Characteristics and installation process of HDPE pipes

In the modern world, a properly installed heating system is a guarantee that in a country cottage or apartment it will always be warm and comfortable, and residents, even in extreme cold, will be able to feel protected from weather conditions. The use of advanced materials, among which the HDPE pipe, makes it possible to guarantee the long and stable operation of any heating or plumbing system.

Special features

Responsibility for the durability and operability of the heating system lies on the pipes, which provide a direct connection of all parts and parts. Therefore, it is necessary to treat their selection with full responsibility, because it is on this that the serviceability and service life of heating equipment depends.

In recent years, the use of low-pressure polyethylene pipes has become one of the most effective solutions for building heating or plumbing systems. They are distinguished by a huge number of advantages compared to other analogs that are on the market, but at the same time, some technical features should be taken into account before starting their direct use.

Pipes in the production process of which such materials were used are used to equip water supply systems, including drinking water.

The fact is that these pipes have a number of unique characteristics, among which are the following:

- First of all, they do an excellent job with cold weather conditions, and the maximum allowable temperature level for production work does not exceed 20 degrees. This makes them an excellent choice of cold regions of the country.

- They are characterized by impressive flexibility and the ability to change shapes, which makes it possible to provide resistance to kinks. When the liquid freezes, they expand, and when they thaw, they return to normal.Unlike other options, they do not crack and do not require replacement.

- Masters advise to resort to the use of PND pipes when the temperature of the liquid inside is not more than 40 degrees Celsius.

HDPE pipes are distinguished by a number of strengths that qualitatively distinguish them against the background of other varieties designed for heating systems. However, these products are also not deprived of certain disadvantages that you must pay attention to when buying.

Thus, the main positive aspects of the use of such pipes include:

- Durability. HDPE pipes do not lose their performance properties and can be used for 50 years or more.

- Resistance to corrosion and various chemicals. Due to these characteristics after laying the HDPE pipes do not need to be serviced, even if they are laid deep underground.

- The affordable cost of this pipe is not inferior to others in its properties, but at the same time they can boast a lower price.

- Not subject to scale formation. The inner surface of the pipes is very smooth, so there is no accumulation of scale and dirt.In addition, due to this property, the diameter of the pipe does not change during the entire lifetime.

- Low level of thermal conductivity, which ensures the absence of condensate on the upper surface of the pipe.

- Do not lose their properties in cases where the liquid freezes. If water suddenly hardens inside the HDPE pipe and turns into ice, the pipe will not lose its properties, but will simply begin to stretch to the required amount, and when the onset of heat returns the same dimensions again.

- By its mass, HDPE pipes are much lighter than steel versions, which significantly simplifies the process of their transportation and installation.

Despite the huge number of advantages, HDPE pipes are not without drawbacks, which should be paid attention to before buying. First of all, we are talking about not enough high technological properties. Such pipes in this context lose the steel and cast iron versions. In addition, they need special installation technology, which will require the involvement of specialized equipment and tools.

HDPE pipes can not boast resistance to ultraviolet rays, so they can be installed only underground.In direct sunlight, they lose their performance.

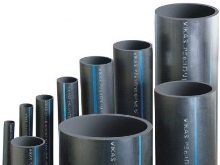

In addition, according to GOST, these pipes should have some features. For example, the delivery form for pipelines can be as whole segments or coils. And straight stretches are best used for large diameter pipes whose length is more than 5 and less than 24 m.

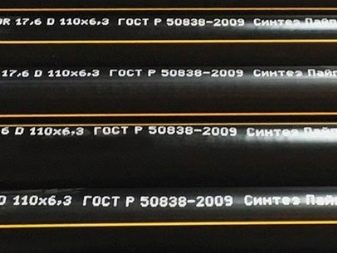

In addition, GOST establishes the brand of polyethylene, which can be used to obtain the pipe, as well as the diameter and thickness of the walls. The diameter should be greater than 10 mm, and the wall thickness should be no more than 20 millimeters. Such indicators can withstand even high pressure.

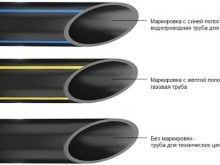

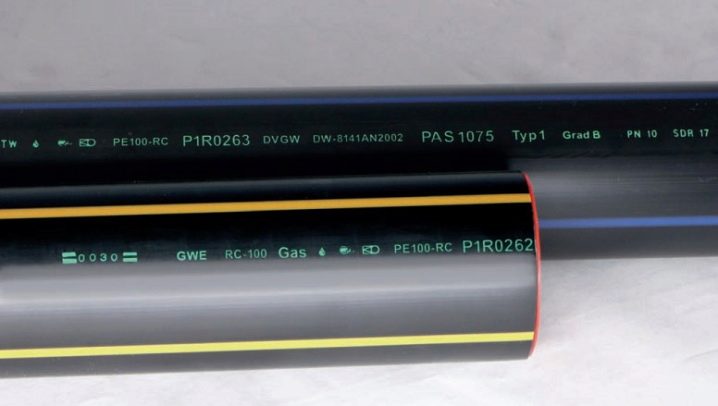

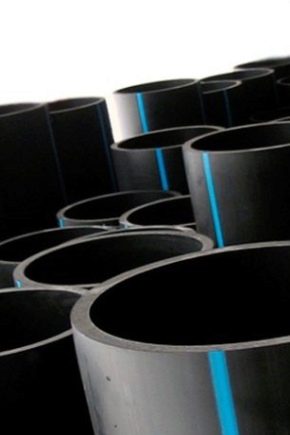

According to GOST standards, there should not be any visible defects on the product. The color of the pressure pipe can be either black or black with blue stripes, which must be at least 4. Special requirements are imposed on the HDPE pipes used for the gas pipeline network. The permissible diameters in this case fluctuate around 16-630 mm, and the color may be yellow or black with yellow stripes.

Installation

In order for HDPE pipes to fully perform the functions assigned to them, it is necessary to competently and responsibly approach the installation process.The ability to handle the loads and their durability depend on the installation.

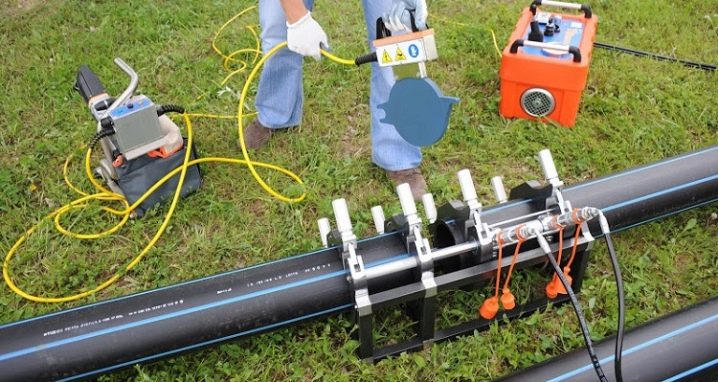

To date, there are two ways to connect low pressure pipes: detachable and one-piece. The essence of the first method is to use fasteners, and in the second case, a welding machine or electrofusion welding is used. One-piece connection is popular when working with high-pressure pipes, as this method of connection allows you to cope with huge loads. But for low pressure polyethylene pipes the ideal solution is a plug connection.

In addition, in some cases it is necessary to carry out butt-welding. To carry out this method of installation will not work without the involvement of a special apparatus. The essence of this method of installation is to heat the polyethylene and strongly compress the pipes between them.

Careful attention should be paid to cleaning the joints, as the ingress of dirt can disrupt this process. You also need to closely monitor the temperature, because in no case can the material be melted down.otherwise its tightness will be affected.

The distinctive advantage of a detachable connection is that it allows you to disassemble pipes, to carry out their reconstruction or repair work. That is why this method of connection is very popular in the construction of private suburban areas, to create watering systems and so on.

In addition, some resort to this method due to the lack of a welding machine, and during the installation process, special couplings are used that ensure the reliability of the segments being joined.

Detachable connection can be carried out by several methods, among which are the following:

- use of compression fittings, due to which it is possible to achieve high elasticity of the finished pipe and its tightness;

- fitting and flange methods, the essence of which is to use fasteners.

For installation in a detachable way there is no need to use additional parts and elements. You only need the key in order to tighten the clamping nuts and parts. It should be noted that this method is only suitable for pipes whose diameter does not exceed 35 mm.The use of special threaded connections eliminates the use of a welding machine for connecting low pressure polyethylene pipes.

For professional installation, you must use a welding machine and specialized equipment. Welding allows you to achieve maximum tightness of the seams, and you will not have to put a lot of effort into it. A distinctive feature of this method lies in its simplicity, as well as the possibility of automation.

The second most popular is the use of electrofusion welding.which is designed for low pressure polyethylene pipes, and can also be used for polypropylene options. In this case, the installation is carried out through the use of a fitting and its apparatus. The tightness of the seams during installation can be achieved thanks to the compression fitting. After the pipes are completely cooled, they can boast of reliability, durability and durability.

In the process of installing the HDPE most often the following errors are made:

- Very often, many people forget that it is necessary to make a linear expansion of the pipeline with their own hands.As a result, a high voltage is created during their operation, which has an impact on durability.

- It is extremely important to correctly determine the distance between the fasteners, and then connect the parts. If at this stage to make big mistakes, the pipeline begins to sag during use, which also adversely affect the service life of the entire system.

- In no case should the pipe be cemented without additional insulation.

- Insulation is also necessary if the product will be used for cold or hot water supply. If this rule is violated, then condensate will appear on the walls of polyethylene pipes.

People usually do not comply with the welding conditions, which has a negative impact on the reliability of the system. and may disable it in the future. Thus, the installation of low pressure polyethylene pipes can be done independently, however, it is necessary to follow the instructions clearly, to use quality materials and components.

Only in this case, it is possible to install pipes that can boast reliability and durability, as well as be able to serve for a long time.

Scope of application

Like other pipes, polyethylene applications are due to their physical properties. A distinctive feature is that they can boast the most impressive resistance to mechanical damage, so that they can be used not only in the process of arranging the sewer system, but also to ensure the protection of cable lines.

Pipes for pressure pipelines can be made of this material.that can cope with high pressure and loads.

A significant disadvantage of this type of polyethylene is its inability to withstand high temperatures. When it reaches 80 degrees, the material loses its properties, and at 100 degrees it actively melts. In the process of using polyethylene materials should be repelled from this circumstance.

It should be noted that even despite this drawback, the areas of use of HDPE pipes are extremely extensive. They are actively used for watering systems, water supply, well construction, etc.

As with any product, a number of requirements are put forward for HDPE, including:

- Requirements for storage and transportation, so it is necessary to take into account the factors of vehicle safety and have the appropriate licenses for labor protection.

- When creating and using a material, no harmful substances should be emitted into the atmosphere. This circumstance is extremely important, since the HDPE pipe is very often used to transport drinking water.

Kinds

On the modern construction market there is a huge amount of HDPE materials, which are divided into groups according to the characteristics of their purpose and the ability to cope with loads of various sizes.

To destination

Low pressure polyethylene can be used for the following purposes:

- Plumbingdiffering in color. They are either blue or black with blue stripes. If pipes are used to transport drinking water, then special requirements are put forward for their production. In addition, hot water pipes are available.

- Gaswhich are distinguished by a yellow color scheme. They can be not only completely yellow, but also black with yellow longitudinal stripes.

- Sewer, a distinctive feature of which is that they can be used for both in-house and external sewage. Such options differ in the built-in sockets. Unique performance properties allow you to use them in conventional systems, and when creating reservoirs.

- Drainagewhich are designed to divert groundwater from the foundation and structures. Basically, they are created with a unique corrugated structure and are characterized by increased strength to mechanical loads.

- Irrigating, the essence of which is to sum up the water to provide the plants with the necessary amount of water.

- Casing pipe HDPE. Such products are used to create wells, to supply technical or drinking water. A distinctive feature of this pipe is that it is not afraid of natural decomposition or shifts of the earth.

- Technical. Used for transporting liquids that metal pipes cannot handle.

It should be noted that the HDPE pipes are supplied not only in the form of whole segments, but also in the womb in the coils.

By properties

A distinctive feature of low-pressure polyethylene is that this material boasts an impressive resistance to stretching and tearing. In addition, the material is famous for its flexibility and plasticity, so you can make pressure pipelines from it.

Among the most popular and sought after species are the following:

- Non-pressure, which have no requirements in the field of loads. Usually this option is used as technical pipes.

- Low-pressure, which differ in the ability to cope with large internal pressure.

- High pressure. A distinctive feature of such pipes is that they can withstand any pressure, and the wall thickness is more than 70 mm.

As for the external diameter of pipes, it can vary from 10 to 1500 mm and more, so that they can be used to transport liquids of any quality and type.

Among the most popular and popular on the modern market of HDPE pipes are the following:

- Pressure pipes, which are used for outdoor water supply.Such products are considered indispensable in the construction and repair of external pipelines that transport water for household or drinking use. In addition, the characteristics of the pipes allow them to be used for transporting liquid and gaseous substances. This is made possible by the fact that low-pressure pipes can cope with exposure to chemicals.

- PVC pipes, which are used as external water supply for water transportation. The only drawback of this pipe is that the temperature of the liquid in it can not be more than 65 degrees Celsius.

- Pressureless PVC pipes designed for the construction of modern sewage systems. Such products have performed well in the process of repairing underground systems and facilities for sewage disposal. Such pipes are available in a large number of segments and diameters, so you can choose the best option for any occasion.

- Profiled pipes, which are considered ideal for creating drainage and sewage systems.The main feature of the profiled pipes is that they are designed to operate at a temperature of not more than 70 degrees Celsius.

Dimensions and weight

Most often PND-pipes can be seen in black or blue color scheme. Manufacturers for good reason to paint products in such colors. The fact is that it allows them to be distinguished from other types of pipes. Sometimes blue stripes can be seen on the walls, which means that this pipe can only be used to provide cold water. If there are yellow stripes on the pipe, this means that it is intended to create a gas pipeline.

The diameters of the PND-pipes vary from 20 to 1000 mm. They have a small cross section and are used for water and heating systems in country houses and apartments. If you need pipes with a more serious section, which is 160 or more millimeters, then they can be used as risers of the water supply and sewage systems. It should be noted that products with large diameters are usually used in industry, but for private buildings and apartments a small section is enough.

For the manufacture of pipes low pressure polyethylene can be of different density. This can be understood with the help of numbers that stand after a special abbreviation.The durability of the product and its ability to perform all the functions assigned to it depends on this indicator.

In each store there are special tables that will help you choose the best option.

Manufacturers

One of the most qualitative and durable in the domestic market are PND-pipes from the company "Trubopolymer". Due to the fact that the production process uses exceptionally high-quality materials, the finished product boasts resistance to aggressive media and durability.

For arranging the plumbing system, the ideal solution will be products from the company. "Aqueduct"that can be used under the ground. Even with deep bedding, you will not need to carry out any maintenance work on PE-pipes, regardless of the region of use.

Thus, HDPE pipes are of high quality, reliability and durability. The right choice and installation ensures that the pipe will last for many years, fully fulfilling the functions assigned to it.

In addition, close attention should be paid to the selection.On the HDPE marking is indicated, which allows you to choose the appropriate option for the heating, gas or plumbing system.

In the next video, you will see how to assemble a fitting for a low-pressure polyethylene pipe.