Corrugated pipes: types and scope of application

With the invention of corrugated pipes, construction, utilities and other industries have acquired a serious assistant in all areas related to the use of pipes and the protection of conductive material.

Special features

Corrugated pipes are made from polymers and stainless steel. They look peculiar, having a folded system and a rather rigid ring structure. As for polymeric types, they are single or double layered. Inside the two-layer structure there is an elastic pipe with a smooth surface, it is protected by an outer corrugated layer. Such models have a wide diametral range - from 100 to 1200 mm and a ring stiffness of 4–16 kN per 1 square meter, which helps to use them with maximum capabilities.Manufacturers produce corrugations of different colors: white, gray, black, orange, brown.

Corrugated pipes, despite their mobility, are quite tough and reliable. The degree of stiffness is regulated by pushing the rings. Corrugation is resistant to external influences, because the polymer does not rot, does not rust and does not collapse. It is easy to subordinate the damaged section of the pipe, it almost does not need fittings. The corrugation has a wide scope of application, it is able to pass in hard-to-reach places, it is easy to assemble, it can withstand mechanical loads. The pipes are incredibly flexible, they are easy to deploy and direct in any direction, making installation work as easy as possible, even on surfaces with difficult terrain.

Norms

There are the following normative documents concerning corrugated pipes:

- GOST 51613 - standards for sewer PVC products with a diameter of 10–315 mm are collected;

- GOST 14254-96 - means of protection for polyvinyl chloride (PVC) are marked;

- Polymer products manufactured abroad are protected by state standards of other countries, for example, EN 13476-3 is adopted in the European Union.

Kinds

To date, varieties of corrugated pipes are quite a lot.They have a different diameter, wall thickness, length and color. There are power and low-current cables, single-layer and double. They are distinguished by several criteria.

According to the type of strength, several types of corrugated pipes are distinguished.

- Lightweight corrugated pipes are designed to work on indoor surfaces, as they cannot withstand the load, for example, for installation underground. Lightweight models are the most flexible and maneuverable options. They bend at any angle. With their help, you can facilitate repair work and save on connections.

- Heavy pipes are well mounted, carry heavy loads. They can be placed underground at a depth of 15 m.

- Super-heavy products have increased mechanical strength, cope with large loads. Such pipes are laid under heavy soils, buildings, highways. They can be concreted. In super heavy corrugation pave the electrically conductive system in places with large concentrations of people. They are safe even with high voltage cable content - up to 2000 volts.

The material of corrugated tubes are of several types.

Corrugated pipes are made from metal and various polymers, such as:

- aluminum and stainless steel;

- PVC - polyvinyl chloride;

- PTN and PE - polyethylene modifications;

- LDPE - high pressure polyethylene;

- HDPE - low pressure polyethylene;

- PP, PP - polypropylene;

- PA - polyamide.

PVC

Polyvinyl chloride pipes are the most popular today. They do not propagate burning, therefore they play the role of a cable channel for the construction of electrical networks. PVC is an excellent insulating material. Unlike a polyamide tube, it withstands voltages up to 2000 W with a resistance of 100 Ohms, but it does not tolerate ultraviolet light. These products are good for indoor work.

In PVC pipes, you can lay a cable for different purposes (telephone, television, electric). The design has a protective dielectric layer, protects against mechanical damage. PVC is used in plumbing and as a drainage pipe. Heavy PVC pipes are used for the construction of communications associated with increased loads. PVC can withstand temperatures from -20 to + 60 degrees.Some types of pipes are endowed with a probe, with which it is easy to pull the cable through the cavity of the corrugations.

The mobility and light weight of the pipe facilitates the installation of the entire system. Cut corrugation can be any cutting tools. PVC is attached to the surface with plastic clips. Polyvinyl chloride is not fire hazardous at all; it decays when released into a source of ignition. It is a moisture-resistant, wear-resistant material that exhibits inertness to aggressive environments. But it is deformed at high temperatures, but perfectly tolerates low ones, and also does not crack, even when completely frozen.

LDPE

High-pressure polyethylene distributes combustion, and although outwardly it does not differ from PVC, it is not used in work with electrical wiring. Such pipes should be laid in a hidden non-combustible environment, for example, concreted. Unfortunately, this feature limits the scope of the LDPE. Unlike PVC, polyethylene is recycled, which has a positive effect on the environment. LDPE has a large working temperature run-up: from -50 to + 80 degrees, but does not tolerate oxidation and is sensitive to gas vapors.

HDPE

Low-pressure polyethylene is waterproof, resistant to chemical attack, but resistant to mechanical damage. With it, you can lay the cable to a depth in the ground. Corrugation is poured with concrete mortar or protected by brickwork. PND does not react to the acid-base environment, has a special strength and durability, and also has a high elasticity, therefore, remains intact even when it freezes. Low-pressure polyethylene is used to lay the drainage system and external sewage. Ring stiffness allows the use of HDPE at great depths, and the flexibility of the product makes it possible to mount it virtually without the use of fittings. Ease, durability, elasticity and durability of PND allow to operate the pipe for a long time without repair. But the pipeline material should be protected from high temperatures and ultraviolet radiation.

Stainless steel

Not all polymer pipes are able to withstand high temperatures. Corrugated stainless steel is indispensable for water heating. Cold-rolled steel pipes require welding during installation, and corrugated stainless steel structures invented by the Japanese are easily installed, which speeds up construction processes.South Koreans were the first to react to the useful invention of the Japanese and put the production of pipes on stream. Kofulso products are known all over the world. Somewhat later, other European countries joined the launch of stainless steel corrugations.

The pipes are made from metal with the addition of nickel and chromium, and the percentage of chromium is quite high (18%), which gives a complete guarantee of the absence of corrosive processes. The corrugation has a working temperature run from -40 to +150 degrees, briefly withstands heating up to + 600 degrees. The pipe is not deformed when it freezes inside the liquid. A large percentage of strength gives it the ability to withstand water hammer. The corrugation is mobile, able to bend up to 30 times in one place, not allowing deformation. Depending on the diameter of the product bends from 30 to 150 mm.

During assembly, ordinary brass fittings are used. They have different diameters and configuration, they are able to easily connect pipes with each other and even with old plumbing structures. It is practical to use a flute in the plumbing system. The perfectly polished inside of the pipe prevents deposits. The metal is quite resistant to the manifestation of mold, fungus, it is not afraid of rodents and the sun's rays. Corrugated stainless steel has an unlimited shelf life.

Dimensions

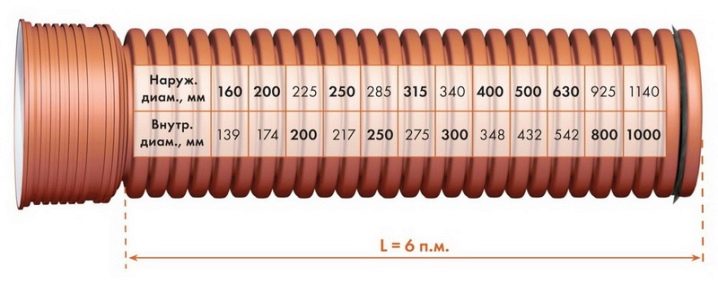

Corrugated produce for many needs. It is necessary both for carrying out power and computer cables, and for volumetric work in the sewer system. To meet the multi-faceted consumer demand, corrugated products produce various diameters, wall thicknesses and footage. For example, for laying the cable may need pipes from 16 to 160 mm in diameter.

Among the most popular options worth noting the following:

- pipes with a diameter of 10, 16, 20, 25, 32 mm have a length of from 100 to 500 m, wall thickness - 2 mm;

- corrugation with a diameter of 40 mm is available in lengths from 100 to 200 m with a wall thickness of 3.7 mm;

- 50 and 63 mm in diameter can be found in hundred-meter pipes;

- large diameter pipes - 90, 110 and 160 mm are produced by twelve meters;

- Stainless steel corrugation is produced with diameters of 12, 15, 20, 25, 32, 40, 50 and 60 mm, while the wall thickness is 0.25–0.3 mm.

The different volume of corrugated pipes solves different problems. To lead the wiring to the chandelier and other lighting fixtures, a diameter of 16 mm is sufficient. To the sockets and switches down the pipe 20 mm. For interior wiring using corrugation with a diameter of 25 mm or more. Inter-panel cable conduits provide for a 32 mm pipe diameter.Interfloor connections of nodes require a capacity of corrugations of 40-50 mm. Lay cable for telephone, computer, alarm can be in pipes with a diameter of 16 to 20 mm.

Scope of application

Folded system designs are widely used in such areas as:

- rainwater drainage system;

- disposal of municipal and industrial effluents;

- drainage assembly;

- heating and culvert system;

- the flow of water into the apartment under pressure;

- gas supply inside buildings;

- sanitary model corrugations for sewer system;

- pipeline for fuels and lubricants;

- ventilation system;

- connection of air conditioners;

- sheath protecting electrical cable;

- warm floor system.

Important: surface area in the form of corrugations has a large heat transfer, it is used in heat exchangers, and a densely looped pipe can perform the task of a radiator.

It is worth considering in more detail the options for the use of corrugated pipes.

- For cable laying. Folded pipes are needed for the construction of electrical, television, computer, telephone cable in the domestic and industrial areas.Corrugation guarantees a high degree of protection against weather conditions, mechanical stress, and also performs the functions of a dielectric layer. The most common use of PVC pipes, because they are easy to transport and store, they do not need welding, are installed without grounding. Polyvinyl chloride is not flammable, it is used to protect electrical wiring. In the folded pipes can be carried out as low-current and power cable.

- In the construction and utilities system. Corrugated pipes are widely used in the construction of the residential sector and industrial premises for the installation of communications. Corrugation is used for cold and hot water supply, in heating systems, gas supply of houses. In apartments it is extremely easy to move the folded pipe from the exhaust hood to the ventilation well. It can be used in virtually all rooms, mounted on walls or applied externally.

- For sewers. Sewage pipes must be designed for heavy loads. Some types of corrugations do an excellent job with this task, they are laid underground, they are resistant to corrosion, mechanical stress and frost.Their good performance makes it possible for many years not to engage in repair work, but it is recommended to perform technical inspection of pipes annually. To combat congestion, chemical purification methods are used or hydrodynamic cleaning is used, when steam or water is loaded into the system under high pressure, which allows for clearing congestion. For sewage use rigid types of corrugations of large diameters.

- Drainage system. The drainage corrugated pipe is made from PVC for carrying out of a water supply system from various objects. In everyday life, this corrugation is not very suitable, as it softens at temperatures above +65 degrees. It is better to use products made of polyethylene (PE) or polypropylene (PP).

- Warm floor. For the "warm floor" system, excellent characteristics of corrugations made of stainless steel are suitable: high heat dissipation, reduced linear expansion, temperature capabilities. For floor equipment, pipes of diameters of 12 and 15 mm are used with a length of 50–60 meters.

Corrugated pipes are a frequent guest in houses and apartments. Their light weight and simple assembly allows many owners to independently carry out the installation of these products.When you buy the flutes in the kit are fittings. To connect them to the mixer or faucet, use a strip of rubber or polymers. Before use, it is necessary to loosen the fitting nut on the side of the intended fastening. The pipe can be cut using a roller pipe cutter or any cutting tool. The incision should be processed by cleaning the burrs and achieving smoothness.

Corrugation must be carefully straightened, giving it the desired shape. At the next stage, the pipe is connected to the fitting all the way and fixed with a flare nut, while you can use a wrench, but not be very zealous to prevent disruption. The nut is firmly pressed into the ribs of the corrugations. The pipe is attached to the surface with plastic clips, fixed with nails. Upon completion of the design should be tested under water pressure. If leakage is detected, the fitting nuts will have to be tightened. Installation of corrugated pipes is much faster than working with any other materials.

Tips

On installation

For proper installation and operation of corrugated pipes you need to know the following nuances:

- prevent the installation of defective products or metal corrugations with signs of corrosion;

- when installing a folded pipe, it should be checked that there is no tension and twisting;

- pipes with bends, cracks and deformation cannot be put into operation;

- it is not necessary to make installation of a warm floor out of pieces of corrugations, work should only be done with the whole pipe blank;

- when piping stainless steel, avoid contact with corrosive ferrous metals; connections must be made of plastic or brass;

- undesirable contacts of metal corrugations with electric current;

- do not exceed the number of kinks specified by the manufacturer;

- Assembly should be carried out according to the instructions, after completion of the system should be checked under pressure.

Optionally

When choosing a corrugated pipe The following expert advice should be considered:

- when buying, you must check the complete set of fittings;

- the pipe should not have creases, dents and other damage;

- fittings should be purchased from the manufacturer of the company that purchased the pipes;

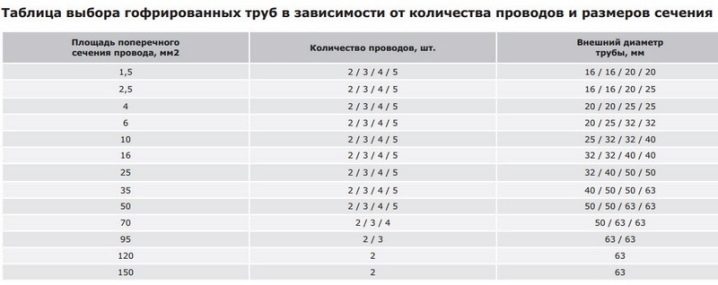

- the size of the corrugations depends on the volume and size of the cable being pulled and its purpose;

- It is better to choose a corrugation with a probe, which will facilitate its further use.

Advantages and disadvantages

In conclusion, it is worth highlighting the following Positive aspects associated with the characteristics and use of corrugated pipes:

- PVC is fire resistant, melts and extinguishes fire;

- such products have dielectric resistance;

- the pipes are characterized by ring stiffness, which makes the products very durable;

- polyesters are waterproof;

- corrugated pipes can serve for a very long time;

- PVC is a good insulator;

- pipes have low toxicity even during melting;

- flexibility gives you an edge where you need to go around corners and take turns; this quality is perfect for work indoors and in difficult landscape areas;

- easy pipe assembly;

- chemical resistance;

- not susceptible to mold and mildew;

- do not rot, do not corrode;

- resistant to water hammer;

- have good protective properties for conductive cable;

- the presence of the probe helps to advance the cable inside the corrugations;

- do not require grounding;

- compactly packed in coils, which makes them convenient for transportation;

- have a two-layer system;

- pipes can be installed in concrete, plaster, laid deep underground;

- Some types of flutes withstand large temperature fluctuations.

It will be fair to note such disadvantages of corrugated structures as:

- PVC is not able to withstand too high temperatures;

- PVC should be installed at a temperature not lower than +5 degrees;

- PVC is not resistant to ultraviolet, it should not be laid on the street;

- despite the high resistance to mechanical stress, the folded tube will not withstand strong blows, a protective cover is required;

- corrugation is not able to fit into every design;

- fasteners should be checked periodically;

- corrugation is difficult to clean from dust and dirt, it is better to immediately use the protective cover;

- stainless steel pipe loses some of the heat during the delivery of hot water through the pipeline;

- the corrugation should not be squeezed with sharp corners, its turns should be smooth;

- You can not stretch several networks in one pipe.

Corrugated pipes are an amazing invention, even despite some shortcomings, it will be difficult to do without them in the modern construction world.

How to choose a corrugated pipe for heating and water supply, see the following video.