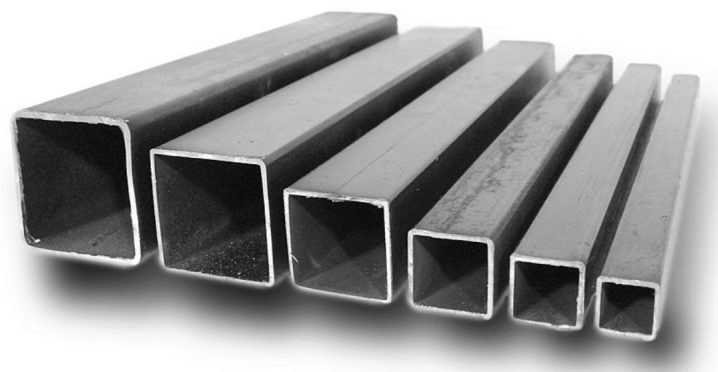

Galvanized profile pipes: characteristics and application of products

Galvanized profile pipes are a common material for the manufacture of various designs. They are widely used in construction, landscaping and everyday life.

Special features

The profile galvanized pipe is a product with a rectangular, oval or square cross section, made of high carbon steel by cold or hot rolling. The production technology of shaped pipes consists in forming an electrically welded pipe of circular section from a steel sheet with the subsequent imparting to it the required forms. The forming of the pipes is carried out with the help of special rolls, after which the weld is tested for strength and the final heat treatment.From above the pipe is covered with a layer of zinc, due to which it acquires the highest anti-corrosion properties, does not oxidize and does not rust.

The most effective method of galvanizing pipes is hot dip galvanizing, in which the process is carried out in special chambers under the influence of high pressure and the complete absence of oxygen.

Such products are characterized by increased resistance to moisture, thermal endurance and resistance to thermal shock. This allows the use of galvanized pipes in any climatic zones, including areas of the Far North. The service life of galvanized products exceeds the service life of non-zinc coated models by 5 times. Profile square tubes are manufactured according to the conditions of GOST 13663 86 using doped and carbon steel grades St 2ps, St 4ps, St 4kp, 10ps and other high-strength types. Rectangular models are produced in accordance with GOST 8639 62.

Advantages and disadvantages

High consumer demand and demand for a galvanized profile are due to a number of indisputable advantages of this material.

- High strength and durability allow you to use the car as the basis for the frame in the construction of any industrial and civil structures.

- Anticorrosion properties of pipes provide ample opportunities for their application in any climate without restrictions.

- The low cost and availability of the profile significantly expands the scope of its use, making it widely available to all segments of the population.

- Low weight in comparison with structures made of low carbon steel makes the structure being built strong and light at the same time.

- Convenient storage. Due to its square or rectangular shape, the pipes do not roll out and do not create additional difficulties during their storage.

- Convenience and ease of self-assembly also due to the shape of the cross section of pipes.

- High resistance to mechanical and weight loads is achieved due to the presence of stiffeners. This is the main difference between the profile models from traditional pipes with a circular cross section.

The disadvantages include the difficulty in self-bending the profile, which is due to the high strength of stainless steel, as well as the difficulty in transporting particularly long models.

Kinds

The range of galvanized pipes made of stainless steel consists of shaped shaped articles that have a rectangle, oval or square in cross section. Depending on the parameters of the wall thickness of the pipe are divided into thick-walled and thin-walled models. The choice of the desired product is carried out on the basis of the operational characteristics of each type, which can be learned from the specialized tables contained in the accompanying documentation, which is attached to each batch of the profile.

According to the method of manufacturing the profile pipes are of two types: welded and seamless.

The first ones are made by welding and are characterized by thin walls and a more limited margin of safety. The advantage is lower price and low weight. Welded models are used in the construction of greenhouses and benches, as well as for the construction of light pavilions and partitions.

Seamless patterns are distinguished by the absence of a weld, due to which they have increased strength and durability. They are applied in all areas of construction and improvement. Seamless pipes, in turn, are divided into cold and hot-rolled.The former are characterized by exact dimensions, resistance to hydraulic shocks, resistance to extreme temperatures and thermopumps, as well as the possibility of independent bending.

Hot-deformed products are quite resistant to soil fluctuations, mechanical and shock loads, they are well tolerated by water hammer, pressure drops and temperatures.

Pipes have thicker walls and dimensional errors.which often make from 3 to 5 mm from declared upwards. Its working qualities, cost and purpose depend on the method of manufacturing the pipe. The most durable and durable models are hot rolled. Products made in the cold way are somewhat inferior to them in their performance, but they are distinguished by lower cost and a wider scope of application for economic needs.

Dimensions and weight

The galvanized profile is produced in a large size range, which allows you to easily select the necessary along the length and width of the pipe. The material is produced in dimensional and non-dimensional variants, which greatly simplifies the selection and eliminates the need to acquire extra meters.Pipes made in different ways have different lengths. For example, hot-rolled models are available in lengths from 4 to 18 meters, while the length of electric-welded specimens is only 5-9 meters. Cold-deformed pipes, the length of which varies from 4.5 to 9 meters, have the same dimensions.

A special feature of dimensional models is their manufacture with allowances for possible connecting seams, which is very convenient when calculating the required amount of material.

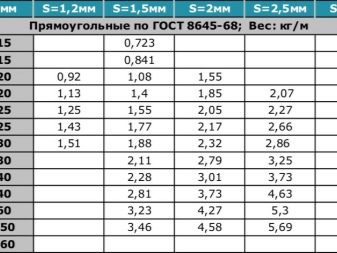

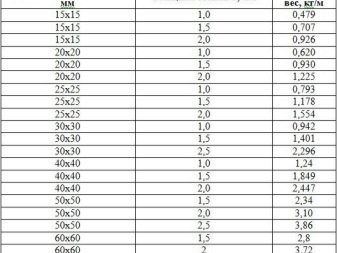

Profile profile is quite diverse. The size of sections of square and rectangular pipes varies from 10x10 to 500x400 mm, and the thickness is 1-22 mm. Thus, the wall thickness of square tubes varies from 0.8 to 14 mm, and the outer dimensions of the width are 10-180 mm. The most common sizes of pipes with a square section are 20x20 and 40x40 mm. Oval products have a wall thickness of 0.5 to 2.5 mm, and the outer diameter can be from 3x6 to 90x32 mm.

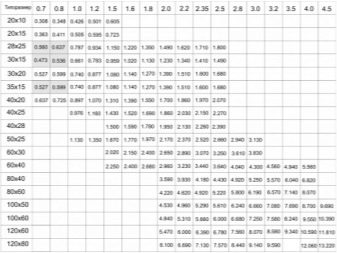

The weight of the profile tubes depends on the wall thickness and size of the section of the model. Thus, one meter of a square product with a cross section of 20x20 mm and a thickness of 1 mm will be 583 grams, and a meter of a product of 100x100 mm and a wall thickness of 6 mm will weigh 17 kg 220 g.For a more accurate calculation, use the table for calculating the weight of shaped tubes. All parameters of the galvanized profile are indicated on the label applied to each product. On models with a small section, the inscription may be absent, but in this case, it is always available in the accompanying documentation, which is attached to each consignment of goods. The marking must indicate the steel grade, the size and shape of the pipe section, as well as GOST and the method of manufacture.

Scope of use

The scope of galvanized profile pipes is very wide. The material is successfully used in the construction of buildings and structures, warehouses and hangars, light trade pavilions and highways. Thin-walled products with a small cross-section are excellent for mounting fences and partitions, public transport stops, manufacturing benches and trading trays. Thanks to the galvanized surface, the pipes can be used without fear in the Arctic and in saline ocean waters.

The use of the profile in the construction of temporary and permanent structures significantly reduces the load on the ground, providing ample opportunities for the use of a variety of building and finishing materials.

In addition to construction, profile pipes are often involved in the installation of children's and sports grounds., installation of machine-building equipment, in shipbuilding and automotive industry. In agriculture, the profile is used for the construction of greenhouses and greenhouses, in the construction of premises for the maintenance of livestock and poultry, as well as in the process of building garages and sheds intended for storing agricultural and harvesting equipment. Galvanized pipes have found application in the advertising business. With their help, the installation of billboards, pillars, billboards and signs installed along highways and in busy places. The material is also very popular among landscape designers. With it, you can create interesting installations in the urban environment, and on the plot.

Despite the fact that the visually tubular galvanized models lose a little to the mirrored and polished surfaces of steel metalwork and look simple enough, in their performance, strength and durability, they are practically unrivaled.

Tips

When self-assembly of structures made of galvanized profile, it is often necessary to give the pipe a certain shape. There are several ways to bend a profile pipe without using expensive equipment and without attracting specialists. If, when working with a round pipe, there are no difficulties in bending it, and it is enough just to warm up the product and bend it at any angle, then using square or rectangular models, this method is not suitable. It should be noted right away that bending of profile pipes is a rather laborious process, requiring great care and accuracy, otherwise there is a chance to break the section geometry and flatten the pipe.

In order to reduce the risk of deformation of the product, you must first place the pipe in the refrigerator and freeze. In the conditions of negative temperatures in the cold season it is enough to leave the rental outside for a few hours.

Before the start of freezing, one of the ends of the pipe is tightly closed with a plug, and water is poured inside the product. Then the second end of the pipe is closed, after which the profile is placed in the freezer or taken out in the cold.After the water inside the pipe freezes, the bending process will be much easier, and the risk of deformation of the product during bending will be significantly reduced.

In cases where freezing water inside the pipe is not possible, the liquid is replaced with sand. At the same time, 2-3 small holes are drilled in the pipe, designed for unobstructed release of gases generated in the process of further heating of the workpiece. If the drilling of holes is neglected, there is a risk of deformation of the pipe, which can no longer be fixed. After filling the cavity of the pipe with sand has been made, you can proceed to bending the product. To do this, heat the area designated in advance using a blowtorch or a gas burner, and bend the product to the desired angle.

The second way to give the pipe the desired shape is to use a special tool - pipe bender. The use of this simple tool allows you to bend the pipe without resorting to pre-filling, freezing and heating products. Pipe benders are roller and hydraulic. Because of the ability to give the workpiece a bend of any radius,Roller models are often called "profilegibs." The bending of the profile on such an adaptation occurs according to the principle of pipe rolling. Hydraulic models are able to bend the workpiece at any angle and are notable for their ease of use and accuracy of the bend point. The advantages of using benders are the application of minimal effort in the process of installation, the absence of the risk of the formation of creases from fastening and flattening, guaranteed accurate forms of bends, as well as the elegant look and decorative appeal of curved structures.

Profiled galvanized pipes are high-strength building materials, allowing in a short time to build a kiosk or pavilion, install a power pole or assemble a greenhouse. And the low cost and consumer availability of pipes make the scope of the profile even wider and more diverse.

In the video below you will see the production of shaped tubes.