Pipe insulation: choice of materials and installation technology

In the modern world there is a huge number of pipelines and pipes through which heat enters the room, gas and oil products are supplied. For all types of pipes require reliable corrosion protection, heat-insulating and waterproofing layers. Let's take a closer look at what is insulation of pipes from various building materials, and also we will get acquainted with the methods of installation.

The need for thermal insulation

Under pipe insulation often understand the insulation of various types of pipes (plumbing, sewer, heating). Insulation allows you to reduce costs and improve the performance of all structures.

Pipe insulation has a different purpose in different room designs.

- In heating systems for the concentration of heat on radiators. The main purpose of heating radiators is to warm the air effectively. Thermal insulation for heating pipes does not allow to spend heat on the heating of walls and technical openings, all the heat enters the room. If the room is heated by a 2-circuit boiler, then due to the difference in temperature, condensate will constantly collect on the non-insulated pipe, all liquid will flow into the room.

- In designs of cold water supply to ensure the required degrees of cold liquid. In modern buildings, pipelines are installed in common mines and grooves. In the water pipes located in the basement of an apartment building, uninsulated pipes without cold water supply (at night or in your absence) from nearby hot pipes heat up, as a result of which, when opening a tap, no hot water flows from the pipe, but hot water. Thermal insulation is also useful for cold water supply systems in that it does not allow the natural humidity of the air to this system.

- In the construction of a hot supply of water to increase the efficiency of the use of a water-heating boiler.In circulating hot-water systems, in the absence of an insulating layer, additional energy will be required for heating the boiler, which prepares the hot liquid so as to compensate for the loss of energy from uninsulated pipelines. In dead-end constructions, uninsulated nozzles lose thermal energy within 30 minutes, while the insulated structure cools down 4 times slower.

- In street routes to save heat. Insulation on the street is provided in cases where the site has several heated structures (a private house and a separately installed bath) that receive heating from a common boiler house. The uninsulated design is able to freeze within 24 hours, and the insulated within 48 hours.

- In sewer systems for those cases where the pipeline is located close to the level of soil freezing.

- In ventilation designs. A ventilated system is necessary to maintain a certain amount of moisture and temperature in the room. It also requires isolation. This is timely for systems located in attics during the winter, when the pipes are very hot from the inside, and from the outside they are blown with cold air flow.As a result, condensation forms on the surface of the structure, which can damage the material. Proper insulation will protect the system from negative results.

Water heating systems installed in the wall are not able to lose their ability to thermal expansion.

If there is no insulation layer, then these efforts begin to take on layers of plaster or screed. As a result, cracked walls are formed on the plastered walls. The use of thermal insulation leaves a gap between the pipe and concrete, which significantly reduces the likelihood of cracking.

Materials

On sale there is a huge range of insulating building materials. To make the right purchase, you must take into account the peculiarities of the building, its size and technical conditions of service of the pipeline system.

The main factors influencing the choice of insulation:

- the location of the pipeline structure;

- temperature regime of the coolant moved through the system;

- the main qualities of building materials intended for pipe insulation.

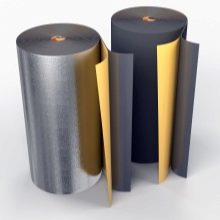

Foil Insulators

Thermal insulation of heating systems is considered effective if it can not only save energy, but also reflect it into the environment. In this situation, experts advise to opt for the material with aluminum foil.

This polished building material has a high reflective performance.that allows you to keep the temperature of the coolant and delay at the maximum level of efficiency of the heating system. The heat flow from the pipeline is reflected back.

This type of thermal insulation of various thickness for pipes running through the living quarters, basement or attic space is made in the image of the shell, rolls, slabs, linen, mats.

Foil insulated building material can be used at temperatures from -60 to +150 degrees, so it is used for external sections of heating mains. Foil insulation does not have a high thermal conductivity, it is not used individually.

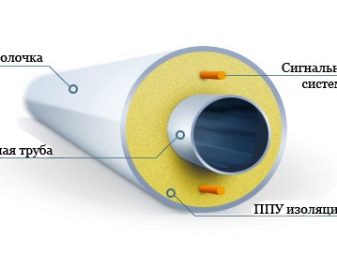

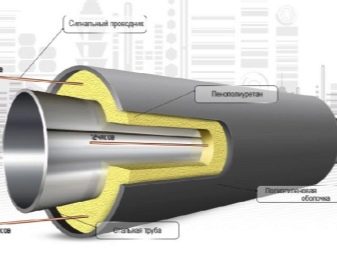

Polyurethane foam

Insulation of polyurethane foam is a solid form design, which consists of walls and edges. This material is manufactured under production conditions by the method of a pipe in a pipe.Insulation of polyurethane foam is also called insulating shell. It has a high durability and well holds thermal energy inside the pipe.

The advantages of using polyurethane foam are:

- environmentally friendly material;

- resistant to chemicals (alkali, acid);

- high resistance to aggressive conditions.

Polyethylene foam

Polyethylene consists of a shell in the form of a pipe. This material covers the pipeline as much as possible and protects it from aggressive media. Any beginner master without special skills will cope with such product. It is enough to cut the polyethylene pipe along a special seam, put it on the pipeline and glue it back.

Liquid thermal insulator

High quality material that can compete with similar products. The composition of the paint insulation is made on the basis of perlite, ceramics and foam glass with the addition of various components. The superiority of the use of this material is environmental safety. Thanks to its liquid consistency, it easily penetrates into hard-to-reach areas.One coat of paint is capable of replacing a 5 centimeter layer of polyurethane.

The paint is harmless to humans and the environment, does not have a specific flavor, and therefore does not require ventilation. This thermal insulator protects metal structures from corrosion, is highly resistant to high temperature conditions, is used both in everyday life and in industrial production.

This type of insulation is produced in the form of an aerosol, which makes it extremely easy to apply.

Mineral wool

Mineral wool used for insulation of pipeline systems is in high demand among users. Its installation is easy to do with your own hands, even in the absence of a certain experience with such works. Among the positive qualities of this building material should be noted high resistance to fire with a low rate of thermal conductivity.

Mineral wool is used not only as an insulating material for cold water pipes and heating systems in the apartment, but also for trunk systems.

Energoflex

Insulation for the heating system is the most popular in our time.Such insulating material should be considered separately. It is used for insulating structures of small diameter (heating, water supply, ventilation, air conditioning).

Energoflex is available in rolls or in hollow tubes with a size of 1-2 meters, having a cylindrical shape of various diameters with a longitudinal notch. Before starting work with such material, it is necessary to check the condition of the pipeline. It must be cleaned and degreased. During installation, the water supply is prohibited, and after they are carried out it is impossible to turn on the water for another 24 hours.

Features of the device

The differences in the insulation of pipelines from other communication structures and the adjacent special equipment lie in the conditions of operation, installation and rules for special maintenance of the coolant. For example, high-pressure gas circulation conditions deduct the smallest vibrations or shock effects. As a result, the insulating building material should act as a damping gasket. This activity is best performed by slabs made of mineral wool, but only if the power frames are connected.And backfill insulation systems for this case will not work.

Individual rules apply to the isolation of systems operating in the chemical and pharmaceutical industries. Such enterprises produce medicines and food products, which are not allowed to contact with various contaminants.

Therefore, thermal insulation should be environmentally friendly, as well as to prevent the ingress of harmful fumes from the circuit. For these tasks, materials from mineral wool, basalt fiberglass are used, but under the condition that the whole structure will be under a metallic coating and in a covering material of glass cloth. Usually, insulation is manufactured as a multilayer building material, in which a separate layer performs a specific function.

The simplest structure is formed by three levels.

- The main layer. Solid base adjacent to the mounting surface. Such a substrate should be resistant to thermal, wet and chemical influences.

- The middle functioning layer. Basically it is made of sealing building materials, with which thermal insulation, noise insulation and waterproofing is performed.

- Protective outer layer. In centralized pipeline systems, it is mandatory, because it is able to protect the structure from mechanical effects.

Mounting methods

Let us consider in more detail the ways of insulating various piping systems that can be performed independently without the help of specialists.

Insulation of water pipes

To produce thermal insulation of a water pipe, mineral wool is used as a heater.

This method is most suitable for indoor use or for elevated street water supply.

- Determined by the total consumption of building materials. In addition to mineral wool, you will need waterproofing in the form of dense foil material or UV-resistant polyethylene.

- It is necessary to carefully process the pipe. It is cleaned, degreased and coated with special enamel. This procedure is necessary so that the structure under the thermal insulation layer does not collapse.

- After that it is necessary to prepare pieces from one whole sheet. The parameters of the segments must be such that they wrap the pipeline once. Cotton wool is applied tightly to the socket,only in this case will the necessary insulation value be ensured.

- Aluminum tape is used for temporary fixation of the warming material.

- Insulation should be brought to areas where the pipe enters the wall, often these places are prone to freezing.

- After the entire section is covered, it is required to perform protection for the wool. For this purpose, it is wrapped with plastic wrap or aluminum foil. Sheets should be mounted in such a way that an overlap of 15 centimeters is obtained. It will be an obstacle to moisture under the insulation.

- For additional fixing, special fastening is made by means of a kapron cord or knitting wire, which is superimposed on the pipeline in the form of a snake.

If you use ready-made special elements of mineral wool, which are produced in a cylindrical shape, then they are put on the pipe, and the joints are glued with aluminum tape.

For effective insulation of the crane you need to disconnect the handle from it. In the warming material a hole is cut for the fastening tool, after which the insulation is put on it, and then the handle is screwed.

Insulation of the heating system in the street

To insulate the heating pipeline on its own is real in most cases.

- The metal pipe is cleaned and primed with a brush to protect against rust. After that, the pipe is wrapped in a spiral method with foil tape.

- Stacked warming material.

- The resulting joints and seams secured with wire.

- For tightness of the construction, reinforced adhesive tape is laid on top of the insulation.

Working with plastic pipes on the street is more simplified, because such products do not need a primer.

Thermal insulation for pipelines made of polystyrene foam is made of two parts, fixed on the pipe by aligning the grooves provided by the manufacturer. To effectively insulate piping structures on the street, it is enough to purchase foam cylinders in accordance with the size of the pipe. This also applies to other construction materials manufactured in the form of casings.

One-piece tubular materials are put on the pipeline when the heating structure is installed from scratch. When pipe insulation is carried out on the street separately, such products are pre-cut along,then perform sealing seams specialized adhesive solution.

How to put a polypropylene pipe into thermal insulation, see the video below.