Types of pipes: scope and variety of materials

Pipes are elements used in the installation of pipelines of various types. The modern market offers a huge variety of pipes, differing in such characteristics as dimensions, materials, scope of use and other parameters.

Classification by purpose

Plumbing

The name of this group speaks for itself. Water pipes are used for the installation of water structures, the purpose of which is the delivery of drinking water to the consumer. For the production of elements of the company use a variety of materials with a variety of performance characteristics.

All the options currently available on the market can be divided into variants with regard to the material.

There are three groups of pipes:

- plastic;

- metal-plastic;

- metal.

The first two classes enjoy greater popularity and distribution. Metal products are gradually inferior to more practical and modern materials, but plastic can not completely extrude metal from the market and vice versa, due to the fact that each option has certain individual characteristics.

Pipes of metal, in turn, are divided into groups depending on the raw materials. Specifications depend on it.

In production it is used:

- copper;

- steel;

- cast iron;

- aluminum.

For the manufacture of plastic plumbing products used special compositions:

- polybutylene;

- polypropylene;

- polyethylene;

- polyvinyl chloride.

High-quality pipes attract buyers with a favorable price, ease of installation, wear resistance, long service life and practicality.

Sewer

Currently, for equipment of sewage systems of various types, products made of cast iron and plastic are used. Each material used in the manufacture has its own advantages and disadvantages.

Pipes of this type are also divided into groups of strength:

- Lungs. Elements are suitable for placement at shallow depths.

- Average.Pipes are used for arranging sewers under the carriageway with a small load.

- Heavy. This class is applied on the basis of industrial facilities and for installation under highways.

Laying sewer pipes takes a long time. After the preliminary marking, it is necessary to place the fasteners and assemble the finished units. You can proceed to installation only after checking the connections and the correct location. In the process can not be used bell-shaped connections between the floors.

Proper installation will provide practical use, as well as easy cleaning and replacement of components when necessary.

Gas pipelines

The gasification process requires special treatment and reliable equipment. Using poor quality pipes and impractical connectors can cause accidents. Due to the high risk of the pipeline installation process, only highly qualified specialists can be involved.

The basis of a safe and practical gas pipeline is a pipe.

In this area, elements from such materials are used:

- steel;

- copper;

- polyethylene.

Steel elements of gasification actively used in the Soviet era.In spite of the fact that more practical and modern versions have come to their place, steel pipes continue to be used for external and intra-house networks. Products can be safely operated in regions with unstable climate. They have excellent resistance to sudden changes in temperature. In the production of pipes used low carbon steel with a low content of fluorine and sulfur.

There are two types of gas pipes from steel:

- seamless seamless;

- welded elements with a longitudinal straight or spiral seam.

Copper pipes can be used for arranging low pressure pipelines. Installation is only allowed using press fittings. The product is marked with a special yellow marking and a sealing ring of the same color.

Modern manufacturers in the manufacture of gas pipes use special low-pressure polyethylene. The material has all the necessary performance characteristics for laying large highways. Products made of HDPE are recommended for use for gas pipelines under pressure up to 1.2 MPa.Quality pipes can boast excellent reliability and durability.

Drainpipes

One of the varieties of pipe rolled is a drainpipe. The task of such elements is to drain excess moisture from the roof. Drainage systems, in addition to the direct destination, protect the building from moisture, resulting in increased service life of the building. It is necessary to approach the choice of drainpipes responsibly.

Regardless of the material of manufacture, to drain pipes make serious demands. To perform the functions assigned to them, the elements must have excellent resistance to moisture, practicality and durability. Due to the fact that the drainage systems are installed outside the building in front of everyone, the details of the design must have an aesthetic appearance.

In the manufacture of drainpipes using various materials.

More details on the most popular options:

- Drain of metal. Despite the fact that the metal is susceptible to corrosion, this material is used to manufacture reliable drain pipes. A special protective layer that is applied to the product will protect it from destruction.When processing is used zinc and polymers. Pipes of this type can boast a long service life.

- Plastic items. Products of this type are very popular, which continues to grow. The main advantage of such systems is absolute invulnerability to corrosive processes. It is also necessary to note their light weight and low noise.

- Copper drain. Great for arranging drainage systems, but because of the high price they are rarely seen. When interacting with water, a strong film is formed on the copper, called patina. It provides additional protection against damage and destructive environmental factors. Copper pipes have a long service life and look great.

Drainage

For the well-coordinated work of the drainage system, it is necessary to choose high-quality pipes that have all the necessary characteristics. The feature of the elements is special holes, due to which the pipes can collect excess moisture from the soil. The task of the pipes is to filter, collect and divert excess moisture outside the land.

Requirements for drainage pipes:

- resistance to sudden temperature changes and internal fluid pressure;

- excellent mechanical strength;

- the ability to drain water in any volume.

Drainage pipes are divided into different categories depending on the characteristics.

There are two types of pipes on the structure:

- Single Layer. Elements can have a smooth or corrugated texture for increased flexibility, strength and water grip area.

- Biaxial. Improved version. Pipes have an inner smooth wall and a corrugated outer sheath. Textured shell increases resistance to stress and impact.

Depending on the type of construction, there are two classes:

- Flexible. For the manufacture of used polymers. As a rule, they are used for surface mounting.

- Hard. The class is divided into two categories: thin-walled - diameter from 5 to 15 centimeters, and thick-walled - pipes for deep installation in the territory of locations with possible displacement of soil layers.

For the manufacture of drainage pipes use different materials:

- reinforced concrete;

- metal;

- ceramics;

- plastic;

- asbestos cement.

One type of building metal products are shaped pipes. Elements can have an oval, square, flat oval or rectangular section. Greater popularity has gained the last two options. Low-alloyed and carbon steel is used as the base material. Some companies make stainless steel products on request.

The main feature of pipes in this category is excellent bending resistance. In the construction industry, such elements are used for special constructions. Currently, metallurgical industry specialists are engaged in the production of many types of shaped tubes, differing in size.

The minimum cross section for products of this type is 10x10 mm. The maximum can reach 450x350 mm. The length of the elements varies from 6 to 12 meters. The range can also be varied. In the manufacture of professional pipes manufacturers adhere to specially developed standards GOST.

Profile pipes are used to make metal constructions. In this case, parts can act as decorative, loadable and loadable decorative elements.

Materials

For the manufacture of pipes using different materials depending on the purpose of the elements.

Steel

Steel pipes have been used in various fields for a long time, but, despite the development of modern analogues, they are still in demand. The material itself is vulnerable to corrosive effects, and therefore manufacturers use a special protective coating (zinc layer). Steel pipes are seam and seamless.

Products are divided into the following groups:

- welded;

- galvanized;

- profile;

- cold drawn;

- hot rolled;

- cold rolled

Installation of steel structures is a complex and lengthy process that requires the participation of classified specialists.

Steel pipes are also divided into groups due to the type of section:

- rectangular;

- polygonal;

- square;

- round.

To connect the elements together, use the welding method, thread or special couplings. High-quality steel pipes demonstrate excellent resistance to high pressure.

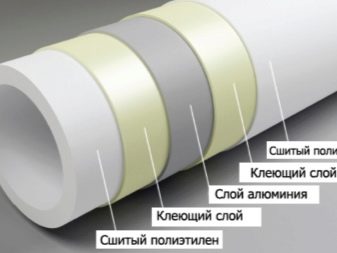

Metal plastic

Experts from the construction and industrial spheres note that the popularity and prevalence of plastic pipes is growing day by day.Products have excellent performance characteristics (wear resistance, practicality, durability), and installation is simple, easy and does not take much time. You can assemble the pipeline yourself, without the involvement of specialists. All that is needed is the material itself and the necessary tools.

As drawbacks, a possible leakage at the joint site, as well as low heat resistance, is noted. Such designs do not apply to fire-resistant communications.

The main feature of metal-plastic products is that the pipes consist of several layers. During operation with sudden temperature fluctuations, they may begin to delaminate.

The operating temperature range for pipes of this class is 80-100 degrees Celsius above zero.

Elements are used for arranging pipelines of various types:

- for floor heating;

- cold and hot water pipes;

- heating systems.

The service life of products ranges from 30 to 35 years. Metal pipes can boast excellent corrosion resistance and increased resistance to aggressive chemical elements.High strength is ensured by the metal layer.

Most often for the connection of elements use special fittings, which are divided into two groups: press fittings and threaded. Experts recommend making a choice in favor of the first option. In practice, it demonstrates greater reliability and practicality.

Copper

Copper water systems are considered the most expensive. Because of this characteristic, they are much less common than other options.

Among the main advantages are:

- long service life (from 50 to 100 years);

- esthetic appearance;

- anti-corrosion properties;

- resistance to temperature changes (wide operating temperature range from 200 degrees below zero to 250 degrees C with a plus sign).

In addition to the high cost, as minuses emit low strength. Rough handling can damage the mold.

Due to the presence of more profitable counterparts on the market, copper pipelines are mounted mainly to achieve a special external effect. For example, when arranging spillway systems.

In the process of installation it is necessary to take into account that the material is incompatible with connecting parts made of other metals and alloys. For copper pipes, purchase the same fittings.The construction of the pipeline from copper elements is an expensive and complicated process. Component parts to find is not easy. In most cases, you have to make an individual order.

Cast iron

Cast iron pipes are resistant to rust, but they are inferior in strength and practicality to steel products. Also noted are advantages such as durability and resistance to temperature fluctuations. Among the disadvantages emit a large weight of the structure. At installation it is necessary to use reliable and strong fastenings.

Cast iron pipes are used for arranging sewer systems, heating utilities and plumbing. To improve corrosion resistance, pipes are treated with butyme or varnish.

Currently, manufacturing companies produce three types of pipes that differ in strength level:

- Black cast iron. Products have a rough texture and good strength.

- Gray. More advanced alloy.

- VCHSHG. Elements of high-strength nodular cast iron. This is the most practical and durable option. Their service life varies from 20 to 50 years,and the diameter of the pipes is from 5 to 100 sentiments.

By type of connection, cast iron pipes are divided into:

- pipes, joined by staking;

- bell-shaped

The advantages of cast iron pipes:

- alloy resistant to corrosive process;

- environmentally friendly material;

- resistance to fire and aggressive substances;

- cast iron withstands long and heavy loads;

- excellent wear resistance;

- noiselessness (in the process of using practically do not emit sounds);

- self-cleaning capability due to optimum diameter.

In addition to many of the above advantages, cast iron pipes have minuses. The installation process of such elements is complicated. It requires special knowledge and accuracy. To install the products you need strong and reliable fasteners due to the heavy weight of the pipes.

Another disadvantage is the high price compared to plastic parts.

PVC pipes (polyvinyl chloride) are used in a variety of areas, including drainage systems, sewage and water pipes. This is a common product with several advantages. The maximum working temperature is 90 degrees Celsius. The diameter is from 1.6 to 50 centimeters.When arranging hot water systems choose pipes with a cross section of 16 to 50 millimeters.

The pressure indicator that PVC elements can withstand is from 6 to 46 atmospheres.

Among the positive qualities are:

- simple and quick installation;

- affordable cost;

- rich assortment due to the prevalence and popularity of the product;

- resistance to fire;

- service life - up to 50 years;

- excellent frost resistance;

- the inner surface of the elements is resistant to chemical elements;

- high strength;

- corrosion resistance.

All the disadvantages are due to the fact that plastic pipes are in many respects inferior to cast iron pipes. In the process of connecting parts using special fittings.

Aluminum

Aluminum is a lightweight and affordable material that has taken its place in the production of pipes. Pipes made of this metal are considered one of the most common aluminum profiles.

For the arrangement of various systems and structures are actively used round aluminum pipes.

Elements have such positive characteristics:

- low weight;

- esthetic appearance;

- reliability;

- invulnerability to corrosive processes;

- long period of service;

- easy operation.

In the industrial sphere, the popularity of round aluminum pipe is increasing. Affordable cost has played an important role in the development of product popularity.

The scope of use of aluminum elements is wide:

- furniture making;

- construction industry;

- equipment of advertising structures;

- collapsible and easily mounted structures;

- cooling systems;

- decorative designs;

- water and gas drainage systems;

- production of spare parts for industrial machines and machines of various kinds.

Sizes and shapes

All commercially available pipes are divided into classes according to shape and size. First of all, the elements are divided by diameter.

There are three groups:

- Small The dimensions of the cross section count from 5 millimeters to 10.2 centimeters.

- Average. The indicator varies from 10.2 centimeters to 42.6 centimeters.

- Large. Products with a cross section above 42.6 centimeters fall into this category.

Another factor that you must pay attention to when buying is the throughput of the pipe. It directly depends on the diameter of the element, as well as the texture and structure of the inner walls. Also the number of bends in the pipeline system affects throughput.The length depends on the use of the pipe.

The shape of the pipe is divided into two categories:

- round;

- profile

Connection methods

There are many ways to connect pipes. The methods depend on the material of the elements, diameter, scope and conditions of use, as well as other aspects. Many manufacturers in order to facilitate the process of installation and fixation of pipes produce sockets. They are equipped with solid and fixed rubber rings. This element increases the strength, reliability and tightness of the connection.

All methods of connection for plumbing pipes are divided into two types:

- Non-detachable. The peculiarity of this option lies in the fact that when the elements of the pipeline are disconnected, the integrity of the fastening and the pipe itself collapses.

- Detachable. The second method is divided into two subspecies:

- Flange clutch. This technique is used for the installation of PVC pipes. For work the pig-iron fixture with laying from rubber is used.

- Coupling. This technique is used only during the repair work of the pipeline, as well as to connect non-pressure and pressure pipes.

Welding

The welding method is one of the most widespread and popular due to its reliability and practicality.

Currently used two methods of welding:

- Handle.In this case, in the working process, it is necessary to simultaneously melt the outer surface of the smooth end together with the inside of the socket. If the work is done correctly, the elements are quickly and easily fastened.

- Butt. The master adjusts the ends of both tubes. Coupling of parts is carried out with the application of pressure.

The welding process involves certain difficulties that only a professional can handle. It is necessary to know not only the methodology, but also to be able to use specialized equipment.

In case of lack of experience, contact a specialist. The work carried out by the master, is the key to a long period of service and smooth operation.

Arc and gas welding

The most common methods of electric welding are gas and arc techniques, but before work it is necessary to carry out special training. The connecting elements are washed with caustic soda and warm clean water. Also need a solvent. At the place of welding, the edge processed by the solvent is cut off.

The principle of operation of gas welding equipment is that in the process of burning a powerful column of flame is formed,melting material when exposed to high temperatures. This method is suitable for coupling polymer and metal pipes.

Connection by arc welding is characterized in that the process takes place using consumable or non-consumable electrodes. When using the second option is used filler material.

Pasting of pipes

To date, such a one-piece bonding method as adhesive bonding is widely used. For work special compositions are used. The technique is simple and easy. It is enough to carefully treat the edges of the elements with composition and securely connect them with each other.

The main advantage of this technique is that after sizing the system can be used after a short time period. In the building stores you will find a huge range of adhesive solutions, designed specifically for arranging drainage systems and other similar structures.

Connection of products from various materials

To assemble the construction of pipes that differ in material of manufacture, use special elements: fittings, adapters and seals.They are recommended to be purchased simultaneously with pipes in specialized stores.

How to connect pipes from different materials, see the following video.