Pipe couplings: variations and their technical characteristics

Couplings for pipes are indispensable in the field of modern engineering communications. Varieties and technical characteristics of pipes allow you to create different configurations of pipelines. Without couplings, only straight sections of water pipes are possible, and their use is limited. Consider the features, norms and types of clutches existing today.

Special features

The considered elements of engineering systems have various features that can be noted as advantages or disadvantages.

Connectors called "coupling for pipes" have the following positive qualities:

- a light weight;

- quick and easy installation;

- low price;

- many varieties;

- possibility of application in many areas;

- mechanical strength.

Some types of couplings have certain disadvantages. For example, elements wear out quickly, become deformed, not all of them are able to absorb vibrations.

To select the appropriate options from those on the market, you need to consider the scope of application of products, as well as the material manufacturing parts:

- Couplings can be tough. These are those that are made of metal. The main scope of such couplings - various lines, with some properties.

- Couplings can be spiral. Such products are usually aluminum. The main feature of products - easy bending. The accessory has a special structure, due to which the given function is provided.

- Couplings can be polyurethane. Inserts of this material are usually placed between two metal parts. Such a coupling is a shock-absorbing element that absorbs a significant proportion of vibrations.

- Couplings are membrane. The main feature of these products is that these elements are prefabricated. They are often used to connect parts placed in different planes. The accessory is not only multifunctional, but also quite durable.

In addition to water pipes, couplings are connected:

- metal cables and ropes;

- axles and thrust;

- machines and mechanisms.

Couplings are used not only in the main engineering systems, but also in the field of shipbuilding, heavy and light industry, in the field of communications. The main feature of joints using couplings is the ability to fasten products of different sizes and from different materials.

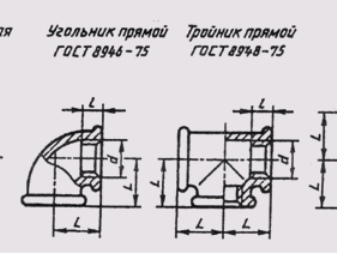

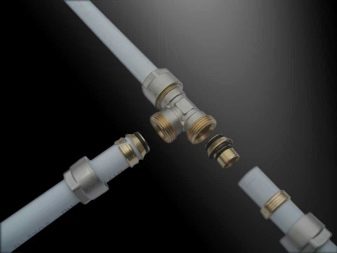

Couplings using couplings can be presented in various forms. The configuration can be ordinary, straight, angular. Often in the highways are used tees, as several other pipes may be adjacent to the main branch. Some couplings are joined by welding, other products are threaded. Manufacturers offer various combination options.

Various materials can be used for clutch production. For example, they are bronze, brass, cast iron and other varieties. In addition, to increase the service life of products, their surface is covered with a layer of nickel, zinc, and chromium. External coloring of products is usually associated with the components used in the coating composition.

Depending on the components used in the manufacture varies the cost of docking valves. Another cost varies depending on how complex the design. Equally important is how much ambition the manufacturer has.

Norms

Choosing couplings for their purposes, it is important to be guided not by cost, but by the norms prescribed by GOST. Often the high price does not mean quality products. The main parameters of the connecting elements are governed by interstate standards. The document contains requirements for calibration, as well as the range of materials allowed for use in manufacturing.

The standard provides for the use of technological processes that can be applied in a particular production. Products manufactured in accordance with the technical documentation, subject to further certification.

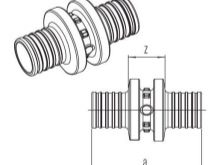

For example, the most popular tool is a steel clutch, straight. It looks like a cylindrical piece with a through hole and a thread inside, which is cut along its entire circumference. The standard GOST of this product is 8966-75.

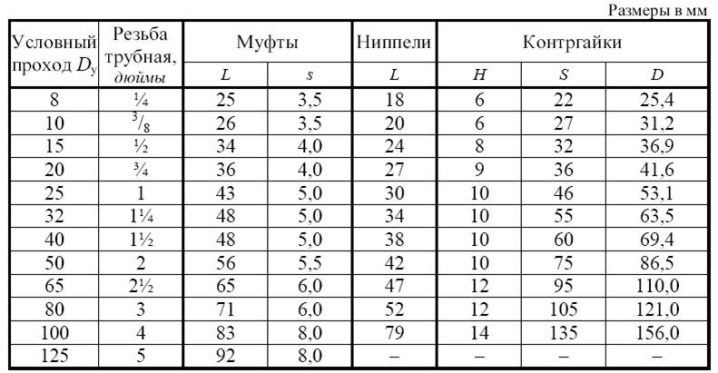

The regulations assume that the connectors can be made of cast iron, brass or bronze from combined bases. Standard top lamination - galvanized. Since there are several types of clutches, they differ in State Standards. For example, 8966-75 - the standard for direct connections, 8954-75 - short couplings.

Couplings of different diameters and dimensions may be included in one GOST.

GOST 8966-75

Conditional patency Du, mm | Threaded connection | length | Material thickness | Weight, kg |

8 | 1/4 | 25 | 3,5 | 0,023 |

10 | 3/8 | 26 | 3,5 | 0,036 |

15 | 1/2 | 34 | 4,0 | 0,067 |

20 | 3/4 | 36 | 4,0 | 0,086 |

25 | 1 | 43 | 5,0 | 0,163 |

32 | 1 1/4 | 48 | 5,0 | 0,220 |

40 | 1 1/2 | 48 | 5,0 | 0,255 |

50 | 2 | 56 | 5,5 | 0,409 |

65 | 2 1/2 | 65 | 6,0 | 0,663 |

80 | 3 | 71 | 6,0 | 0,838 |

100 | 4 | 83 | 8,0 | 1,801 |

125 | 5 | 92 | 8,0 | 2,374 |

(150) | 6 | 92 | 10,0 | 3,560 |

Standard coupling can be threaded or not. Knowledge of GOST helps to accurately calculate the number of products, as well as their cost. The characteristics of the couplings are also prescribed in the GOSTs; they are presented schematically. The presence of a drawing with dimensional characteristics allows you to more accurately imagine how everything will look in reality. Experts identify several types of parts that can be suitable for a variety of cases.

Classification can be represented as follows:

- threaded couplings;

- compression;

- press;

- welded;

- electrowelded.

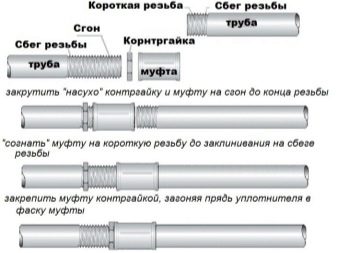

The use of threaded options is limited by the possibility of using in conjunction with steel pipes.Installation of products is complicated, and the connection is considered unreliable.

Compression options are similar to threaded products, since their installation involves the tightening of elements. Tightness specialists achieve installation of sealing rings in the system.

Press models are mounted using special tools. They are at the present stage - one of the popular options for couplings.

Welded couplings are needed when using polymer pipes. Other products simply do not connect these parts. Modern type of welded elements - electrically welded parts. Such a coupling is considered to be more stable, therefore it is considered possible to use even on gas pipelines. Let us examine the presented types of products in more detail.

Kinds

There is a lot of separation of couplings by types.

A large class of mechanical couplings can be divided into two groups:

- demountable;

- all-in-one

One or another type of connectors is selected based on how the pipes are made. Pluggable connectors are divided into coupling and flange. Non-detachable products can be considered some types of coupling joints.

The flange is relevant when connecting large highways.Coupling connectors are relevant for pressure or non-pressure pipelines. Also, this connection is relevant for repair work.

Repair clutch can be:

- crimp;

- shrink;

- protective;

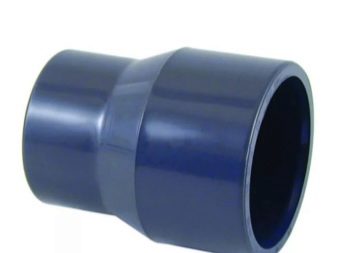

- transitional;

- casing.

Such types as compression, heat-shrinkable, metal hose, sleeveless, American are known. Of the little-known products can be noted compounds PFRK, lead box, made of cast-iron bases.

Flanges are used when reliable joining of main pipes is needed. Flanges usually have two parts. One main, the other response. For the tightness of the connection meets the rubber gasket. The coupler is made in two parts with bolts.

The connection itself can be divided into the following stages:

- preparation of highways;

- installation of the flange on the product section;

- installing a gasket and fastening parts with screws.

The flange connection of pipes of volumetric size allows for reliable and high-quality bonding. The main pipeline is durable and strong. The negative quality of such a connection is the need to periodically replace the gasket, especially if aggressive media are transported in the system.

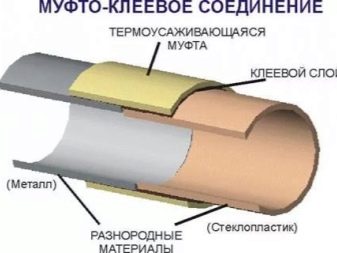

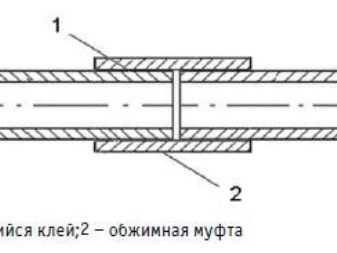

Coupling is also not difficult. During the work it is required only to prepare the pipes, to apply the marking, to apply an adhesive substance on the surface of the pipes, if required by the parts. Then it remains to insert one pipe into the coupling, the other one should be placed along the same axis. It remains to push the second part of the clutch. This method is called gluing.

There is another type of coupling, called welded. They require an arc or gas welder. Connectors are considered reliable and more suitable for splicing polypropylene pipes. The work involves low-temperature soldering. The device is set to the desired temperature and prepared the nozzle of the appropriate size.

Compression couplings can be referred to the type of detachable connections. When using them, no additional equipment or adhesives are required. Compression connectors are permitted for use on trunk pipes with pressures up to 25 kg / cm2.

The body of such couplings can be polyethylene, bronze, cast iron or brass. On the supply elements there is a thread, on which the cap nut is screwed, it can be made of plastic or metal.

Inside the compression sleeve are rubber sealing parts that seal the joints. A collet bushing is put on top of each item to be connected. This part is usually from the same base as the clutch itself. Before installation, the collet sleeve must be inserted into the housing. The entire system is pressed on top by a cap nut. When it is twisted, the split petals of the collet are compressed, holding the pipe inside the body due to the friction force.

Compression couplings are inexpensive, but can be used for pipes with a maximum diameter of about 90 mm. Parts are often chosen for laying networks of hot or cold supply, other communications that may be in home use.

Dimensions

The couplings on the market vary in a fairly wide range of sizes. Permissible limits of products - from 8 to 125 mm. Products with a diameter of 16 to 63 mm are used in highways with pressures up to 16 atmospheres. Products with a diameter of 75-125 mm are used for highways with pressure up to 10 atmospheres.

The size of the pipes is sometimes indicated in inches, which means the parameters of the external diameter. Other units of measurement, for example, millimeters, mean the internal section of the product.Choosing couplings, one should pay attention to the fact that there are no foreign inclusions inside and outside the products. Otherwise, a right angle relative to the axes of the plane in the connecting elements will not be obtained. And this will entail a deterioration in the quality of the pipeline system as a whole.

Consider the following options:

- input dimensions: 16, 20, 25, 32, 40, 50, 63, 75, 90, 110,160 mm;

- output size: 20, 25, 32, 40, 50, 63, 75, 90 mm;

- length parameters: 33, 38.5, 42, 54, 65, 71.5, 82, 93 mm;

- internal thickness: 5, 6, 6.5, 7, 8 mm.

The above parameters are applicable for polypropylene couplings. They, by the way, are normal or transitive. In any case, when selecting products, you can focus on the label, which includes the following information: for example, the MP 37x190 coupling is a transition type with an input size of 37, and the output type is 190 mm. Detailed normative indicators of the product can be studied in the document called GOST 52134-2003.

You can find on the goods such markings as HDPE, DKS. Dn 8 (1/4), which means that the product has a nominal pass of 1⁄4 inches. These products are usually steel, straight shapes. Product specifications can be found in GOST 8966-75.

Marking in inches can be presented in the following variants:

- Dn 15 (1/2);

- Dn 20 (3/4);

- Dn 25 (1);

- Dn 32 (1/4);

- Dn 40 (1/2);

- Dn 50 (2);

- Dn 65 (2 1⁄2);

- Dn 80 (3);

- Dn 90;

- Dn 100 (4);

- Dn 110;

- Dn 125 (5);

- Dn 150 (6).

If you need to convert inches to mm, you can use the following data:

- 1⁄2 inches = 15 mm;

- 3⁄4 inches = 20 mm;

- 1 inch = 25 mm.

Mounting couplings often require additional tightness of the joints. For this junction compacted with special tapes. If the fixation of the product resulted in damage, such a coupling is no longer subject to installation.

Tips

Before starting installation works with polypropylene couplings, special markings should not be neglected on the water supply pipes. Products can be used at temperatures from +5 degrees. If the recommendations on the temperature regime are not followed, this will worsen the tightness and reliability of the connecting node.

On parts made of polypropylene should not be threaded. Do not use tools that are not designed to work with polypropylene products, so exclude gas switches. Before starting the assembly line have a drawing at hand. So it will be more accurate to know the number of couplings and other connections that may be required in the work.

Polypropylene coupling - the simplest type of products. An important rule during installation - do not allow turns.The surface of the pipe will go wave that in the future will lead to leakage.

More professionals advise choosing a coupling from the same material as the pipeline material. If the connection base is different, the reliability of the docking will be significantly reduced. However, in fact, it is often necessary to connect metal-plastic and steel, polypropylene and old water pipes. In such a work can not do without couplings, which are called adapters.

Sealing is made with special tapes or flax. These materials need to be wound on the external thread of products in a clockwise direction. The quality of flax will improve if it is impregnated with linseed oil. In the absence of drying oil, you can use the usual enamel.

The adapter or any other coupling needs to be wound neatly, effortlessly. The external thread of the product must be pre-sealed. In work, first put the union nut on the line, and only after that cut the ring. If necessary, chamfer can be removed from the inside of the pipe.

It’s more convenient to use two keys at once. One of them holds the coupling, while the other tightens the nut.These actions must be very careful, as if the seals are easy to move, the sealing will be broken.

To prevent the connector from being damaged when it joins the pipe, the product can be smeared with liquid soap. This action will also provide the best coupling stroke when connected to a pipe. For better reliability, the joints along the seams can be additionally passed with sealing glue.

Pig-iron and copper connectors are rarely used today, as the modern market offers enough other less labor-intensive products in operation. If you still have to use these species, it is important not to neglect the chasing of the compactor. Sometimes even professionals are limited to the overlay of cement mortar. Such a connection will be unreliable and short-lived, will very quickly let flow. Embossing is done in a few turns, you need to work on the entire product. Only after embossing the joints are sealed with cement mortar.

One of the most resistant to mechanical damage threaded fittings. Means of connection of this type provide a reliable fit. Installation of products is simple, and therefore is popular.Professionals are advised to choose products made of brass or cast iron. Other types of parts stick to the main pipe over time due to the effect of accumulating condensate. In the future, this complicates the analysis of parts, in the course of the work can damage the water pipe or the connector itself.

If the coupling removed from the pipe is not damaged, in most cases the parts can be reused. This statement does not apply to polypropylene or polyethylene products. If during disassembly the clutch remained intact, it is sometimes sufficient to replace the rubber gasket if present. When re-installing the coupling, a reliable fit can be guaranteed.

The product called "coupling" is a universal tool for joining various types of highways. In addition, it allows you to create reliable transitions from one type of material to another. Couplings can also connect highways of various diameters. The main thing, after their installation, check the joints for leakage. If it is not observed, it means that there is tightness in the joint and the resulting compound can be considered reliable. Modern couplings are considered very useful in the repair of old plumbing.

You will learn more about pipe couplings from the video below.