when using this method, copper burns are inevitable.It is easy to overheat the metal, because of this there is a rupture of the material.

Capillary soldering

If the pipes have different diameters (the difference is not more than 0.5 mm), use the method of capillary soldering. Spike fills the space between the tubes. It should be noted that as such, the seam does not work, a seamless connection. Then use hard solders, their protective functions are better.

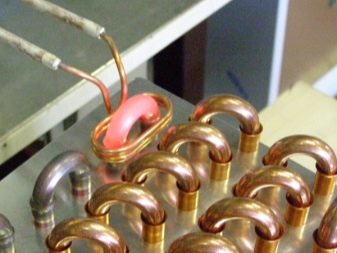

Induction brazing

High frequency current can have a beneficial effect on the metal. Induction rations became widespread because of their uniqueness, work by this method is carried out quickly, and the material does not become thinner, but retains its qualities.

The following advantages were revealed:

- Heat is generated in the pipe without interference from the outside;

- All equipment is automated, devices help to get the desired result with specific parameters;

- Induction brazing is carried out in vacuum, the metal in this environment is protected from corrosion;

- Saving production resources;

- Safety - when induction brazing does not need a flame or gas, only the seam is heated specifically.

Preliminary preparation

Before soldering copper pipes, you must prepare them.

Surface cleaning

The quality of the solder bond depends on the degree of cleansing of the surfaces being soldered. Any residues of any other substances that prevent the penetration of solder to solder, reduce its fluidity. All this leads to the fact that the substance is not distributed evenly, the surface is not completely processed by solder. Often, because of this, it is not possible to achieve high-quality work, and the connection fails.

There are two ways to clean the metal: chemical and mechanical. The outer part of the pipe and the inner part of the fitting are cleaned of the oxide film, dirt and impurities with a metal brush. In addition, the possible use of steel sanding wool or pelts. After that, the solder is well distributed over the surface.

Convenient in use are nylon-based cleansing wipes.

A significant advantage, which distinguishes them from a metal brush or skin, is that after cleaning the surface with a napkin, there is no cleaning residue left. After napkins on a nylon base, no abrasive crumbs or steel residues are observed on the pipe.

The chemical method involves the use of acid, which reacts with oxides.You can use flux, which degreases the surface and actively fights oxides.

Flux Usage and Assembly Parts

Apply flux to the cleaned surface. It is applied to a section of pipe that will be connected by a fitting or a socket, distribute the flux well on the surface, an excessive amount of flux may adversely affect the connection. But also do not use flux from the inside of the fitting. Regulate paste consumption.

After applying the flux need to properly connect the parts.to avoid foreign particles sticking to the surface. If the soldering will be carried out later, it will be much better that the parts have already been assembled. It is necessary to turn the pipe until it stops, thereby checking its connection and distribution of the flux. After remove the remnants of the flux fabric prepared in advance for work. The compound can be heated.

For low-temperature soldering fluxes are used, in the list of composition of which aluminum chlorides occupy the last place. Fluxes are hazardous substances, therefore it is necessary to ensure that the excess does not remain on the outer part of the pipe. Such inattention can lead to metal corrosion and leakage.After soldering, re-inspect the surface, there will be a little flux on it due to the thermal effect. The flux appearing on the pipe must be removed again.

When high-temperature soldering, borax is used instead of flux. It is mixed with water to a thick consistency of porridge. You can use special pastes for high-temperature soldering. If you chose a copper-phosphorus solder, then you do not need to purchase flux for it, it is already present in the composition. It is better to use a set of one manufacturer, while aligning it with the type of soldering.

Flared thickening

For connections in everyday life, they use either fittings for soldering copper pipes, or bell-shaped thickenings.

It is better to choose the option with a flare thickening, so you will need to put only one seam at the junction of the pipes.

- From the end of the parts are processed milling pipe cutter. The cut must be smooth and strictly perpendicular.

- From the ends of the pipes get rid of the chamfer, using a faskomnitel. Inside and outside surfaces are cleaned.

- One section of the pipe is clamped in a vise, the pipe expander is inserted inside. Then you need to carefully expand the internal diameter of the pipe to fit the external diameter of the second pipe.

Before repairs, do not forget to remove the plastic fragments from the structures, otherwise they will melt and will be unsuitable for use.

Process steps

Consider the process in stages for different variants of compounds.

Connection at low temperature soldering

Experts say that for such work it is necessary to acquire low-melting solder and low-temperature flux. Gas burner can be filled with a mixture, which includes propane, air or butane.

The flame must be directed strictly along the seam of pipes, moving across the entire area of the joint. This is done to evenly heat all areas. Do not forget to periodically grease the gap with solder, gradually it will begin to melt. As soon as the melting has gone, the burner must be withdrawn, and the substance will fill the capillary gap. When the gap is completely filled, the parts need to cool down under normal conditions, without a temperature drop. Not cooled connection is forbidden to touch.

In the process it is important not to burn the copper, it will happen if it is overheated. The flux may break, it will not protect the metal from oxides. This, of course, will adversely affect the operation of the system.

Sometimes it is not recommended to solder any products, in such cases they prefer welding. The process is practically no different from soldering. But before proceeding to the welding process, familiarize yourself with the safety regulations and the progress of work. You will need safety glasses.

High-temperature brazing

The composition of the filler gas burner is changing, now it is filled with propane with oxygen or acetylene with air. Warming up should not take a lot of time, the device should give a blue flame.

The flame, as in the case of low-temperature soldering, must be fed around the entire junction, changing the position of the burner. When the metal warms to about 750 degrees, it will turn a dark red color. At this point, you need to use solder, you can heat it with a burner. However, the solder should ideally heat from the part.

The product must be reported at a temperature at which the solder melts quickly and fills the space between the parts. After full filling, it is necessary to leave the structure to cool.

Do not disregard the joint seam and surface, be sure to remove the flux residues.The finished pipeline is better to rinse with warm water, flush away excess flux and solder.

Repairs

You can do it yourself with the help of problems that have arisen in the water supply system or household appliances, for example, a refrigerator or a split system.

Metal stratification is a common problem. In this case, high-temperature soldering is used, this will significantly extend the service life of the system. A common phenomenon is the appearance of cracks on the bends of pipes. Masters recommend the use of low-temperature welding.

To prevent cracks from appearing on bends, the bend radius itself should be no more than 3.5 times the diameter of a pipe with a diameter below 1.5.

In the repair, it is also necessary to clean the surfaces before starting work, otherwise the structure will quickly fail. When the fitting leaks, you will have to cut this part of the pipe and solder a new one with a new coupling. If a nut or gasket breaks, it is enough to replace only this part.

Safety

Copper has a high thermal conductivity, so you must wear gloves or gloves on your hands, otherwise a burn cannot be avoided. Items are taken only with forceps or protective gloves.

Carefully need to apply flux, make sure that it does not hit the body. Otherwise there will be a chemical burn. If, after all, the substance got into your hands, you need to leave work and wash the place with plenty of soapy water.

The flux burns slowly when heated, its vapors are toxic, so the room in which the work on the soldering of pipes is carried out must be well ventilated.

Pay attention to the clothes in which you are going to do the work. It should not be synthetic, because this material is flammable. It is better to choose clothes from organic cotton.

Masters advise beginners to practice on trimming pipes before starting work. So, after a couple of workouts, the result will be much better.

Causes of defects

The soldering process is not as complicated as it seems at first glance. But most continue to make mistakes.

Consider the most common.

- Defects on the surfaces of pipes, their parts, fittings. Pay attention to the surface of the pipe fittings. Due to such damage, the quality of the seam subsequently suffers.

- Dirt and remnants of any materials on the pipes. After the item has been treated with sandpaper or brush, this part must be treated with a degreaser. Otherwise, residual particles will prevent the compound.

- Poor warm-up parts. If it is bad to heat the part, the solder will not melt with the surface. When a small load will occur stratification along the seam.

- Overheating of the metal leads to disruption of the flux layer, disruption of its protective functions. Oxide and scale appear.

- Premature connection check. Until the structure cools, it cannot be touched, otherwise the pipe will be deformed and will be unusable.

- Ignoring security rules.

- Connection of pipes with too large a difference in diameter. The difference in pipe diameters should be no more than 0.5 mm, otherwise the connection will be fragile and will last a short time.

Master class on brazing copper pipes, see below.