Valve Features: Classification and Purpose

For modern pipelines, different types of shut-off devices are used. In order to choose the right fixture for a particular pipeline, you need to know exactly what this mechanism was made for and how to distinguish it according to the existing features.

Device and principle of operation

Locking devices produce:

- For pipelines that supply gas or water to buildings while still draining sewage from them. This is the most common area of their operation.

- For pipes through which harmful substances pass. Devices for chemical industry and oil and gas areas have excellent tightness and resistance to corrosion.

- For domestic water supply networks, for heat supply pipes and sewage systems.Devices that are mounted on private networks have oversized parameters and are easy to manage.

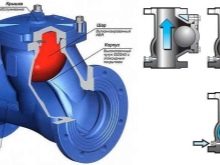

Shut-off valves (valves) have a structure of a robust housing with 2 ends for fastening and a seat that is closed with a special gate.

Plug valve, it is also called conical, it is one of the oldest types of water taps. Available in order to completely block or adjust the power of the flow of water. These cranes are available with a conical valve and with a cylindrical. These products can reach 34 inches and most often they can be seen in the highways having a working pressure of up to 70 MPa.

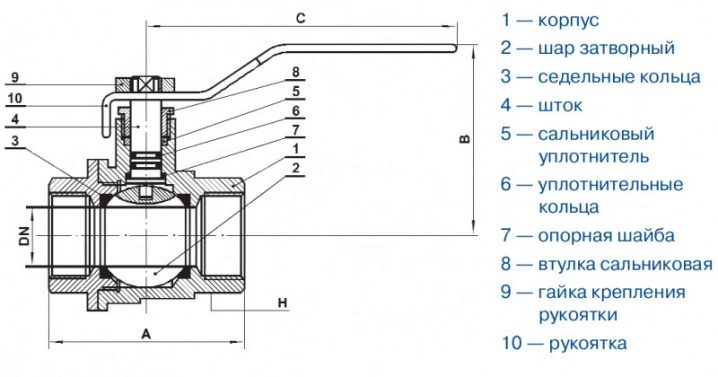

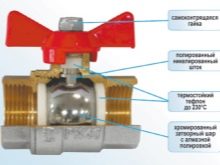

Ball valve characterized by the presence of a spherical plunger. Today, the use of ball products has been significantly expanded. The obvious advantages of this device include an affordable price, as well as the possibility of closing and opening with just a quarter turn of the handle. The ball valve ensures trouble-free movement of the flow, provided it is fully open with the lowest pressure drop. Simplicity during disassembly and maintenance, the ability to wipe the plunger and quickly remove dirt to ensure high-quality closure - this can also be considered a significant advantage of the ball valve.

Flange valve It has a structure of one or two disks, usually without an expansion mechanism. A number of flanged devices are manufactured using a soft seat, which allows you to compensate for various defects and guarantee the most dense disc fit. More often, these devices can be found in highways, where a low level of pressure is provided, where there is no need for tight closing. They are operated in the environment of gases, they can be used in the field of liquids. Flange products are usually from 2 inches in size and can easily withstand pressures up to 3 MPa.

Valve valve. The most important part of the device can be considered a saddle with a special gate that moves mechanically with the help of a spindle. The plumbing product has a thread in its housing and on the stem, and this thread can slow down the movement of the carrier. As a result, the valve disc should fit as tightly as possible to the seat, blocking the flow of the carrier when the valve closes.

The valve can be opened by simply turning the handle. The spindle then shifts, freeing the way for the carrier. If you move against the clock hand, the valve closes quickly.The mechanism is connected to the pipe through special nozzles. With each other, they are distinguished by the presence of an arrow, which should indicate the course of the flow.

Types and Specifications

The classification of valves for water is done according to several criteria, the main of which can be considered the type of construction.

On this basis, such devices are divided into:

- straight-through products;

- through valves;

- mixing devices;

- corner designs.

The use of mixing models is the mixing of different liquids, for example, two streams of water that have different temperatures. Modern enterprises produce special types of valves, for example, tubeless, which are installed in unusual situations. In their role can act as an excessively high temperature, and not quite typical environment.

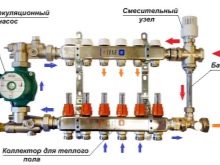

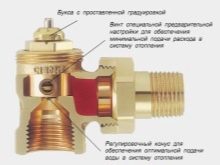

In the heating can also be found balancing mechanisms. This is a common device, with its help you can adjust the flow of coolant. In addition to the device in the case of a product there are 2 unions. They are needed in order to measure the pressure level before and after the adjustment mechanism and to connect the capillary tube and facilitate its interaction with other elements during control.

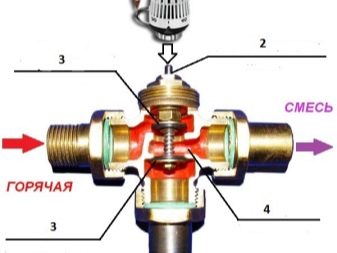

Among the valves of stop type for heating systems there is 1 element, which can be seen quite rarely. Its shape resembles a tee, but at the same time it performs other functions. This is a three-way valve with a special principle of operation. This product is mounted in those places of the pipe where there is a need to break the circulation flow into 2 circuits, one with a constant hydraulic mode, the other with variable ones.

The action of a special electromagnetic product is concluded on opening or closing the opening of the passage in the valve pair, using a targeted effect on the plunger of the magnetic field from an electromagnetic-type coil.

If you take into account the features of the functions performed, the valves also come in:

- locking mechanisms;

- shut-off regulatory products;

- details of special purpose.

The closure part will differ in structure.

The ball valve has the structure of a through sphere located in the body. When the axes of the hole and the body itself are combined, the movement of the carrier begins. Perpendicular rotation will completely close its flow. Here, the valve plays the role of only the element for locking, and it is not intended to regulate the flow.

The valve has a lock that is connected with a threaded rod, and that, in turn, is screwed into a special landing nut. The product is used to adjust the flow or to completely shut off the flow through the pipes.

The needle-shaped piston has a tapered appearance; it can be used to regulate the flow of fluid under fairly high pressure.

High pressure devices can be actively used to regulate and lock media, most often they are found on industrial boilers. The diameter of the water pipes where these products are mounted usually reaches 100–300 mm, the temperature can be 450 degrees, and the pressure level up to 2.5 kg per 1 cm2.

The classification of the devices of the shut-off and regulating type can also be offered according to the following criteria:

- on the hull structure;

- by types of the locking part of the product;

- according to the scheme of installation of the structure in the system you need;

- by type of connection.

The shape of its body products are divided into angular equipment and direct-flow type design. Corner parts allow you to adjust the flow of the carrier by the locking element turned towards it (the hole in this case will bend at a certain angle when moving from the fitting to the saddle of the device).In the equipment of the direct-flow type, the flow regulation is performed by the transverse displacement of the mechanism (the product saddle will be within the boundaries of the bore hole).

Shut-off and regulating mechanisms for plumbing most often available only in the corner versions. A straight-through type of housing is used as the basis for the valves of constipation.

Depending on the method of installation, the structures are divided into the following types.

- Coupling. Go only under the threaded type of installation. For this reason, the ends of the valve are threaded either outside or inside. Mechanisms of this type are made of brass and steel. Brass found only in pipelines for domestic purposes. These devices are mounted in highways, which have a small level of pressure of the carrier - up to 1.6 MPa. You can find another design of this kind of reinforcement. You can easily purchase a brass clutch mechanism for installation on threaded fittings.

- Flanged. Have the steel case or are made of cast iron. Installation is carried out on a specific principle. The ends of the housing of this device are completed with flanges. This equipment is very durable.For this reason, the main area of operation of this part can be considered communications with an average pressure level of 10 MPa. This feature helps to use these devices in all sorts of pipelines.

- Passable. These mechanisms are installed on the site of water supply. The design of the part can be of 2 types: bellows (the most hermetic) and stuffing box.

Of the minuses of the device, professionals highlight:

- severe hydraulic resistance;

- very substantial weight;

- the complex structure that occurs due to the fact that to simplify the actions of the passing mechanism is often supplemented by an electric drive;

- large parameters;

- the presence of a zone of stagnation - there may accumulate particles of rust, and this is the way to corrosion.

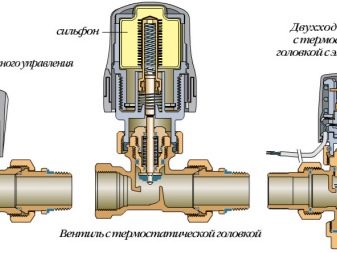

Functional purpose

The valves can be designed for water and can be gas, built into the heating system of any home. Thermostatic valves are designed to integrate heating devices into the overall system. Quite often in houses there are temperature-controlled products for the air conditioner and for the heated towel rail, and on the street people use thermostatic devices on the batteries,that are placed in the supply pipe of each radiator in order to best adjust the coolant flow depending on the temperature in the room itself.

By the form of the locking part of the product are divided into ball, with valves and membrane-type designs.

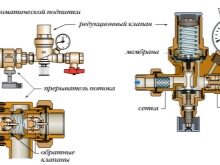

The first two types were considered a little higher. The diaphragm valve is mounted in the forward flow housing. The main element of constipation is a flexible tube, pressed by a guillotine type gate. These devices are used as regulators in pipes for sewage or in systems for transferring viscous or even loose substances (sand or cement, for example). The performance of the membrane product as a locking part is very doubtful. The fact is that the shutter in the form of a guillotine cannot guarantee the complete tightness of the product.

The valve for tapping under pressure is a special pipeline part that performs a number of tasks. Firstly, it is a saddle tap, with its help the installation of branches of the additional pipe running from the main pipeline is carried out. Secondly, the product plays the role of valves of the locking type, which can open or close the transfer media.

Materials

The steel aggregate is more commonly found in pipe systems for adjusting the flow of steam, liquid or gas. Steel can withstand elevated temperatures and different levels of pressure, which in such systems can sometimes reach up to 425 degrees above zero and 6.3 MPa.

Brass valve is found in systems for transferring working media in liquid and vapor form. The sealing rings in these devices are most often paronitic, the stuffing box packing is made of asbestos. Nominal diameter can be selected in the parameters from 15 to 50 mm, the weight of the device - 0.25-1.58 kg. Chrome brass is very popular.

Cast iron valve can be found on pipes having a diameter of from 0.5 to 3 m. The housing of the device is made of a certain grade of cast iron. The mechanism of constipation is a complex in appearance design, which consists of such components as the omentum, valve and flywheel. Most of the parts of this design are made of steel.

An alloy of brass and bronze is resistant to corrosion. With the release of bronze parts with thread, they do not stick one to the other and after many years can be easily unscrewed. They are made by casting, then processed on the machines.It should not be forgotten that both brass and bronze are completely safe in terms of ecology.

Plastic valves and ball products for water pipes are polypropylene or polyethylene. These units are not afraid of chemical and electrochemical corrosion, for this reason they are absolutely indispensable in those pipes through which aggressive substances pass.

What is different from the valve?

Gates and latches are 2 mechanisms that are most often found on industrial pipes. Without them, it is impossible to imagine the work of any possible supply system and no matter what size it is. The main purpose of this type of device is extremely uncomplicated - to give the opportunity to control the movement and a certain state of the fluid that is transported inside the pipeline.

Many ordinary people often confuse or do not initially know what the valves look like and why they need valves. Many believe that there is no difference between this equipment at all, and some ordinary people, on the contrary, believe that each of these devices has uncharacteristic properties.

The valve is a locking mechanism for adjustment.This is a rather large element, with a slightly thickened body and with an overall adjustment ring, which is called its valve. It is necessary in order to 100% shut off or adjust the flow of the used fluid inside the pipe.

This is the main difference between a modern valve and a conventional valve. The detail of the valve, which is fixed, can be mounted in several positions without any problems.

If you turn the valve on a series of turns, the flow will be blocked only partially. The constipation element will artificially make the inside diameter of the passage smaller, which will limit the amount of transported media. The complete closure of the mechanism will block the entire system, approximately the same is done by the valve. But the main advantage of the valve is that it can be used to select the desired position for the locking element inside the device itself.

Quite often in industrial pipes there is a need not to completely block the flow of the carrier, but only to make it smaller to a specific value. This can be done by mounting the valves in the most suitable places for this.

List of obvious differences.

- The valve can easily adjust the flow force in any system, the valve can only be seen in two states: it can be open and closed.

- The latch quickly comes into disrepair. The valve serves more thanks to excellent characteristics.

- In the valves, the flow of the carrier will be blocked by a special valve, which is pressed against the seat in horizontal planes parallel to the flow of gas or water. For this purpose, a double bending of the carrier flow is carried out at an angle of 90 degrees. The valve will be blocked perpendicular to the flow of the carrier.

For how to repair and replace the screw valves, see the following video.