Pipe Runs: Design Features and Installation Tips

Usually the pipes are attached to each other, as well as joined to the plumbing and gas structures with the help of couplings, inside which the thread is made. But in the case when these sections are located too close to each other, the clutch will not work, since the direction of the thread will coincide. In other words, a situation will arise when the non-rotary parts try to connect. It may also happen that welding will be impossible. Therefore, it always makes sense to use rolls - special intermediate sections for the pipeline, providing high-quality connection and protecting from leaks.

Specifications

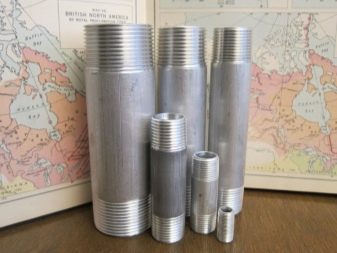

Sgon looks like a piece of pipe, on both sides of which a thread is made. The segment must be straight or angular.From the short side, the thread consists of 5 turns, and from the long side - from 20 turns and more, up to 30. The short end connects to the branch pipe of the equipment, for example, a gas boiler or a battery, and the long end connects to another pipe. The long thread also "goes" clutch of a selected size with a lock nut.

On the other pipe is placed a sleeve with a seal for sealing, which is pressed against the lock nut. The latter can be linen tow, sanitary thread or other materials.

Carriages are made of metal, often “reinforced” by a zinc coating. If you want a decent appearance of pipes, it is possible to purchase items with nickel-plated. Often on the marking of the sgon is indicated two numbers, for example, 75/76. It says that the outer diameter of the product is 76 millimeters, and the inner diameter is 75 millimeters.

Parameters (the length of thread turns, its diameter and the size of the slip in inches) must be observed according to GOST and correspond to the dimensions of the installed pipeline, for example, 25 millimeters (1 inch). The maximum sgon diameter is 50 millimeters, the minimum is 15 millimeters.If the diameter of the pipeline itself is larger, then the solution of the problem is carried out through the use of flanges.

The maximum length of the fitting is 160 millimeters (for a diameter of 50 mm), and the minimum is 110 millimeters (for a diameter of 15 mm). These indicators again can be found in GOST. However, in practice, reality often does not meet the standards, so it’s better to measure everything yourself and buy parts of the required length.

There is a classification of sgonov depending on the scope of their application: short, long and compensating. The latter are used for plumbing, batteries and other devices in order to minimize deviations within 5 centimeters, detected during installation. The length of short sgony is from 10 to 15 centimeters, and long - about 30 centimeters. The length of the compensating angle varies from 13 to 17 centimeters.

The short thread at the short view is from 5 to 9 centimeters, and the short - from 9 to 17 millimeters. In general, the dimensions of the short side are the same for all types of shafts. The long side of the long sleeves also varies from 5 to 9 centimeters. The long side of compensating sgons is from 7.5 to 10 centimeters.

The main advantages of operating sgony include:

- simple installation without welding machine;

- no need to invite a specialist;

- the appearance of a special unit that simplifies disassembly in case of need for repair, cleaning or replacement.

By the way, dismantling takes place in the following sequence: first the nut, then the coupling, then the assembly itself. It is disassembled using a lever key.

Among the minuses emit the likelihood of a leak due to the lack of tightness.

Purpose

The method of connecting the pipeline elements depends on several factors, for example, the material used to make the pipes, the type of substance being transported, and the conditions of the working medium. The main purpose of pipe runs is to connect them to plumbing or gas appliances. Welding is not suitable here, because the connection must be detachable: if necessary, some element may have to be dismantled. For example, sgony advised to apply in the heating network after the valve on the riser.

In the event of a breakdown, the presence of a sgon will make it easy to reach the valve element to repair or replace it. Sgona will be useful for cast-iron old radiators, their presence will contribute to the cleaning of the pipeline.This element is used to connect various heating equipment: tanks and gas boilers, as well as mixers. In the kitchen, sgon is useful when connecting the stove. Finally, it can be used to create an additional branch pipe.

Connection features and installation

Drives are capable of functioning in systems where the temperature reaches 175 degrees and the pressure does not exceed 16 atmospheres. The fitting is sold together with the coupling and lock nut of standard sizes.

Installing sgony to be a specific algorithm. It can be explained by the example of a part installed after the valve. The length of the fitting is determined so that the part is somewhere around 5 millimeters shorter than the clearance between the pipes. This necessarily takes into account the future deepening of one side in the pipe attachable equipment.

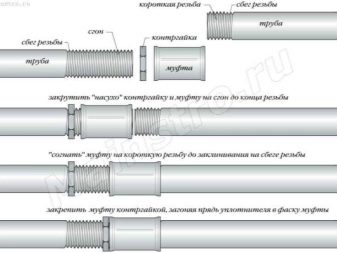

On the long side of the sgon (that is, on the one where there are at least 20 turns) a steel locknut and coupling are screwed in the kit. The short side is wrapped along the thread with flax fiber with mandatory impregnation with any paint, varnish or sealing thread.

Next, this short side is covered with a special paste and screwed into the thread of the nozzle, in this case the valve. At first, everything is done manually, and then tightened with a gas key. At this time, be sure to hold the valve itself, for example, with another key, so that it does not crank. Otherwise, a leak is possible.

The clutch on the long side is “driven” down and wound onto the pipe with a gas wrench. Behind it comes down and lock nut, until between it and the coupling will not be 3-4 turns of thread. At the other end of the coupling, the flax fiber is wound, everything is coated with paste, and the lock nut is tightened.

During operation there may be several typical problems that are quite easily solved.

- If a locknut is flowing, this indicates that flax fiber or other winding is damaged, which can rot and fade. In this case, the old winding is replaced with a new one, treated with paint or with a quick-drying varnish, which will allow it to withstand moisture and high temperatures.

- In addition, the nut may leak due to excessive movements of the battery or its branch pipe or the initial deviation of the thread axis.This problem can be eliminated, but before that it is necessary to turn off the heating by closing the valves. It should also be added that if the leakage goes along the thread, then the sweep will have to be changed.

- The same is to be done when rust appears. The last problem is eliminated by mounting brass parts that are unable to corrode or become covered with sediments. Operate the removal of brass can almost unlimited period of time.

Independent production

The shafts are usually made of steel, mostly galvanized. If the element is installed on an individual water supply, from which comes potable water, then brass and stainless steel are preferred. Experts note that the longest period of use can be seen in the stainless steel sgon. They assure that this material will last four times longer than carbon steel and twice as long as galvanized.

Sgon can also be made of bronze, copper and cast-iron pipes. Depending on the material chosen, the possible working conditions, and the service life and cost of the product will be determined.For example, copper sgon will not be exposed to temperature fluctuations and ultraviolet radiation. As for the price, one of the cheapest options is the aluminum element. Twice the price will have to be paid for a zinc component, and three times as expensive - for a stainless steel fitting.

Sgon is quite possible to make his own. Sometimes this is done to save time and money, and sometimes to compensate for the lack of detail in the store of the desired length. Usually, only the tube is made on its own, and the coupling with lock nut is taken from another set. When choosing a suitable material it should be remembered that the pipe should have walls of considerable thickness.

Consider the algorithm for producing sgon in the home.

- First of all, a blank of the required length is cut from the gas pipe of the required size. Grip the part in a vice, the processing of both ends of the pipe is carried out using a grinder, sandpaper or a hacksaw. It is recommended to pre-lubricate the surface with oil, its application will greatly simplify the process.

- Next, on both sides it is necessary to cut the threads: 20 - from one and 5-6 - from the other.This is done by screwing the plate with the guide frame into the pipe, and initially it is necessary to apply the maximum effort, and then everything will go by itself. You can stop pressing the plate after the first two turns. Cutting done in the forward and in the opposite direction.

- It is important not to forget to periodically remove the tool and clean it and the pipe from chips. After the initial cutting it will be necessary to carry out another one, fair.

Competently selected material and strict adherence to the instructions will help you to easily make a part of the desired size with your own hands.

For how to install pipe sling, see the video below.