How to choose a corrugated PVC pipe?

PVC pipe is a truly indispensable material, superior to other types of pipes in various applications. Plastic pipe has a huge number of advantages, while the disadvantages are extremely insignificant. Polyvinyl chloride (PVC) is a thermoplastic synthetic material from which a corrugated pipe is made. This product instantly became popular due to its undeniable merits and low cost. PVC pipe has the ability to withstand mechanical stress, while eliminating the risk of cable deformation. Due to the materials involved in the manufacture of corrugated pipes, the product is completely isolated from electrical current.As a result, the installation work with the use of electrical cable is absolutely safe.

Special features

As mentioned earlier, corrugated pipe quickly gained popularity. This product truly has an excellent price-quality ratio.

Let us consider in more detail the advantages inherent in this product.

- The corrugated tube is a non-combustible building material. If a fire occurs in the room, the product will gradually melt. However, PVC pipe has the property of self-extinguishing, in other words, prevents the increase of the flame.

- PVC pipes are windproof and moisture resistant products.

- Possess long service life, retaining its original appearance and characteristics for many years.

- The corrugated pipe is capable of withstanding enormous mechanical loads.

- The product has high dielectric strength. Two thousand volts is an indicator of the intensity of the electric field, with an increase in which the dielectric product conducts electric current.

- Polyvinyl chloride, from which the corrugated pipe is made, is highly insulated. Product resistance can reach a hundred ohm.

- High rates of environmental friendliness of the material and low rates of release of toxic substances into the environment.

- The plasticity inherent in a corrugated pipe makes it possible to give the product various complex geometric shapes and lay the pipe over long distances.

Of course, it is worth noting that this type of tube is an incomplete replacement of the communications system. And, like any other product, corrugated PVC pipe has several disadvantages.

Consider them in more detail.

- Polyvinyl chloride can not cope with sharp temperature jumps. Installation work should be carried out exclusively at ambient temperatures above five degrees Celsius. The maximum operating temperature at which the installation of a corrugated pipe is permissible is forty-five degrees Celsius.

- Corrugated PVC pipe does not tolerate direct sunlight, and therefore laying of this product outside the living space is highly undesirable. Exceptions are products with a reinforced structure. Electrical model with broach and flexible.

Such products are suitable for electrical wiring, for example, from plastic or plastic,and various electrical work.

Scope of application

The scope of the corrugated pipe is really great. And for each task it is quite simple to select the necessary type of corrugated pipe.

Due to its good plasticity, this product is suitable for installation in hard-to-reach areas, and the time spent on installation work is minimal.

- Electric supply system. The protective sheath of PVC products makes it possible to lay cables in the most hard-to-reach areas. Where there is a high risk of mechanical stress, for example, in mobile soil with high humidity.

- Telecommunication system. Corrugated pipe perfectly copes with the equipment of the local and main communication lines. For this purpose, a plastic pipe of small diameter into a larger rigid pipe is used.

- The use of corrugated PVC tube in the transport infrastructure. For example, equipment of cable sewers near railway tracks, highways, gas and oil.

- Often polyvinyl chloride pipes are used as a forming channel for power andinformation postings. This technology is used mainly in monolithic concrete structures.

- Another common application for corrugated pipes are utilities. For example, as a distribution network for street lighting sources and alternatives to the use of armored cables.

- A rare but still common area of use for corrugated PVC tubes is rainwater drainage. It is necessary in order to quickly organize and remove precipitations or melt water from buildings and institutions. PVC product in this case performs the function of a drain and removes melt and rainwater from the foundation of the building, pavement and lawn.

Requirements

In the course of construction work, in order to protect the cable from mechanical damage, polyvinyl chloride corrugated pipe manufactured in accordance with OKPD-2, GOST 50827–95 or TU 2248-002-18461115-2010 is used. Since the beginning of 2004, a new document came into force in the Russian Federation - GOST 32126.1-2013.

Like any other materials, polyvinyl chloride pipes have a list of certain technical characteristics, the manufacturer's compliance with which is extremely important.And their compliance with government regulations will allow the consumer to choose a truly high-quality product.

Let us consider these characteristics in more detail:

- raw materials are self-extinguishing polymer composites;

- color range is limited to gray palette;

- the recommended temperature for installation work is from minus five degrees to sixty degrees heat;

- the temperature at which the use of the product is acceptable - from minus twenty-five degrees to sixty degrees heat;

- The allowable mechanical load for a lightweight polyvinyl chloride corrugated pipe is three hundred and fifty N per five centimeters (at twenty degrees of heat);

- The allowable mechanical load for a super-heavy PVC corrugated pipe is seven hundred twenty N per five centimeters (at twenty degrees of heat);

- according to government regulations, the minimum dielectric strength is two thousand volts;

- The resistance of the insulation system of the product is one hundred million.

- fire resistance of the product reaches six hundred and fifty degrees.

Kinds

Today, there are three types of available corrugated pipes.

- Light polyvinyl chloride corrugated pipes (presence of a probe) - applicable exclusively when installing outdoor wiring in the room. This is due to the low resistance of the product to ultrasonic radiation.

- Heavy PVC tubes - are highly resistant to mechanical stress. Its use is permissible when it is necessary to lay the network of electric power supply underground.

- Super-heavy PVC pipes that can be used on a site with extremely difficult exploitation requirements. For example, this type of corrugated pipe is often used to protect a cable or cord, conducted by the underground method at a depth of one meter. This model perfectly copes with the most severe environmental conditions and mechanical loads.

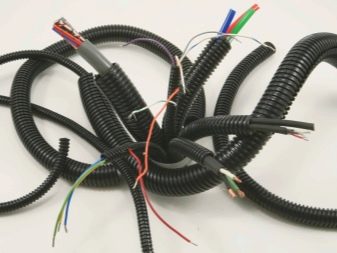

Lightweight polyvinyl chloride models with a probe make it possible to pave the system of communications and electrical supply at different angles and with many bends. Using such a collector, you can build an angle of up to three hundred and sixty degrees on the highway without the need to install an additional system and its re-equipment.This PVC pipe model can significantly reduce the cost of equipping the electrical supply network. It is also worth noting that a rigid collector with a ribbed shell meets all the high requirements for safe operation. In this regard, this product is often used to isolate electrical wiring in residential spaces. Lightweight corrugated pipes can be made with or without a probe.

The presence of a probe in PVC products is the most practical option. The cost of the product will be slightly higher, but you significantly reduce the time for laying the wire. A probe is a cord made of metal and fixed in the pipe body. With the probe, it is possible to quickly and easily lay the cable from one object to another. The lack of a collector significantly reduces the cost of the product.

From the advantages characteristic of corrugated pipes with a probe, it is possible to distinguish:

- low weight of PVC pipe, which significantly simplifies the laying of the product and eliminates the load on the supporting base;

- availability and low cost makes corrugated pipe extremely attractive for consumers building material;

- The absence of specific recommendations and strict maintenance of the product makes the operation easy and comfortable;

- high tightness and resistance to wind, dust and precipitation;

- environmental protection - corrugated pipe is an environmentally friendly product;

- long service life;

- incombustibility of the material;

- protective properties that allow to protect a person from electric current;

- plasticity of the material;

- high dielectric performance.

Dimensions

Corrugated PVC pipes today are presented in a wide range. The fundamental criterion when purchasing this product is its diameter. The standard diameter of the corrugation is sixteen millimeters. However, there are PVC pipes, the inner diameter of which is more than one hundred millimeters. And due to the absence of the risk of deformation of the wire and cable, such models will perfectly cope with the implementation of laying the underground power supply line. And also taking into account the high dielectric strength, in the event of a short circuit, ignition of the corrugated pipe is excluded. So, on the shelves of hardware stores you will encounter several sizes.

- Standard corrugated products with a diameter of 16 millimeters, for example, D20, D16. This option is the most appropriate option for laying the cable that will provide sources of lighting with electricity. Its use is admissible if necessary institutions from two to five wires, the cross section of which is one and a half or two and a half square millimeters.

- PVC pipe with diameters of 20 millimeters and more (assuming the presence of a probe) is suitable for the construction of electrical supply from the panel to the outlet or switch. Such a pipe can contain from two to five cables, the cross-sectional area of which is four or six square millimeters.

- Polyvinyl chloride product with a probe of 25–32 mm is recommended to be used to isolate the wiring that connects the distribution boards located in different rooms. It is worth noting that this option involves laying a backup tube.

- A corrugated model with an enlarged internal diameter of 40 to 50 millimeters is recommended to be used for the equipment of the cable connection assembly in a high-rise building. The diameter of the product allows you to simultaneously place from two to five wires, the cross section of which is from ten to seventy square millimeters.

- A product with a diameter of 20 or 16 millimeters (assuming the presence of a probe) allows you to build a trunk for telephone, coaxial communication and signaling system.

All PVC pipe products for cable insulation and low-current lines are manufactured in strict accordance with the standards specified in TU 2248-002-18461115-2010.

Tips for choosing

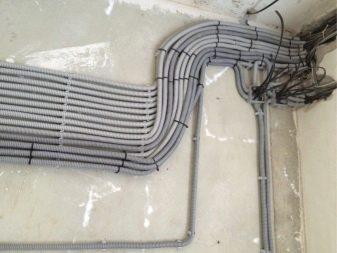

The acquisition of a PVC tube for cable is an important event that requires all seriousness and attentiveness. First of all, what should be determined is the diameter of the product. He is selected individually. This is due to the fact that the diameter of the pipe directly affects the indicator of the wire cross-section and their quantity. Another important nuance when purchasing a PVC pipe is the installation method. To date, there are two methods: open and hidden. The first option involves laying the pipe on the surface of the wall, floor or ceiling. For this method, the use of PVC products is permissible.

The second option is characterized by laying PVC products inside the wall, floor or ceiling. Concealed gasket is also called laying the product artificially.created space, for example, in a plasterboard wall or ceiling design. The use of PVC tubing is also possible. However, when planning to lay cables inside a combustible ceiling, the use of a plastic pipe is not recommended. The combustible floors are: wooden or other flammable surfaces, wood paneling or surface cladding with combustible materials. In this situation, it is recommended to abandon the use of PVC pipe, replacing it with a metal or electric-welded pipe.

The production of PVC pipes allows the use of specialized dyes, which paint the product in the desired color shades. It is worth noting that the coloring does not affect the performance characteristics of the material.

When using in construction several PVC pipes - you can use a single European standard for applying color.

- gray - general wiring;

- white color - computer networks;

- black and brown color - connecting electrical appliances;

- blue color - warm floor;

- red color - outdoor wiring.

Any purchase of the product must take into account the availability of a certificate of quality. This should not be a mere formality, but an important security requirement. A major role is played by the manufacturer, since most large enterprises value their status and do not produce low-quality products. One of the most reputable manufacturers of corrugated pipes are: Ekoplast LLC, Ruvinil CJSC, Delta LLC, and Nashorn.

For details on wiring in a corrugated pipe, see this video.