Casing Installation Rules for Wells

The selection and installation of the casing is an important stage in the arrangement of the autonomous water supply system. This hydraulic structure requires reliable reinforcement. To improve the quality of the extracted resources and increase the life of the structure, follow the rules when installing casing for wells.

Special features

The selected casing for a well must meet certain requirements. For example, the standard for metal pipes is GOST 632-80.

State standard for asbestos-cement pipes - 539-80. Regulatory document, which mentions the parameters of plastic pipes - GOST 2248-001-84300500-2009. The choice of pipes from this material is complicated by the fact that, in addition to GOST, there are many varieties of technical specifications.

In addition, there are numerous foreign standards.In the matter of choosing one or another type of casing important knowledge of the advantages and disadvantages. Therefore it is necessary to understand the characteristic features in more detail.

The main advantages of metal products:

- high strength;

- the presence of a thread that allows you to create a sealed structure;

- service life up to 50 years;

- possibility of cleaning when silting.

Among the disadvantages of metal casing pipes it is worth noting:

- susceptibility to corrosion;

- rusty sediment in water;

- substantial weight of structures, which makes installation difficult;

- high cost of products.

Asbotsementny casing good qualities such as:

- resistant to the aggressive effects of salts;

- they are resistant to corrosion;

- safe and practical to use;

- have a long operational life.

In addition to the advantages, the asbestos-cement casing also has disadvantages:

- complexity of installation - you need to use expensive lifting equipment;

- fragility of products;

- no thread, so that the elements are fixed butt;

- difficulty in maintenance: cleaning products is complicated due to the high porosity, in addition, work associated with cleaning,can not be carried out without complete drainage of the well.

An important point is that asbestos cement cannot be used for artesian type of wells in limestone soil.

Plastic pipes are a great alternative for such an occasion. They are very popular for wells in recent times. They are made of polypropylene and PVC. The advantages of low pressure polyethylene include the following characteristics:

- such a device makes it possible to achieve exceptional tightness at connection points;

- for drilling, HDPE pipes are most affordable;

- in comparison with steel options, plastic is not subjected to corrosion processes at all.

- lightweight plastic casing;

- such a pipe can be operated for a long time and successfully under the influence of an aggressive environment;

- plastic casing is easiest to install yourself.

The most significant disadvantages are low mechanical strength and inability to dynamic loads. The important point is that plastic pipes should not be chosen for deep wells. The conditions of operation of wells with PVC pipes should be gentle.

If there is a question of choosing a pipe for a household autonomous water supply system, then plastic products are the best example of price / quality ratio.

Dimensions

The casing is designed to improve the quality of operation of the well. If you make an attempt to save on the acquisition of pipes, then not only the well itself, but also the equipment in it will quickly come into disrepair. Many believe that to improve the quality of the well it is better to choose a casing of larger diameter.

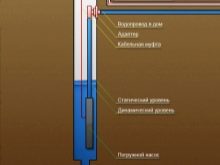

However, the larger the size of the casing, the higher the flow rate of the water source. To choose the right diameter of the casing must be aware of the consumption of resources. Standard water consumption per hour is 0.7 cubic meters. It is believed that this volume is sufficient for domestic and household needs. Another important parameter for determining the diameter of the pipe - the performance of the pump.

For example, the maximum consumption is 4 cubes per unit of time. For this value, equipment with a diameter of up to 8 cm is recommended. A possible distance of the pump to the walls of the casing, for example, 5 mm, is added to this parameter. Next, you can determine the internal diameter of the pipe: D (internal) = D pump + 5 mm; D (vnutr) - D internal casing; D (pump) - the diameter of the pumping equipment.

For example, if the pump size is 90 mm, then the value of the internal parameter will be: 90 + 5 = 95. With a pipe thickness of 5 mm, the calculated value of the pipe will be: 95 + 5 x 2 = 105 mm. Standard dimensions of casing elements: 89, 108, 114, 125 mm, 133 mm. For the given example it is enough to choose a pipe with a diameter of 108 mm.

The given example is simplified, Experts recommend to take into account the depth of laying casing elements. It will be necessary to lower the casing until the well reaches the aquifer. When this horizon appears, drilling stops and the upper end of the casing is fixed. The pipes are manufactured in lengths from 9.5 to 13 m with a normal and elongated thread. In the differences between species? Which option is most suitable for water wells?

Kinds

All types of casing pipes are structured in a special table of standard requirements. The thickness of the walls, as well as the diameter, must comply with the established regulatory indicators.

For products for wells, the usual accuracy is 0.7 mm per 1 meter of bore. The diameter of the pipe size can vary from 33.5 to 89 mm. According to the table, this figure is equivalent for pipes 108–146 mm.

PVC pipes for wells are usually blue with a hole diameter of 90–225 mm. For shallow or medium wells, products with a wall thickness of up to 5 mm are suitable. The walls of products for deep wells should be enlarged - from 5 to 13 mm.

The choice of casing can be associated with the method of interconnecting the parts into a single column. Connection methods are as follows:

- welding connection;

- bell fitting;

- threaded connection.

Welding is considered a hard joining of steel segments. In the arrangement of water wells, this method is rarely used. Weak characteristics of the method:

- The complexity and the need for a skilled worker.

- The need for special hold systems.

- Devices for holding must provide the necessary clearance.

- The appearance of corrosion in the joint.

- The possibility of inaccurate vertical. Welded metal pipe is more difficult to lower into the well.

Movable element connection is possible for both PVC and steel structures. The connection occurs by inserting the upper part into the lower part, which must be fitted with a socket. This option is possible for shallow wells.Because of the possible displacement of the segments and the violation of integrity, the variant is also used infrequently.

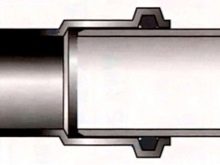

Threaded cages are the most hermetic assembly method. The method, by the way, allows you to install a combined column, which will include both steel segments and PVC parts.

The connection of elements with external thread is carried out by means of a coupling. If the casing thread is present on both the outside and the inside, then the segments can be screwed into each other.

Metal or polymer parts come with internal threads. To connect these elements need nipples. At the same time, if in the first variant of the joint, an increase in the diameter of the penetration is possible, in the second variant it is possible to increase the diameter of the hole; in the latter type of joint, the drilling diameter does not increase.

Installation

The well is being drilled into the ground of the drill, the diameter of which should be smaller than the diameter of the casing. The tool must be pulled out of the ground to remove contaminants. When the depth of the future well reaches two meters, it is possible to lower the casing element.

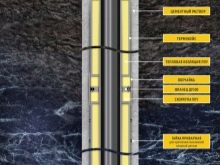

Further drilling with your own hands is carried out with casing until the appearance of the aquifer, if necessary, the pipe can be increased in one of the ways described above. Classic casing consists of the following parts:

- The initial filter for cleaning, which is usually a stainless mesh or wire.

- Bottom filter, which is made of gravel. It serves to protect the waters from pollution that can get under.

- Sealed tip, which serves as protection from external factors. Attaching a sealed tip will provide negative pressure, which will increase the water flow. For these purposes, cementing is sometimes used.

Using water from a newly drilled well is not recommended. Pump out fluid to make expansion as low as possible. With a more impressive amount of well at the bottom you will receive more water. With proper casing, wells can be saved on installation and replacement of technological elements due to their long-term operation.

Tips

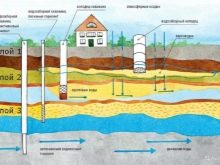

When choosing the best casing for the well, follow the classic combination of price and quality.These parameters should be determined by the durability of the structure. The optimal combination can be obtained only if you select the type of well correctly. There may be two options: artesian or up to the first layer.

There are much more design algorithms. It is better to make deep wells with metal and internal and external thread parts. Wells less than 55 cm deep can be cased with plastic elements with the same thread.

To determine the diameter of the pipe, consider the following indicators:

- dimensions of the submersible pump, planned for use;

- Wall thickness;

- the required minimum clearance between the casing and the pump;

- in the case of pipes with internal thread, the thickness of the nipples must be taken into account.

Fastening one-column casing in the ground occurs due to natural friction. Therefore, the caliber of the pipe must be necessarily larger than the diameter of the penetration.

The two-column element is attached by clamps, which play the role of centering. In this case, the annular space is necessarily filled with gravel or rubble along its entire height.

When arranging one-column casing, it should be borne in mind that it is not possible to pull it back.With a two-column scheme, the casing is pulled out with a jack with a massive strap. Silted casing can be cleaned, and the works are easily done by hand with the pump pulled out.

In the well is lowered tip with connected fire hoses. Inside the water is sent under high pressure. The level of water standing in the well can be any.

To learn how to make a well using the 125th pipe, see the video below.