Important nuances of the selection of insulation for pipes

Presenting modern life without pipelines of various types is impossible. But in order for them to work efficiently, protection from the cold is required. And to solve this problem with heaters of the usual form does not always work, as there are subtleties and nuances.

Special features

Poorly insulated pipes can be broken when cold weather comes. This applies to plumbing, and sewage, and heating. If errors in the performance of thermal insulation of walls and ceilings only cause inconvenience, then improper selection of insulation for pipelines threatens with flooding, great material damage. There may be adverse health effects, deterioration of the sanitary situation (in case of sewage breakthrough), lawsuits and so on.

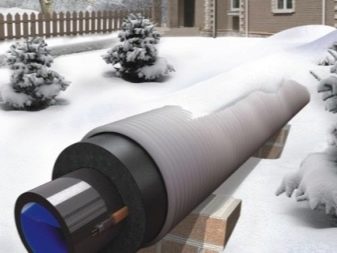

In this case, designs of insulation systems differ from those that are usually laid in the walls and floor. The reason is not only different geometry, but also the probability of contact with moisture. If the pipeline goes underground, a significant mass of soil presses against it. If it is laid in the capital structures of the house, mechanical effects are also likely. All this must be taken into account.

The role of thermal insulation is not only to reduce heat loss. It helps to reduce the depth of the pipeline under the ground or even stretch them on the surface. It is necessary to take into account only the difference to the insulating elements for underground and for surface sections of the pipeline route.

Selection of insulation is always aimed at extending the life of the protected highways. It is necessary to take into account the difference between the heating of the surface of the water supply system, heating, chimney, gas pipeline and sewage system.

Technical requirements

Consider the technical standards in each case simply will not work. Therefore, it is worth paying attention first of all to the toughest option - when the heating main is laid across the open area.

There are three motivations for doing this:

- connection of the remote centralized heating main and the building;

- heating with a separate boiler;

- transfer of heat from the main dwelling to other buildings on the backyard territory.

Immediately it should be said that professionals use the term "thermal insulation" and not "thermal insulation." After all, these pipes themselves are a source of heat, and it is important first of all to save it.

The larger the diameter of the pipe, the greater the heat loss. Therefore, only those materials will be suitable that best stop the heat loss. At the same time, a very important point is the hydrophobicity of the substance used.

Since structures on the street will invariably be exposed to precipitation, careful protection must be provided. If, however, the choice is stopped on a heater that absorbs water, you will have to additionally protect it from getting wet. The role of the outer cover is also to isolate the pipeline from ultraviolet radiation, from the load created by the wind. It is also necessary to take care that the insulation was resistant to destruction by animals, birds and vandals.

Summing up, it is easy to see that the main criteria for selection are:

- thermal conductivity level;

- experienced temperature variation at which the working capacity is maintained;

- operation time;

- resistance to negative factors of various kinds;

- ease of installation;

- safety for people.

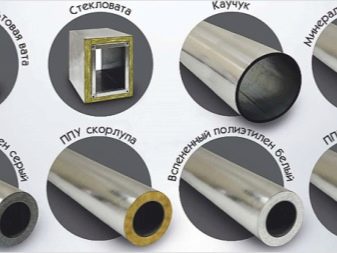

Kinds

Having formulated the basic requirements for pipe insulation, one can already consider its specific types - what they are. And it is best to begin the analysis with rolled structures, which are much more convenient than classic plates. Modern materials of this kind have enhanced practical characteristics, are excellent for pipeline components with the most sophisticated geometry. Most often in a roll there is mineral wool.

Its benefits will be:

- reduction of heat loss by several degrees;

- effective dampening;

- prevention of damage to the surrounding material by mold and other fungi;

- masking uneven surface areas.

The rolls containing mineral wool are long enough; they are excellent for thermal insulation of pipes in residential and non-residential premises. This material is excellent at intersections with ventilation shafts.Here the unique combination of flexibility and elastic properties plays a special role. Importantly, the roll passes less heat than a slab of wool of the same quality and thickness. This also applies to budget class models.

Atmospheric resistance and resistance to sudden changes in temperature will please most people. The attractive side of this decision is resistance to rodent attacks. Another plus is the wide variety of designs that are made from dissimilar mineral wool. You can choose the optimal solution for certain operating conditions. Insulation will be resistant to open fire, even when heated to 700 degrees.

The tubular structure can be protected by a simplified method. It involves the use of heat-saving paints or pastes. Such compositions contain acrylic and other substances. The advantage of this option is that it helps to further reduce the risk of corrosion. But reliability is often questionable. As the ability to resist destructive environmental factors.

The classification of the types of thermal insulation can also be made by the chemical nature of the substances used. They can be organic and inorganic, although there are also combined solutions. From organic materials, wood processing products, peat and straw-based products give good results. Inorganic insulation is obtained from molten rocks and minerals. Also in this category are the dregs of metallurgy and glass fiber.

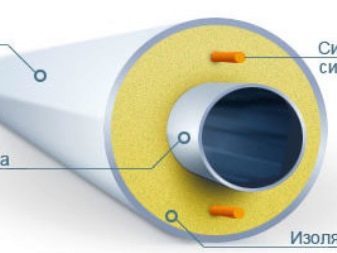

More cheap, but quite reliable thermal insulation is made of polyethylene. This material has excellent environmental properties and elastic, and modern technology allows to increase the stability of the shell. Smooth and resilient material can be supplied in the form of large sheets and tubular elements (the so-called merilon). Merilons are recommended to cover both sewage and water supply, including those laid more than 1 m.

Polyethylene blocks are equipped with perforated strips, thanks to which they are easy to install. Fastening is made on the construction tape, but this type of product is not suitable for pipelines laid outdoors. It is possible to cover large pipes with foam; but in order to use a “liquid” insulation layer, an insulating jacket will have to be applied. It is made of stainless or zinc coated steel.Difficulties may be associated with the complexity and trauma of installation.

One of the types of inorganic materials, mineral wool, has already been discussed. An alternative to it is glass wool. It comes in rolls of various sizes and finds application mainly in the protection of land communications in private housing. But it is used for this purpose and on large highways. Glass wool is famous for its long period of service, and even non-professionals can work with it.

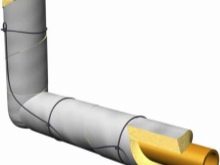

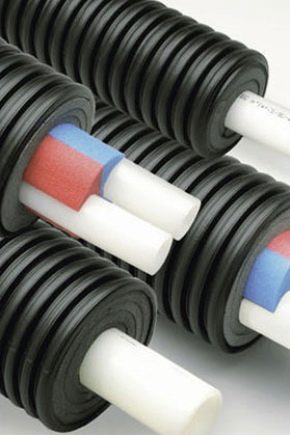

The most expensive type of thermal insulation for pipes is “shell”. It is used when it is necessary to protect pipelines of medium and large sections. "Shell" is made only in large plants. One layer is formed from mineral wool or from a sealing substance with the addition of polyurethane. Another make of thin sheets of metal or roofing material.

The outer surface of the material is similar in its relief to walnut. Fastening is made on the pipes divided into two halves. You can connect these parts with wire or special clamps. The "shell" is well suited for the most difficult areas - where the pipes are bent, turned or angled.

This type of insulation perfectly copes with the retention of a constant temperature inside the pipeline.

Additional benefits of the "shell" are:

- effective prevention of heat losses;

- Excellent heat energy savings

- perfect chemical resistance;

- lack of foreign odors;

- zero health risk;

- excellent resilience to significant temperature jerks.

Liquid heat protection is more profitable than “shell”, however, it costs more than mineral wool. We'll have to fill the gaps assembly sealants. You will need to very clearly calculate the consumption of foam. If mistakes are made, the sealant will either go beyond the space allotted for it, or will not provide adequate protection. The most popular variant of liquid insulation is rubber, which is pre-foamed.

This solution is recommended for the most critical pipelines. Foamed rubber is experiencing a good cold and heat, it will not catch fire and will not be damaged by ultraviolet radiation. The environmental, thermal and operational parameters of the liquid thermal protection make it possible to compensate for difficulties with its installation. Such tools are suitable for covering the pipes of air conditioners and refrigeration systems.An additional function of them will also be the containment of extraneous noise.

If you need to choose insulation for pipes with a cross section of 22/6 mm, you should look at the products under the brand name "Energoflex". The manufacturer claims that its products prevent not only freezing, but also corrosion processes and the effects of condensate.

Another firm claims that the appearance of the pipe will remain unchanged, that it will be well covered from contact with sunlight and pollution. Important: this insulation also helps to reduce air overheating, if a very hot liquid circulates through the pipes.

Scope of application

First of all, thermal insulation is used for heating, because there, along with preventing freezing, it helps to save an expensive energy resource. It is recommended to insulate pipelines not only outside the premises, but also inside, as well as in the boiler houses. After all, this will eliminate the energy consumption for heating non-residential rooms.

There are four main groups of insulating materials for heating communications:

- roll;

- cylindrical cut;

- cylindrical uncut;

- cylinder halves (the format is better known as "shell").

In any case, you need to calculate the installation of insulating structures for the exact diameter of the pipe. The appearance of the lumen significantly reduces the effectiveness of protection and may even lead to its failure. Important: slag mineral wool is not suitable either for heating or even for water supply or sewage. The service life of cotton insulation is relatively small (it reaches 10 years only with complete dryness and protection from mechanical factors). Foamed polymers are completely resistant to moisture and to significant cooling.

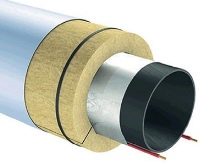

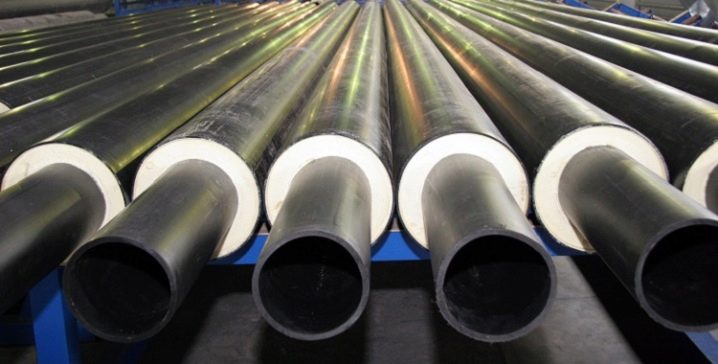

All polymers are characterized by increased flammability, which significantly reduces the scope of their application. If constructions made from them are put on large pipes, it is necessary to choose products with 3-4 locks. For small and medium pipelines, 2 locks are enough. Polyurethane foam manifests itself better than polystyrene foam, which is why it is recommended for the most important pipes. Insulators made of polyurethane foam, designed for heating circuits in homes, are supplied exclusively as strong shells with a steel sheath.

It is possible to apply PPU only with a reliable cover from the light. Foamed rubber, similar in characteristics, is recommended to a greater extent not for heating, but for ventilation pipes.

Not bad, he also shows himself to protect the pipes through which the cooling agent flows. Important: if there is even the slightest chance of rodents, you should use glass wool. All other substances, they gnaw faster than you can tell about it.

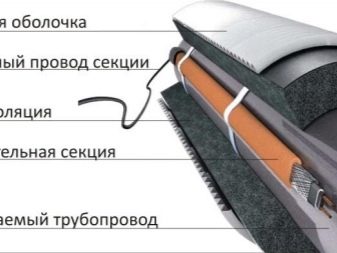

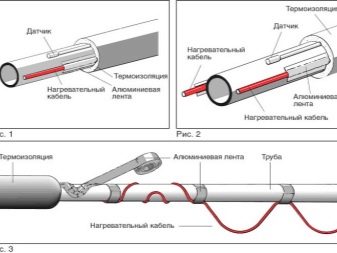

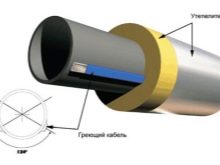

As for the water supply, it is necessary to insulate it mainly during the forced laying of pipes above the freezing line. Important: if the severity of the problem is weak, you can simply increase the speed of the water flow. This is done through the use of pumps or receivers. Also sometimes used heating cable. Cable heating is considered the most reliable and powerful way to protect against the cold.

This method is recommended for seasonally used cottages. The supply of heat through an electrical cable helps to quickly prepare the plumbing for use, and at the end of the need for it - to stop support.

The actual insulation is most often carried out through the use of rigid materials, these include:

- polystyrene foam;

- Styrofoam;

- penoplex.

Both the quality of protection and the cost are directly determined by the density. In the foam shell lay soft insulation to close the possible flaws and voids. Rolled insulation of water pipes is made of mineral and glass wool, furniture foam rubber, foil foamed foam. Problems may be associated with the hygroscopicity of the materials used. In addition to protection from harmful environmental factors, you will have to think about how to fix the roll on the pipe.

Professionals point out that plumbing is easiest to insulate with segmented materials. It is this option (sometimes also called the shell) that maintains the highest tightness and reliability. Another way to protect plumbing is spraying polyurethane foam. It initially provides absolute impermeability to water. The consumption of the component used depends on the thickness of the cast layer.

Selecting the option of warming water pipes, it is necessary to take into account the difference between the pipes laid under the ground and above it. The difference persists even when the same type of material is used. For plastic and metal pipes require different insulation.If you need to protect the plumbing on the street (under the houses, in the distribution wells), use any means that will maintain the necessary tightness and will not collapse under the action of water.

The overhead pipeline needs more protection than the underground counterpart.

The most difficult section is where the pipe rises to the surface. Here they use either the most powerful insulator, or lay out weaker variants in several layers. The cover of the main insulating layer from moisture is achieved by winding with plastic film or roofing material. If both solutions are unacceptable, form a plastic box. In any case, care is taken to minimize the number of joints, each of which forms a cold bridge.

You can solve the problem by laying out an insulating coating in the form of two mutually displaced layers. But it is not only the external parts of the water supply that have to be protected from the cold. Has its subtleties and cover tubes connected to air conditioners. The purpose of protection in this case is to preserve the unchanged performance of the climatic equipment. When using uncovered pipelines, a considerable part of the energy is consumed by heat transfer.Calculations are carried out in advance and the location of the air conditioner and all associated tubes are determined. When this is calculated, the required diameter of the insulating layer.

In most cases, the channels serving the climatic equipment are protected with synthetic rubber that does not have pores or foamed polyethylene. But the hygroscopicity of mineral wool prevents the use of it in this case. Where better to use mineral fiber with a water repellent layer.

Many pipelines in apartments and private houses are made of polypropylene structures.

The need to warm them occurs when placing:

- in the screed floor of the first floor;

- in the floor screed over unheated rooms;

- near the external door and window openings.

You also need to protect the polypropylene pipes included in the risers of water and heating. You can cover them with basalt cylinders. But it is quite an expensive material, which limits its use. More versatile foam.

Another advantage of this material is the ability to use it many times in a row.

Insulation of the aqueduct in the open air with glass wool is considerably complicated by the danger of its dust particles for the skin and respiratory organs. Prerequisite is the preparation of covers. All metal pipes, laid on the street, must be painted at the preparation stage. As for the insulation of sewage, it must necessarily be carried out in unheated rooms and in open spaces. The only exception to this rule are areas in which in winter the temperature is guaranteed not to fall to negative values.

Of course, in Russia this is only a theoretical assumption, since in reality there are no such localities.

In most cases, sewage pipelines, including those made from HDPE, cover up:

- mineral wool in various formats;

- polystyrene foam;

- expanded clay;

- polyurethane foam.

Occasionally used liquid insulating elements. All such options are considered passive species. But sewers, like other types of pipelines, are often protected with cable heating. Mineral wool to protect sewage systems should be used with caution because it contains formaldehyde resins and can break down under considerable mechanical stress.This greatly complicates the achievement of effective thermal insulation.

Cotton insulation is used when you need to cover the free sections of the channels. You can not lay them in the soil. Soaked cotton wool of any type loses its characteristics very easily. And if the pipes are made of metal, they often begin to rust rapidly. To install your own hands you need to use polystyrene foam.

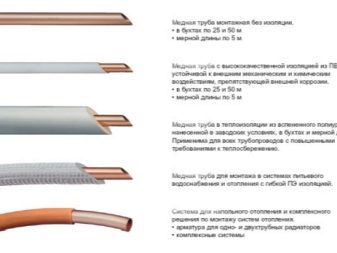

Engineering systems often include copper pipes that have impressive practical characteristics. But even they need effective thermal protection. In most cases, copper pipelines are covered with foamed materials. Such products are suitable not only for air conditioning ducts, but also for all water supplying systems, and for heating mains.

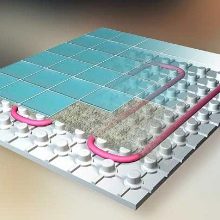

Thermal insulation is also important for floor heating. As the calculations show (and confirms the practice), the floors without insulation in an identical configuration, in similar conditions spend 20% more energy. Cork substrates are widely used to stop the heat flow. Their advantage is ideal ecological quality and excellent durability.For your information: cork has zero adhesion to cement screeds and blocks.

Installation of cork heat shield elements is possible if ceilings allow it. Cork inevitably raises the floor by 40-50 mm. Therefore, in rooms with low walls, it is unacceptable. Extruded polypropylene is considered the most popular method of thermal protection of a warm floor. The structure of its plates contains closed cells.

Polypropylene is well processed, it is not difficult to mount it, even where the floor configuration is very sophisticated. In addition, the synthetic material does not absorb water and can be used when heated to 130 degrees. Water heat-insulated floors are mainly protected with expanded polystyrene. Important: choosing a polymer structure, it is required to carefully study their chemical composition. Sometimes it contains toxic components that will be released during heating.

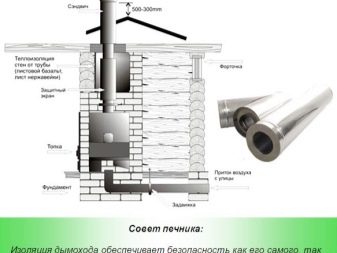

To complete an overview of the application of thermal insulation is appropriate for the protection of chimney pipes placed inside the walls.

To prevent heat loss and damage to the chimney with condensate help:

- mineral wool;

- fiber products;

- cinder concrete and structures based on it;

- brick battle;

- foam glass.

Under the ban naturally fall easily ignited and destructible under the action of heat materials. To use cinder blocks try professional builders. This option is quite heavy and requires careful design taking into account the load on the roofing and bearing elements.

For independent work, flexible and soft mineral wool is much better suited. Attention: irrespective of what, where and how it is insulated, it is necessary to take into account instructions for pipelines and for insulating materials.

How to choose?

As you might guess, the careful calculation of the diameter of the heat-shielding structures is of great importance. To determine the exact thickness of the insulating cylindrical part is very difficult. Sometimes you have to turn to professionals to eliminate serious mistakes. But there is a way to do everything yourself, you just have to turn to normal levels of heat loss. Such levels are fixed in SNiP and differ for each diameter of the pipeline, for each method of laying.

The calculation in accordance with a set of rules, including for pipes with a cross section of 32 mm, is much simpler than in accordance with the instructions of the technical literature of a professional level. Simplifications are connected with the fact that the heat consumption for heating the pipe walls is ignored.All the same, its real value is small, if we take into account the consumption of thermal energy for heating the external insulation. If pipes are made of steel, copper or cast iron, resistance to heat transfer is not taken into account.

It is very difficult to select a heat-shielding layer when the medium, heated to 300 degrees or more, moves through the pipe. Even those substances that can carry such a thermal load, pass a lot of heat. The total thickness of the insulating layer is sometimes excessive, because it is recommended to form a “layered cake”. Closest to the pipe have a material that stops the destructive effect of heat. Only after him create a different coating that prevents hypothermia.

When calculating and selecting, during the subsequent installation of insulation it is necessary to ensure that the temperature at the intersection of the layers does not interfere with the work of the external material. It is very important to take into account the degree of flammability of the chosen insulator. So, you can not apply heat protection categories G4 and G3 with gas pipes. It is not suitable for any pipes located inside the houses.It is recommended from the outset to be limited only to those materials that comply with the provisions of regulatory documents on a particular object.

From consumer considerations, it is easy to derive such selection requirements as:

- ease of installation;

- duration of use;

- affordability;

- pipe sealing;

- resistance to moisture.

Often these qualities are in conflict with each other. Then you have to give preference to the most significant parameters in a particular case. Polyfoam differs in small cost, it can be applied both in pure form, and together with external protection. Trays when laying material is not required.

But when selecting a specific batch of insulation, it is worth remembering that the shells must be mutually offset by at least 20 cm.

Polyethylene foam is recommended for self-isolation of water supply and sewage. Specific materials do not matter, you can even isolate the pipeline, assembled from disparate sections. Glass fiber, often sold under the name glass wool, it is advisable to use on plastic circuits with low initial thermal conductivity.But even in normal conditions of use, it is necessary to cover the isolator vigorously from exposure to water. Therefore, the profitability of such a choice is questionable, and the total time of work grows.

As for penofol, its advantage can be considered versatility - the ability to protect a variety of piping systems. Designs on this basis are easy to use. You can not say the same thing about polyurethane foam. Shells of it must be mounted immediately on the pipe, that is, the work is performed only by professionals. But it will be possible to avoid heat loss from the pipelines of any section.

Installation

When the method of thermal insulation of the pipe is chosen finally, it is time to install certain structures. Regardless of the type of protection they prepare it, trying to eliminate the emergence of “cold bridges” and uncovered sections. For insulation of pipelines located in unheated rooms and in the open air, the thickest insulation with a layer that stops the action of moisture should be used. Cylindrical mineral wool elements are used for lining pipes. Then these parts are attached using adhesive tape for winding.

Instead of scotch, occasionally take tapes and ties from plastic. If there is a risk of mechanical damage, it is worthwhile to install rolls coated with foil, glassine or folgoisol. Glass wool should be mounted only in working gloves, in tight, impermeable clothing. Ideally, in general, goggles should be worn. A small layer of wadded material is wound onto the pipes. Over it, a waterproofing shell is necessarily created.

When arranging the thermal protection of the "shell" it is only necessary to cover the pipe with suitable halves and attach them.

Overlay foil tape is made in the form of a spiral, it should go tightly pressed layers. The required overlap is achieved by shifting the first halves in relation to the second part. Having pressed the construction with scotch tape, we can consider the work completed by 100%. Similar technology is being worked out with foamed rubber, foam.

Differences appear when using polyethylene foam. It acts as a base for foil insulants. If there is no auxiliary layer, the product is damaged, gradually clumps, and soon its joint will spread.The work with sprayed insulation is completely different. For its spraying apply a special device and nozzle.

This option is suitable for inclined and hard-to-reach areas. But for underground highways it is inefficient. Anyway, the pressure of the ground mass will deprive this coating of valuable properties. Spraying does not present any particular difficulties for everyone who has at least minimal training. But if there is no experience at all, it is better to turn to professionals.

Otherwise, a lot of foam will be consumed, and a uniform layer will still not work. Experts recommend that you test your skills on a flat, easily accessible coating before you start working. When using a special paste based on acrylic and artificial fillers, it is necessary to take a spray bottle. Usually such a coating is applied in the form of several layers, then the insulation will be more reliable. At the preparation stage, it is recommended to apply a primer.

Regardless of the processing of pipes, it is required to evaluate the tightness of communication and remove rust if the pipeline is made of metal. Basalt cylinders are mounted on pipes using incisions in the longitudinal plane.Each branch, each knee and any bend is equipped with dialed parts. On sale there are integral parts, calculated at an angle of 30, 45 or 90 degrees. But you can independently cut the required elements from straight blocks.

Tie down cylinders with clamps. When the thermal protection outside has a diameter of 49 cm or less, steel wire with a zinc surface with a cross section of 0.09 cm is used. If the outer diameter of the insulation is 500 mm or more, special clamps will need to be used. As them they use tapes of metal or plastic, whose thickness is 0.04 cm, and width - 1.3 cm. The recommended gap between the two clamps is limited to 0.3 m.

In any case, the number of pieces of insulation should match the number of fasteners. Above the basalt insulation mount plastic layer to cover. Sheet entry should be 2.5 cm at each other. Attach external protective elements with plastic screws or non-ferrous rivets. Differences appear if the basalt cylinders have a foil layer.

Such structures can be connected with wire, steel clamps or tape with an outer layer with a metal surface.Important: the joint in the longitudinal plane is also required to be sealed with aluminum tape. The outer joints of the cylinders should close as tightly as possible.

Press and iron the tape on top of the insulation need a construction spatula. This is important due to the fact that the edges of aluminum tape are very dangerous when you touch it with your hands.

There are nuances when working with transverse joints. A pair of cylinders fit as closely as possible to each other. The smaller the gap separating them, the better. Again on the joint stick metallized adhesive tape. But now in the initial part reserve is reserved from 30 to 50 mm.

Pasting of the circle is completed by connecting the free ends of the tape with adhesive sections. 50-70 mm of tape should remain over the connected ends. Further, the connected ends should be bent along the joint and attached to the pipe. Both types of basalt insulation are mounted only at a temperature of at least 10 degrees. For your information: the insulating material must have the same temperature as the external environment.

When joining, it is impossible to press on the parts to be connected and create excessive voltage in them. Before fastening the basalt cylinders, it is necessary to dry and clean the surface.Much more often basalt is used from polyurethane shells. The perimeter of the half-cylinder is covered with locking joints with grooves and spikes. Such connections need to be used to get rid of cold bridges.

Foil, polyethylene film, fiberglass or polyvinyl chloride is used for external protection of polyurethane foam. Heat protection in this way can be created regardless of the season. The only requirement is the limited humidity of the environment.

Unacceptable surface contamination:

- unnecessary items;

- lubricating oils;

- bitumen;

- fuel;

- household mud.

Processing of anti-corrosion compounds before installing the foam should be made in any case. Bonded surfaces are covered with specially selected glue. Warning: universal adhesive mixtures are undesirable.

Many of them are too aggressive chemically and corrode polymer components. If lengthy blocks are used, clamps are used in the middle of them; sometimes put two or more clamps, the distance between which is 1 or 2 m.

Tips

In some cases, the surface of hot pipelines is insulated by spraying asbestos perlite and specialmastic. Such a solution is used only at the operating temperature of the insulated structures themselves. The fact is that the temperature drop can disrupt the normal operation of thermal protection. Foam plastics can be used to protect underground heat networks. The highest operating temperature is 150 degrees.

To minimize the complexity of the work, you can use pipes that have been applied to the phenolic foam during production. Such constructions are allowed to be used for non-channel type heating networks.

Another option involves the use of a combination that includes:

- asbosurite;

- asbotrepel;

- sovelit.

One part of the solid components accounts for 3.5 parts of water. After mixing and dissolving, asbestos is added. At the same time achieve that the mastic, uniform in structure, was created. Its application should be made on galvanized steel mesh.

The method of attaching the mesh is determined by the material of the pipe itself, for fixing use:

- studs;

- tightening rings;

- bandages;

- clamps.

Fasteners must be sized to achieve the greatest rigidity. They set the total thickness of the insulating layers.The first layer uses a maximum of 0.5 cm of material. When it dries, form the main insulating layer. The main line of thermal protection is created in one or several techniques.

The final layer of mastic insulation should have a thickness of 0.5-2 cm. The consistency of this layer should be very thick, and it is necessary to apply mastic when the bulk is still not frozen to the end. The finishing layer is designed to align the surface of the insulation. It is allowed to apply mastic both manually and using pneumatic devices. When the insulation dries, they put on it the fabric you want to dye.

The choice of mastic insulation is justified by the simplicity of their use, solidity of the formed protection and the ability to prevent heat leakage from surfaces of various geometric shapes. But we must bear in mind that this type of coatings fit with great difficulty and requires a large investment of time. In addition, mastics are characterized by insufficient stability of their characteristics. Therefore, it is recommended to use a similar insulation applied in industrial conditions. If mastic insulation is formed in places where it can be affected by vibration, outside air or mechanical defects, metal covers should be used.

When you need to achieve impressive thermal parameters at the same time with solid strength and considerable flexibility, you should choose mats based on ceramic fibers. It is initially a ready-to-use type of thermal insulation. On the production process it is treated with the help of special machines, punching with needles perpendicularly. For the firmware uses the same fiber. The advantage of ceramic blankets is that they are able to survive the heating up to 1400 degrees, while maintaining decent tensile strength.

It is undesirable to use fiberglass for thermal insulation of underground pipelines. Even an affordable price does not justify excessively rapid wear. But for above-ground structures such a solution can be safely considered. It is impractical to use for the protection of pipes laid underground and foamed polyethylene, the joints of which can easily diverge. Even with little mechanical stress, it is prone to large shrinkage.

Often there is a statement that it is worth using insulants of the maximum possible thickness, even more theoretically calculated values. However, this is irrational, because it entails only unnecessary costs.When installing both underground and ground insulation blocks, the natural shrinkage of thermal protection should be taken into account. To enter the necessary amendment, you need to know the coefficient calculated for a particular material.

We must not forget about the consideration of the mechanical load. The system of fasteners must take all the impacts harmoniously distribute them. If there is no such construction or when designing it, mistakes are made, weakening of the heat-shielding qualities is almost inevitable. When you need to definitely high-quality and the easiest to work in insulation, and the costs do not matter much, you should give preference to basalt elements.

In the next video you are waiting for the rules of thermal insulation of pipes and branches with sheet material.