How to choose an aluminum pipe?

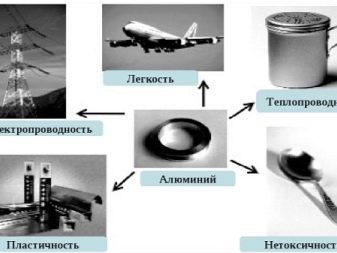

Aluminum is one of the most sought-after metals, widely used in both industrial and household applications. Due to its technical characteristics, it can be used for the production of products where factors such as strength and lightness are needed. Such products include aluminum pipes that are easily bent, welded and processed.

Special features

Aluminum pipes are characterized by high performance properties that allow these products to be used in completely different industries. They are able to serve several decades without deformation and destruction.They are not affected by temperature fluctuations and various external stimuli, so that products can be successfully operated in all weather and climatic conditions.

Advantages of aluminum pipes:

- high strength;

- relatively light weight;

- corrosion resistance;

- resistance to high and low temperatures;

- chemical resistance to most acid solutions and alkalis;

- high level of resistance to mechanical damage;

- smooth surface;

- low thermal conductivity;

- bactericidal properties;

- long service life (up to 100 years);

- practicality.

Quality aluminum pipes should not have the following defects:

- cracks;

- bundles

- shells;

- foci of corrosion and traces of friability;

- burrs and other rough edges;

- on products that have undergone heat treatment, there should be no signs of burnout.

According to GOST, on the surface, the presence in the minimum size of such defects as:

- scratches;

- Pressing and nicks;

- dents that do not affect the diameter change;

- spots;

- spiral and ring strips;

- traces of industrial grease.

Among the disadvantages are the high cost of products.The price of aluminum pipes is slightly higher than that of analog products made of steel or polymers. But at the same time their high operational properties fully justify such costs.

It is worth noting that round and rectangular pipes made of aluminum are easily subjected to mechanical stress, and the strength properties at the same time are fully preserved. Pipes are connected by welding or with metal fittings.

Often, aluminum pipes are used when laying water pipes - their smooth surface contributes to high throughput, which allows you to quickly pump water and other liquids. However, aluminum is not suitable for laying the drinking pipeline, since it emits harmful substances to human health.

Kinds

Aluminum pipes are of different types. There are several methods for their manufacture.

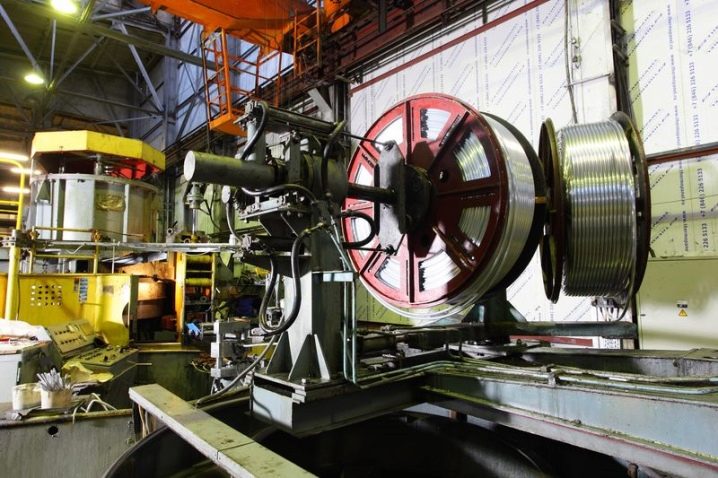

- Cold deformation. Using this method, make the profile and ordinary products. The blank for them is an aluminum circle, which is then pulled out, shaped and calibrated.

- Pressing. The blanks are made on the basis of special presses.

- Welding. Aluminum sheets are welded to the shape of pipes.In this case, the voltage that occurs on the workpiece, is removed by the method of "hot vacation".

It should be noted that the profile tubes are not subject to this classification, as their thickness in different places corresponds to different indicators.

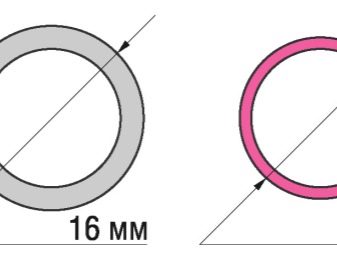

The diameter of the pipe and the thickness of the walls are classified into:

- thin-walled - thickness less than 5 mm;

- thick-walled - thickness over 5 mm.

By the way of processing aluminum pipes are divided into:

- hardened;

- naturally aged;

- annealed;

- hardened.

The length of the pipe are:

- dimensional;

- unmeasured;

- long and short measured length;

- pipes in coils.

Round tubes

These metal products are used in the sanitary field, in particular, for the construction of hot and cold water systems, as well as in the arrangement of the heating system. It is worth noting that aluminum has a weak ductility, therefore, for installing underfloor heating, where many pipe bends are provided, is impractical.

Round tubes are made of different wall thickness and are divided into:

- pressed;

- cold deformed;

- seamless;

- welded.

Depending on the type of aluminum alloy, there are several pipe sizes:

- aluminum brands AMC, AD0 and A1 make pipes with a diameter of 8-40 mm, wall thickness can vary from 1.5 to 2.5 mm;

- D16, D1, AMg2 aluminum grades make large diameter pipes from 10 to 130 mm with a wall thickness of 1-5 mm;

- AK6 aluminum is made of thick-walled products, the wall thickness of which reaches from 20 to 73 mm, such pipes are used mainly for the construction and installation of supporting and protective structures.

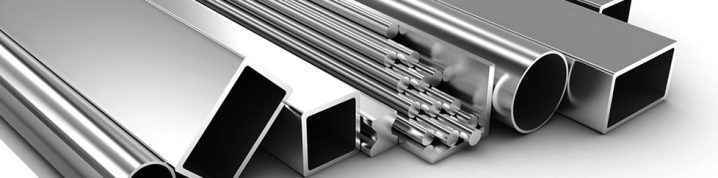

Profile pipes

This type of products is used only in construction. They are not suitable for arranging heating and water supply systems.

Profile types:

- oval;

- flat oval

- square;

- rectangular.

As you can see, the aluminum profile on sale can be found completely different shapes. One of the most popular types of profile is an L-shaped corner, without which it is impossible to do during construction and even repair. Corners are standard size 50x50x3 mm without cavities and notches (it is also called ravnopolochny) or they may have other sizes: 50x50x5, 60x40x2, 1000x40x4 mm and others. Depending on the size, the scope of the profile changes.

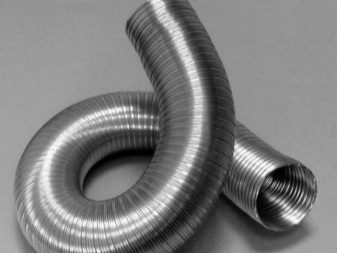

Corrugated pipes

Scope - arrangement of chimneys, ventilation systems, water supply, heating, as well as the creation of pipelines for gas transportation. Due to ribbing, the elasticity of products at a high level. Therefore, they are often used in places of laying with a lot of bends. For gas transfer only thick-walled pipes resistant to high pressure are used.

Corrugated products are produced with a diameter of 10 to 70 mm for the pipeline, for ventilation use large diameter pipes from 50 to 2500 mm. The tightness of the joints is provided by special sealing rings along the inner contour, which are mounted between the rows of the corrugations.

Aluminum finned tubes are not used for laying cables, as well as electrical insulation, as aluminum is a material that does not conduct current.

Aluminum reinforced pipes

Reinforced metal-plastic pipes are widely used in the areas of water supply and heating. Today they have become an absolute substitute for steel and copper pipes, as well as stainless steel products.

This tube is a product of three layers - two outer shells of polyethylene, an intermediate layer of aluminum foil. Reinforced structures are distinguished by minimal vapor permeability and increased pressure (up to 25 bar).

Duralumin tubes

Duralumin alloy D16T is widely used in the food industry, energy, construction, aircraft and automotive industry. It is in great demand in the oil, chemical, gas, pharmaceutical and food industries.

Dural pipes are a hollow profile, the size of the products varies. Technical and operational properties are largely determined by the method of their production, chemical composition, state of the material. Differ in ease, high rates of fatigue durability, static durability, plasticity, and also simplicity of processing.

Of the minuses, there is a low corrosion resistance. But this disadvantage is covered by anodic oxidation and plating. It is worth noting that the mechanical properties of duralumin pipes suffer from an excess of iron. Since it does not dissolve in aluminum, but is collected in some plates, the strength and ductility of the products is reduced. Therefore, during the acquisition of aluminum is worth paying attention to quality.According to GOST, iron in duralumin should not exceed 0.5-0.7%.

Duralumin pipes do not need additional processing. The size of the blanks after quenching is not reduced.

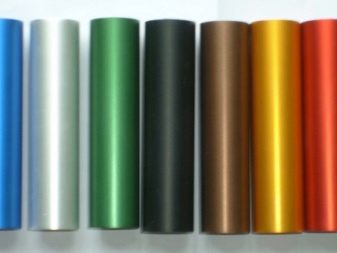

Anodized aluminum tubes

Today, these products are superior to copper and steel structures. They are widely used in areas where the weight of the structure is particularly important. From the technical characteristics can distinguish strength, flexibility, ductility. They are easily connected by welding and can be used as a profile pipe.

Anodized pipes are considered more resistant to corrosion, precipitation and temperature, which makes them popular in the manufacture of air conditioning and ventilation. And also they have high decorative properties, due to which they are widely used in interior and exterior design.

Technical aluminum

Aluminum AD1 is another popular alloy of this metal. It has high strength, but the presence of impurities in the composition reduces its plasticity. But the alloy withstands the effects of chemicals, surpassing all other metals in this indicator. Amenable to all types of welding, easy to process, but difficult to cut.Used to create various semi-finished products, as well as a plating material for other aluminum alloys that are less resistant to corrosion.

Aluminum grades

Foreign series include about 40 different alloys of aluminum with other metals. According to the national GOST, there are 9 grades of aluminum, each of which is distinguished by an individual characteristic, composition, properties. Compliance of Russian and foreign brands is given in the table.

Scope of application

Currently, aluminum is considered one of the most sought-after metals.

Due to its technological qualities, it is successfully applied in a wide variety of fields.

- Aircraft engineering, shipbuilding. Durable, lightweight aluminum pipes and other elements of this material meet all the standards necessary for these industries.

- Pipeline. The surface of aluminum pipes is characterized by high smoothness, which allows to transport various liquids without high resistance.

- Transportation of aggressive means. Aluminum is highly resistant to chemicals and various acids.This allows their use in air conditioning and ventilation systems.

- Professional equipment. Aluminum and its alloys are the main metals for the production of shop windows, cabinets, counters, advertising racks and much more.

- In everyday life, aluminum pipes are used in interior design. For example, to create windows, doors, railings, racks, stairs, fences, furniture, gym equipment and other household items.

Aluminum is perfectly combined with all sorts of building materials. In addition, it is extremely practical, functional and has an excellent appearance. That is why it fits well in any style.

It is worth noting that at the present time aluminum is slowly but surely displacing other metals and alloys. This is especially true of the production of air conditioners. In the automotive industry, aluminum tubes for refrigerant have been used for a long time. But in commercial air conditioners aluminum is only being introduced into production.

Although more recently, industry leaders such as Haier and Midea Air-Conditioning have come to the use of aluminum as the main material, launching a line of equipment with aluminum heat exchangers.Duralumin pipes have found application in the manufacturing sector, mechanical engineering, chemical, shipbuilding, fuel, aviation industry and construction.

Manufacturers

At the moment in Russia there are several undisputed leaders of aluminum pipe rolling. Among the multitude of manufacturers stands out one corporation - Alcoawhich combines two large plants "Samara Metallurgical Plant" and "Belokalitvinsky Metallurgical Production Association". Speaking in numbers, 50% of the market is represented by the goods of these brands. Therefore, the rest of the manufacturers have to build on the prices that this plant sets.

The second place in terms of rolled products is "Kamensk-Uralsky metallurgical plant"which is engaged in release not only pipes, but also sheets of the main brands.

Products of the plant are very popular with consumers. "Russian aluminum pipes" which is engaged in the production of pipes for air conditioning. This manufacturer uses high quality aluminum to transport refrigerant between the units.The use of aluminum has reduced costs and installation time.

Tips

Regardless of the scope of application of aluminum pipes, in the process of installation it is impossible to do without connecting elements, cutting and joining products with other structural elements. On sale, all pipes are smooth, strictly rectilinear form. If the shape of the structure implies the use of direct products, then the pipes are only cut and adjusted to the size.

But if you need to give a certain shape, the products are subject to bending. Aluminum is a rather soft metal, so most consumers say that bending the pipe is easy. Future pipe blanks are bent on special machines, where you can adjust the profiles of different shapes. The dimensions of future pipes are influenced by the thickness, shape and length of the profile.

The procedure for connecting pipes can occur in several ways:

- bolted connection;

- welded joint;

- flanging method.

Most often resort to welding of pipes. This method is considered the most reliable and at the same time simple in execution. Welding is of two kinds: under pressure and fusion welding.Skilled craftsmen prefer to use the melting method when working with aluminum pipes, since there is no need for special equipment, unlike the second method. It is best to use electron-beam welding or arc welding using inert gas.

When processing aluminum profiles, it is important to observe safety precautions after taking care of protective clothing.

For information on how to connect two aluminum ventilation corrugated tubes to each other when assembling an air manifold, see the following video.