Water pipe diameters and sizing tips

Water pipes are the main element of the water supply system for residential premises and industrial buildings. When choosing quality pipes, it is necessary to take into account the materials from which they are made, size, wear resistance and other characteristics. On the peculiarities of the size and nuances of the choice of water pipes will tell our article.

Special features

By type of material manufactured All pipes for hot and cold water are divided into three groups:

- metal;

- plastic;

- metal plastic.

The former are made from metals such as copper, cast iron and steel. The second - from various polymers. Still others combine the qualities of metal and plastic products.In recent years, this versatility has become decisive in the choice of material for water supply, drainage and heating systems.

The most important parameter of any pipes is the diameter, which must necessarily meet the requirements of GOST. However, different manufacturers may have small deviations in the size of products, so it is desirable to purchase pipes and components for installation from one manufacturer. In other cases, only a master with great experience will be able to correct the errors and solidly mount the water supply system.

Standard parameters

Next, we consider the size of pipes made from different materials. This table shows the parameters of pipelines of steel according to GOST 854362989.

The dimensions shown are standard for galvanized products and pipes made of stainless steel.

Diameter of external pipes, mm | Wall thickness mm | Weight of one meter, kg | ||||

Lungs | Common | Amplified | Lungs | Common | Amplified | |

10.2 | 1.8 | 2.0 | 2.5 | 0.37 | 0.40 | 0.47 |

13.5 | 2.0 | 2.2 | 2.8 | 0.57 | 0.61 | 0.74 |

17.0 | 2.0 | 2.2 | 2.8 | 0.74 | 0.80 | 0.98 |

21.3 | 2.3 | - | - | 1.10 | - | - |

21.3 | 2.5 | 2.8 | 3.2 | 1.16 | 1.38 | 1.43 |

26.8 | 2.3 | - | - | 1.4 | - | - |

26.8 | 2.5 | 2.8 | 3.2 | 1.50 | 1.66 | 1.86 |

33.5 | 2.8 | 3.2 | 4.0 | 2.1 | 2.39 | 2.91 |

42.3 | 2.8 | 3.2 | 4.0 | 2.73 | 3.09 | 3.78 |

48.0 | 3.0 | 3.5 | 4.0 | 3.33 | 3.84 | 4.34 |

60.0 | 3.0 | 3.5 | 4.5 | 4.2 | 4.88 | 6.16 |

75.5 | 3.2 | 4.0 | 4.5 | 5.71 | 7.05 | 7.88 |

88.5 | 3.5 | 4.0 | 4.5 | 7.34 | 8.34 | 9.34 |

101.3 | 3.5 | 4.0 | 4.5 | 8.44 | 9.60 | 10.74 |

114.0 | 4.0 | 4.5 | 5.0 | 10.85 | 12.15 | 13.44 |

140.0 | 4.0 | 4.5 | 5.0 | 13.4 | 15.04 | 18.14 |

165.0 | 4.0 | 4.5 | 5.0 | 15.88 | 17.81 | 21.63 |

In the manufacture of metal pipes, the main reference point is considered the outer diameter. For industry, large-sized pipes (from 530 to 1420 millimeters) are most often produced, medium pipes (from 114 to 530 millimeters) are made for municipal services, and small pipes (from 10 to 108 millimeters) are made for apartment buildings and private houses.

Metal products are considered to be the least practical for installation of water pipes due to unavoidable corrosion and the need for additional protection from it with a layer of zinc (galvanized pipes). They are also very heavy and require the use of special equipment during installation: trucks, cranes, etc. But despite this, they continue to be used in industrial technological structures.

Copper pipes are also used for internal plumbing. Despite the high price, these products are very practical and durable. They are resistant to corrosion. On their walls there is no raid and other sediments. They are not afraid of possible narrowing in the design. They are able to withstand large temperature differences - from minus 110 to plus 250 ° C. Their service life ranges from 30 to 60 years and even more.

The size of copper water pipes (and others too) necessarily depends on the number of units of the connected plumbing. If there are many connections, then the pipes should be larger. For hot and cold water suitable pipes of a single diameter, but in the second case, the walls should be thicker. The table shows the parameters of the copper pipeline in millimeters, but most often the dimensions are given in inches (for example,the 15 mm pipe is 1/2 inch, and 20 mm is 3/4 inch).

Outer tube diameter, mm | Weight 1 m, kg | Wall thickness mm | ||||

ordinary | easy | reinforced | ordinary | easy | reinforced | |

165 | 17.81 | 15.88 | 21.63 | 4.5 | 4 | 5.5 |

140 | 15.04 | 13.4 | 18.24 | 4.5 | 4 | 5.5 |

114 | 12.15 | 10.8 | 13.44 | 4.5 | 4 | 5 |

101.3 | 9.6 | 8.44 | 10.74 | 4 | 3.5 | 4.5 |

88.5 | 8.34 | 7.34 | 9.3 | 4 | 3.5 | 4.5 |

75.5 | 7.05 | 5.71 | 7.88 | 4 | 3.5 | 4.5 |

60 | 4.88 | 4.2 | 6.16 | 3.5 | 3 | 4.5 |

48 | 3.84 | 3.33 | 4.34 | 3.5 | 3 | 4 |

42.3 | 3.09 | 2.73 | 3.78 | 3 | 2.8 | 4 |

33.5 | 2.39 | 2.1 | 2.91 | 3 | 2.8 | 4 |

26.8 | 1.66 | 1.5 | 1.85 | 2.8 | 2.5 | 3 |

21.3 | 1.28 | 1.16 | 1.43 | 2.8 | 2.5 | 3 |

17 | 0.8 | 0.74 | 0.98 | 2 | 2 | 2.8 |

13.5 | 0.61 | 0.57 | 0.74 | 2 | 2 | 2.8 |

10.3 | 0.4 | 0.37 | 0.47 | 2 | 1.8 | 2.5 |

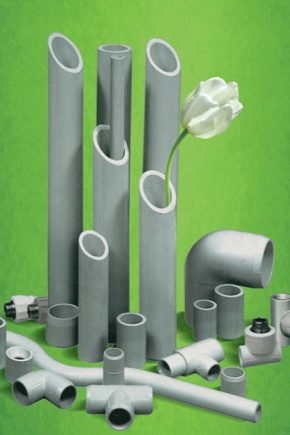

The most modern pipes are made of polyethylene (PE), polypropylene (PP) and metal-plastic (MP). The sizes of these products are determined by GOST. Their diameter ranges from 20 mm to 1200 mm.

The most commonly used pipes are 63 mm, 80 mm and 100 mm in diameter.

- A polyethylene tap product with a diameter of 63 mm is used very rarely, since it does not have a large margin of safety and can crack, withstanding internal pressure for a long time.

- The 80-mm pipe is resistant to constant high pressure, therefore it can be used for water from 0 to 40 ° C, as it is produced from low-pressure polyethylene.

- Polyethylene tap products with a diameter of 100 millimeters are used more often, as they are made by extrusion and are suitable for use at temperatures from 0 to 40 ° C.

Next, we consider plastic pipes labeled PN10 and PN16. Water pipes (PN10) are used only for cold water with a temperature up to 20 ° С. Pipes withstand a pressure of 10 atmospheres. The calculation is given for a pipe length of 4 m.

Size, mm | Outer diameter, mm | Wall thickness mm | Water consumption, l / m |

20x1.9 | 20 | 1.9 | 0.106 |

25x2.3 | 25 | 2.3 | 0.317 |

32x3.0 | 32 | 3.0 | 0.531 |

40x3.7 | 40 | 3.7 | 0.834 |

50x4.6 | 50 | 4.6 | 1.307 |

63x5.8 | 63 | 5.8 | 2.071 |

75x6.9 | 75 | 6.9 | 2.941 |

90x8.2 | 90 | 8.3 | 4.154 |

110x10.0 | 110 | 10.0 | 6.360 |

Plastic (propylene) water pipes (PN16) are intended only for hot water with a temperature of up to 60 ° C. Pipes withstand a pressure of 10 atmospheres. The calculation is given for a pipe length of 4 m.

Size, mm | Outer diameter, mm | Wall thickness mm | Water consumption, l / m |

20x2.8 | 20 | 2.8 | 0.206 |

25x3.5 | 25 | 3.5 | 0.317 |

32x4.5 | 32 | 4.4 | 0.531 |

40x5.6 | 40 | 5.5 | 0.834 |

50x6.9 | 50 | 6.9 | 1.307 |

63x8.7 | 63 | 8.6 | 2.071 |

75x10.24 | 75 | 10.3 | 2.941 |

90x 2.5 | 90 | 12.3 | 4.154 |

110x15.2 | 110 | 15.1 | 6.360 |

Nowadays, fire-resistant plastic pipelines have appeared. As the name implies, they are used in extinguishing fires. In such a system, combined polypropylene pipes are used, which are made of non-combustible materials, having high-strength compounds and not subject to corrosion. These properties guarantee fire tubes a very long life.

How to choose?

The correct diameter of the water pipes ensures high quality and uninterrupted operation of the system. For example, pipes of 25 mm per minute can miss about 30 liters of water, while a pipe of 32 mm will allow 50 liters of water to pass during the same time. It should not be forgotten that the mixers pass only five liters per minute.You also need to take into account the speed of water movement in the pipeline (approximately 20 meters per second) and the length of the entire water supply system. So it will be easier to choose the diameter of pipes: up to 10 meters - 20 mm; up to 30 meters - 25 mm; more than 30 meters - 32 mm.

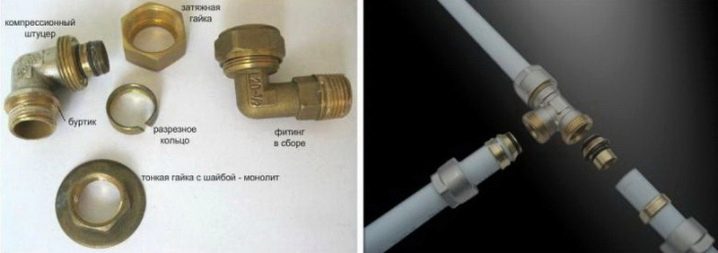

When designing a water supply system with a large number of connections, turns and points of analysis, you should choose pipes with a large diameter. And when joining pipes of mixed type, for the best build quality, it is necessary to use fittings of the same diameter. When working with aluminum and copper pipes, more careful selection of parts is necessary, because they are necessarily manufactured according to the metric standard and are used exclusively for installation in the apartment.

In apartment buildings and private houses, various plastic (polyethylene, propylene) pipes are now most often used for drainage and water supply. They are easily and quickly mounted, as they are sold in a bay (roll) of a hundred or two hundred meters. During installation, the pipes are gradually unwound from the bay to the required distance in one piece without any rations or connections. Already this one is profitable.

You do not need to solder four-meter pipe sections, but you can simply lay a trunk of the desired length.Installation from rolls is easy to implement - you do not need to be a great specialist, there will be enough superficial knowledge of the connection to collect at least part of the water supply yourself.

Beware of fakes. If the pipe is black, it does not mean at all that it is worse than blue or blue. The product of any color can be made from primary and secondary raw materials. Look at the pressure classification. The common pressure of pipes is 6 or 10 atm. A 6 atm product made from recycled materials (both black and blue) will be worse quality than black made from recycled materials, but 10 atm, or blue of the same value, made from primary.

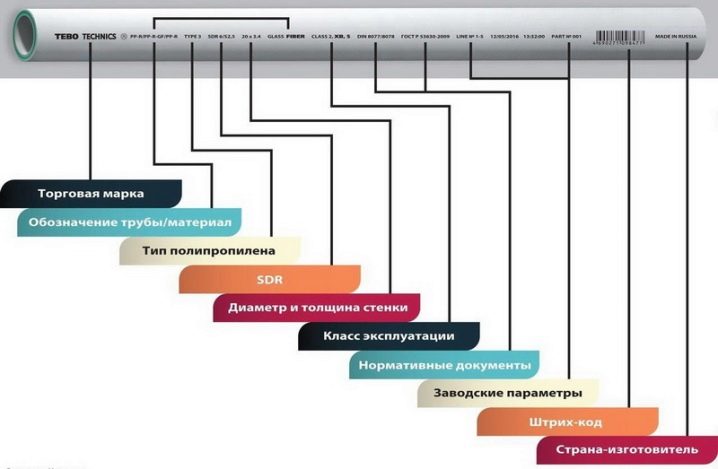

Marking is located on the pipe itself. It looks, for example, as follows: pipe PE 80 32 (size) 2.4 (wall thickness) drinking 10 atm 737 m (length). If nothing is written on the pipe, then you should not buy it. There are two more ways to check the quality of plastic pipes - compress the edge and inspect the inside. If the edge of the product holds its shape during compression, it is of high quality If it is flattened under pressure, this indicates a poor-quality product. If the inside of the pipe is rough, not smooth, then it is also of poor quality.

Metal-plastic pipes are often not used, not because of the quality of the pipe itself, but because of the fittings to it, since many fakes have recently begun to appear. Therefore, you need to be very careful when choosing the elements of water supply.

When installing the system, it is recommended to strictly follow certain instructions. It is necessary to prepare the required number of pipes, adapters, fasteners (clips). And most importantly, it is necessary to comply with all sizes of pipes and their connections. After all, any, even the smallest mistake, can break the tightness of the finished system. Such water supply will not be reliable, durable and will surely give a leak.

Tips

- Choosing pipes, do not forget about their thickness. To use cold water, thinner pipes may be suitable; for hot water, thicker ones.

- When buying polypropylene and polyethylene products it is necessary to pay attention to the availability of a certificate and detailed information on the standard of conformity. It is important to check (find out) all marking values of materials, dimensions and thickness of walls, pressure.

- When buying metal-plastic, be sure to check the type of plastic and the size (outer), the batch number and the date of manufacture.Be sure to check the nominal pressure values.

- Before starting work on the installation of water supply, you need to make a plan, identify areas for which you can mount the individual parts of structures, to subsequently connect them into a common chain.

How to understand the size of water pipes, see the following video.