How to choose and install a copper pipe for air conditioning?

Demand for air conditioners is growing every year. Particularly popular are split systems. They work quietly, but their efficiency is high. For the installation of this equipment requires a special and careful approach.

These systems include many elements, respectively, and the demand for consumables also increases. Each of the parts performs its specific important function. One of these components is a copper pipe for air conditioning.

Special features

Copper is the optimal material for the manufacture of pipes, because this metal is the most resistant to the corrosion process. Usually, this element must be purchased independently, because it rarely enters the ready-made set.A wide range of these products will allow you to easily choose the most suitable option.

Copper pipe has the ability to withstand high pressure, and, accordingly, strength and ductility. Also, copper is resistant to temperature fluctuations, exposure to oxygen, sunlight and does not react with many refrigerants. And as a result of interaction with chlorine, which is contained in refrigerants, immediately after the start of operation, a protective layer is formed on the inside of the pipe.

The temperature range of use of pipes made from this non-ferrous metal varies from -200ºC to + 300ºC. Another feature of the material is that it has the ability to destroy harmful bacteria, so it can be used in systems with drinking water.

The low weight of this part contributes to easier installation and operation. Copper has more than 20 varieties, but in any case it has a number of advantages over aluminum or plastic, despite the higher price. The service life of products reaches 100 years, which means that the use of such pipes very quickly pays off.

Aesthetics - also their significant advantage.It is worth noting that at the ends of the finished pipes there are plugs that prevent exposure to dust, insects, and everything that may interfere with proper operation.

Pipes are produced in two main types:

- annealed (soft);

- unbaked (solid).

The former are distinguished by sufficiently high flexibility and low tendency to deform For air conditioners use exactly annealed models, because they are more elastic and easy to install.

Dimensions

Choosing the right diameter of copper construction is the key to maximizing equipment performance. The discussed part is used to connect two units of air conditioning systems and it is needed in different diameters. Most often in household split-systems, which are installed in apartments and houses, use 2 freon highways with an internal section in inches 1/4 (this is 6.35 mm) and 3/8 (9.52 mm). Also in some cooling systems, pipelines are used with diameters in 1/2 inch (12.7 mm), 3/4 (19.05 mm), 5/8 (15.88 mm).

The performance of air conditioning systems primarily affects the choice of this part, since the higher it is, the larger the diameter of the pipe must be.

This is due to the fact that in more powerful models more refrigerant passes through the pipes.

- Air tube size 1/4 inch often used in split systems. Its main advantage is the price-quality ratio.

- The 3/8 inch part is mainly mounted in air conditioners that work in rooms of less than 35 square meters. m. And the size of 1/2, on the contrary, - more than 35 square meters. m

As you can see, the dimensions are in inches according to GOST. For more understanding and convenience, you need to pay attention to the following table.

Diameter in millimeters | Diameter in inches |

6.35 | 1/4 |

9.52 | 3/8 |

12.70 | 1/2 |

15.88 | 5/8 |

19.05 | 3/4 |

When designating the size of the pipe refers to the outer diameter. The optimal wall thickness of the pipe is considered to be 0.7 mm.

Installation

The laying of copper pipes has certain nuances, so this technology can be divided into the following steps:

- track marking;

- wall shaving, if necessary;

- directly laying the track.

And in order to proceed to the installation of pipes, you need to perform the following steps.

- Determine their size, that is, length. The distance between the connected units of the air conditioner should be increased by about 0.5-1 m, then the connection will be carried out correctly.

- It may happen that the part is more or less than the required length.In the first case, the pipe should be cut with a special tool (pipe cutter). He allows to receive very equal edge of a cut, not such as would turn out from a hacksaw. If the length is less than the required, then the spike of several pipes or their connection is carried out using fittings.

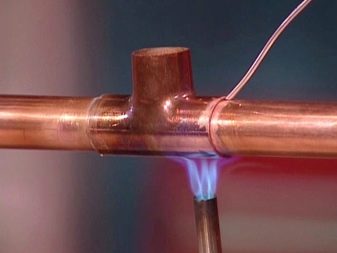

Let us consider in more detail both versions of the installation. In the case of soldering, you need to pay attention to the absence of dust and other foreign particles, as they affect the performance of the entire system and can damage it. It is necessary to pre-clean and degrease air conditioning pipes. As the solder is usually used standard materials - tin or compounds with a proportion of silver.

Soldering provides a fairly solid connection, and the installation itself will be quite inexpensive.

PThe soldering process is the following sequence of actions:

- the working surface is cleared and degreased;

- verifies the correct location of the fastened parts;

- from the outer part of the compound flux is applied in a very small amount;

- the junction is heated to the required temperature;

- solder is applied and evenly distributed;

- Flux residues are removed as carefully as possible.

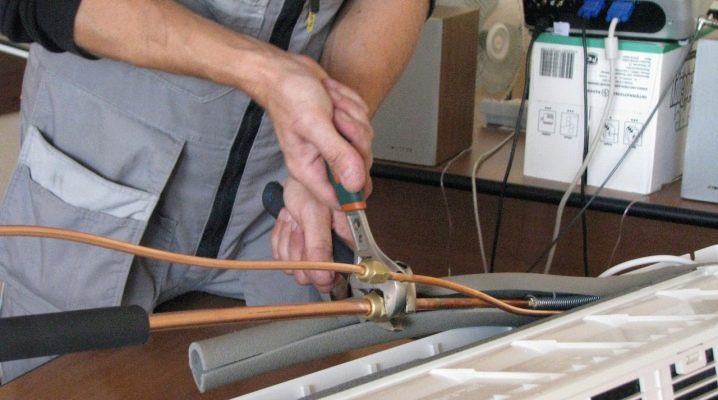

Connecting pipes with crimp fittings is simpler and easier. As a rule, fittings are made of brass, in conjunction with copper, this connection will be protected from corrosion and oxides. Fittings can be of various shapes - angles, couplings, tees, etc. This makes it possible to make the pipeline configuration as optimal as possible.

Such a connection is very convenient, but less reliable, since the nut can “loose” during operation. Fitting connections should be made in places with easy access to assess the condition of the structure.

Fastening fitting produced by the following technology:

- to begin with, the ends of the pipe are very carefully cleaned;

- they are consistently put on the nut, crimp ring, the fitting itself;

- the latter is held in one position with a wrench;

- the nut is threaded onto the thread of the fitting using another wrench.

The density of the compound is very important. In this case, it is achieved due to the fact that the compression ring is pressed tightly over the entire diameter of the pipe. One of the advantages of mounting this method is that, if necessary, the connection can be easily disassembled and reassembled.

Flaring the ends of the copper tubes plays a very important role in the operation of the air conditioner and protects the entire system from leaks. It is produced with the help of special equipment - rolling and a small vice. This is done in order to install nuts on the ends of each copper tube. In addition, it is necessary to have fittings, but, as a rule, almost all variations of air conditioning systems have them in the connection points.

The procedure for flaring is as follows:

- the return nut must be put on the end of the pipe;

- clamp it in a vice, leaving the pipe a little sticking out;

- sort out the end and compare with the results in the table below.

Diameter of pipe, mm | Height mm | Diameter of cutting, mm |

6.35 | 1.0-1.3 | 8.3-8.7 |

9.52 | 0.8-1.0 | 12.0-12.4 |

12.7 | 0.5-0.8 | 15.4-15.8 |

15.88 | 0.5-0.8 | 18.6-19.0 |

19.05 | 0.1-0.5 | 22.9-23.3 |

Tips

- Consider how to cut copper pipes. It is very important accuracy and accuracy. For this, as mentioned above, you need a pipe cutter: at the very end you need to install the pipe and slowly begin to rotate in the opposite direction from the stroke. As a result, the cut angle should not be more or less than 90 degrees.

- If soldering is used for pipe installation, then it is very important to observe the temperature conditions during soldering and to ensure adequate ventilation of the room,as cadmium vapor and fluoride released during heating can be hazardous to health!

- When using the option of connecting copper pipes with fittings, the most important thing is to thoroughly clean their edges from burrs.

- In the process of tightening the nut when installing the crimp fittings, it will be enough to stretch it 1-2 turns from the initial stop.

- In order for the pipeline not to freeze or not overheat (in other words, to create insulation), it is sometimes placed in a special sleeve that is made of polyethylene or foamed rubber. It also increases the energy efficiency of the structure.

Installation of copper pipes can be carried out independently, the most important thing is to correctly approach this issue, to study a sufficient amount of information and advice, then unwanted problems can be easily avoided.

For how to install the air conditioner, see the video below.