How and what to cut pipes of different sections and materials: options for solving the problem

Installation of pipelines is not complete without fitting materials, which provides for cutting pipes to the required size. If you have to cut pipes often, homeowners usually stop using the services of professionals. Cutting steel pipes on their own is easy, in addition, it allows you to significantly save money.There are many methods of cutting pipes at home. This article covers all options.

General recommendations of specialists

Bulgarian

The use of grinders - a very popular mechanical method, which is used both at home and in production. Grinding with a grinder requires the master to be extremely careful. Care should be taken to protect hands and eyes with gloves and goggles.

It is also important to adhere to the following rules:

- Work with the grinder must be carried out by a master who has experience with this tool;

- equipment is important to firmly fix;

- you can not handle concrete or stone disc, which was originally intended to cut metal;

- in order to avoid disc “popping out”, the direction of movement of the grinder must be controlled, it must coincide with the direction of rotation of the disk;

- the tool must be closed by a protective casing, otherwise work cannot be carried out.

Roller pipe cutter

In this tool, the active components are the rollers. They carry out the cutting, moving in the cage, installed in place of the future cut.The pressure with which the rollers will be pressed against the material is controlled with screws. To do this, produce a swinging movement up and down, at the same time, the rollers are pressed against the material.

High temperature cutting

This cutting method is characterized by high productivity and low energy consumption.

Gas cutting

This method is best for cutting large pipes. Burning down, the fuel melts the metal and removes it with a stream of gas, blowing it out of the cut. When laying highways from pipes of very large diameter, the use of hand-held equipment is absolutely inefficient and costly. In such cases, use large machines.

This solution allows you to make a cut of high precision, while increasing the speed of cutting the pipe.

Plasma cutting material

The temperature at which metal products can be melted is created by the flow of a substance brought to a state of plasma. Air is used to form the plasma. The enrichment of ions produced by the action of an electric discharge. As a result, this process produces a high temperature. Plasma cutting of pipes is considered one of the best.

The metal pipe is processed in this way with 100% quality.

Use of laser

The laser machine is a fully automatic system. With the help of such a device you can cut, mill, drill, process edges.

With this tool you can process pipes of the following parameters:

- diameter (maximum) - one hundred fifty millimeters;

- length (maximum) - six and a half meters.

In this way, stainless steel pipes are best treated.

Profile pipe: how to make exactly?

All of the above metal cutting options are also suitable for cutting shaped tubes. It is especially difficult to cut not round, but square shaped pipes. The accuracy of the marking is extremely important. By doing this manually, you can make mistakes and cut off incorrectly. In this case, the elements of the future pipeline during assembly will not dock.

To eliminate possible errors in the wizard, it is recommended to create a template from a piece of the same type profile with a large cross section.

Making such a template is an easy process.

- Measure with a protractor on a pipe trimmer and measure an angle of forty-five degrees.

- Make a cut grinder, then grind the edges trim.

- At the end of the grinding insert into the prepared template a pipe from a profile having a smaller diameter.

- Create a full markup on the created protractor by the scriber.

- For this workpiece, cut the pipe with a grinder.

- At the end of the work carefully grind the edges, so as not to get hurt about the burrs.

Metal-plastic pipes: what to cut?

The simplest equipment with which you can cut a metal-plastic pipe is plumbing scissors. Cutting with such scissors can be easily controlled, and the process itself does not require much effort. This method allows you to properly cut the pipe along. Scissors are designed for cutting pipes with a diameter of no more than four centimeters.

For cutting pipes having a large diameter, other tools are used. For example, masters often use a grinder.

When processing such pipes should follow some recommendations:

- Always use a disc that is designed for processing metal products.

- when cutting, do not press the tool hard.

Truborez for steel pipes

When using pipes of steel of different diameters, craftsmen often encounter difficulties during their fitting and cutting. In this case, a specially made pipe cutter works best. Before buying a tool, it is advisable to study the nuances of all types of such ready-made devices.

The first thing you need to pay attention to is the diameter of the pipe and the material for which the tool should be designed.

There are three types of cutters:

- for thin-walled pipes;

- for ceramics;

- for very large amounts of work.

It is important to note that only electric torches are designed for heavy loads. The work of such tools is almost completely automated. They can cut pipes of cast iron or steel, having a diameter of up to three hundred millimeters.

Consider the basic professional mechanisms for cutting, differing features and design.

- Roller pipe cutter is used for cutting steel products. The scheme of this tool includes groups of rollers. Some carry out the cutting of the material itself, while others are designed to guide the pipe during operation. Roller pipe cutter, having in its design one roller,can cut products up to fifty millimeters in size.

- A pipe cutter cuts plastic pipes with a diameter of up to one hundred millimeters. Such a cutter looks like a cage made of steel with discs adjustable for the desired diameter. These same discs is the cut itself.

- Chain pipe cutter. This tool is used very rarely, because it is designed exclusively for cutting fragile ceramics or concrete.

Also pipe cutters are divided into manual, electric, hydraulic and pneumatic.

- Manual pipe cutter is easy to operate. To make a cut with this tool, you need to strengthen the apparatus on the pipe in the right place and take a few turns with the handle or the pipe cutter itself. One of the main advantages of handheld cutting equipment is easy control of the entire process, since the cut is the result of the physical effort you control. The disadvantages of such cutters are the physical fatigue of the master with a large amount of work and a small diameter of the pipes being cut.

- Using an electric cutter, you can complete high volume work in a fairly short time.The advantage of this cutter is a very high quality of materials used in its production. The strength of this tool will allow you to repeatedly perform numerous actions on cutting, without worrying about the wear resistance of the tool. Of the advantages of this device can be noted also the ease of cutting performed by an electric motor. The disadvantage of such a tool is practically only one - the high cost of the cutter. Therefore, such a purchase for one-time work is inappropriate.

- Pneumatic pipe cutters use compressed air injected into the working piston for their work. Tools of this type are used when cutting pipes having a diameter of up to one hundred thirty centimeters. The process of cutting is done by incisors.

Such pipe cutters handle pig-iron equipment well.

For cutting pipes also used milling machine. Waterjet cutting is one of the fastest and most effective ways. Metal processing is performed by a jet of liquid, which emerges from a special nozzle with high speed and pressure.

Angle cutting technology

The choice of the method of cutting the pipe depends on its diameter and thickness.Also, when choosing the cutting technique (at an angle or straight), it is important to take into account the material of the products that will be processed. For example, an aluminum pipe is much easier and faster to cut than products with thick walls. Plastic pipes of small diameter need to be cut at an angle with special scissors. You can control the cutting angle with a conventional protractor.

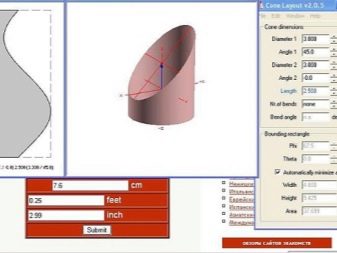

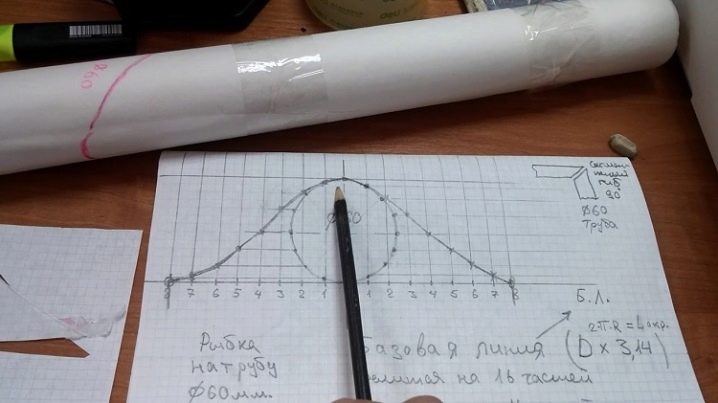

When calculating the cutting angle, special computer programs are used. Especially complex calculations are necessary for a 45 degree cut. After the calculations, it is necessary to create a template from paper or thick fabric. Such patterns are easily printed on the printer.

Cutting pipes on the patterns allows you to get a variety of angles.

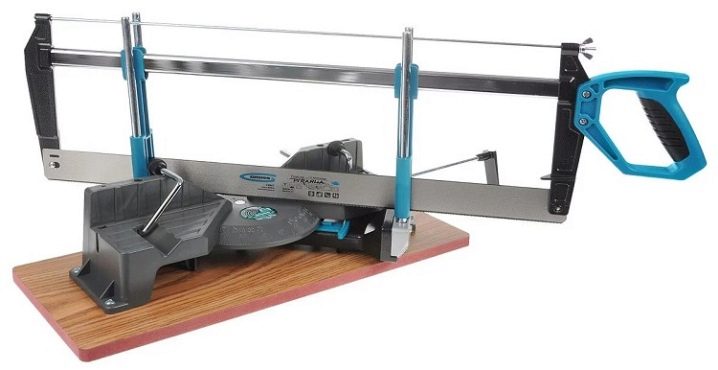

Cutting bar

Stulo is a simple tool that is used in everyday life. It is also well suited for cutting pipes. You can buy a block, or you can make it yourself.

To do this, take a board made of wood, equal in width to the diameter of the equipment being cut. The length of this board should be five hundred millimeters. Also take an additional two boards of equal size.They must be wide by a size larger than the width of the first board.

From these boards, assemble a structure that is shaped like an inverted “P”. Below you need to install the main board. In the center of the future mollusk it is necessary to mark a rectangle, its sides should be directed inside the boards located on the sides of the structure, passing along their borders.

Divide the resulting rectangle by the diagonals. Then, along the lines that you get on the sides of the upper edges, cut the boards to their base. So you make a template for cutting at an angle of forty-five degrees. Protractor, you can mark any angle, and then make a cut.

Other methods and tools for them

Gas equipment

Cutting gas pipes is always accompanied by a high level of danger, because gas has a tendency to ignite from any spark. When cutting pipes grinders create ideal conditions for an explosion. Take this issue with great responsibility.

Use sparkless pipe cutters.

Cast iron equipment

As with any other metal, cutting iron methods are divided into mechanical and thermal. The choice of tool depends on the design features.Equipment that cuts cast iron: angle grinder, pipe cutter, chisel, jigsaw, plasma machine, hacksaw, gas cutters. The pneumatic pipe cutter described above is best suited.

Thin-walled equipment

Thin-walled pipes are best cut with a single-roller pipe cutter.

Large diameter

Cutting a large-diameter pipe with a hand tool is quite difficult, and sometimes impossible at all. To simplify the cutting of this type are used almost fully mechanized methods, or methods of thermal effects on the metal.

In this case, you can use for cutting:

- battery cutter;

- guillotine pipe cutter;

- pipe cutter with rollers;

- special scissors.

Cut right along: the nuances

The most important point in ensuring high-quality pipe cutting is the selection of the right tool.

- Jigsaw. With it, you make a neat cut. You do not need special equipment.

- Bracelet with a slit. It is very convenient and allows you to perfectly perform the work.

- File. When used, the incision is also qualitative and even.But keep in mind the fact that working with a file will take a lot of time.

- Bulgarian. With this tool you cut the pipe quite quickly and easily. But the cut will not be too smooth.

Recommendations of specialists

With the usual markup, you can accurately calculate the cut angle in simple cases. And turning to software calculations, you can with very high accuracy cut metal and plastic at non-standard angles. Preparation and calculations will allow to precisely cut off any pipe.

It is worth remembering that the fitting and welding connections need to be cut exactly at ninety degrees.

You can find out how to cut a metal pipe using a pipe cutter with your own hands from the video below.