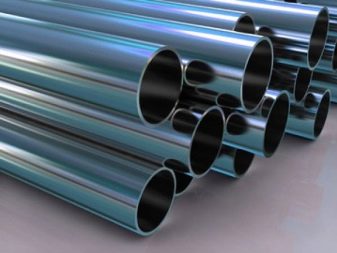

Galvanized pipes: the rules of choice and installation

Galvanized pipe is a product of the pipe-rolling industry, which has received for its resistance to destructive factors, widespread in all areas of economic activity. Products are manufactured in a different dimensional format, according to different rolling technologies that determine their characteristics and cost, and in addition, using different galvanizing technology, which also contributes to the properties of the final product - galvanized pipe.

Special features

Galvanized steel in the manufacture of pipes came to replace steel with “black”, after it became clear that with all its strengths, “black” steel has a significant flaw - the susceptibility to corrosion, due to which the durability of such pipes significantly decreased.In general, the performance properties of stainless steel products are similar to the "black", but they also have distinctive qualities.

Characteristic features of stainless steel pipes include:

- high thermal conductivity;

- no temperature limitation for the transported liquid / gas;

- resistance to high pressure;

- relatively small expansion during heating, good metal memory - after cooling they take the same shape as before heating;

- high density of the material;

- excellent strength;

- durability of the structure;

- positive effect on water quality, preventing the reproduction of any microorganisms;

- resistance to any environmental influences, excellent resistance to corrosion processes;

- the appearance is not the most presentable, and with mechanical effects on the surface it becomes even worse;

- more expensive "black" steel.

Longitudinal galvanization of metal pipes for water supply and the duct has a long service life.

To extend it, you can additionally paint the product and lay the insulation.

Kinds

Galvanized pipes are divided into many parameters, each of which can be significant depending on the tasks. Consider all the classifications in detail.

To destination

Depending on the main standard and the technology by which the galvanized steel pipe is manufactured, its basic qualities and operating conditions are determined. There are several main types of pipes.

Water pipeline

High quality product, the production of which applies GOST 3262-75. It has a dual purpose: water and gas systems located in enclosed spaces. The standard format of such pipes determines their length in 4–12 meters.

Separately, you can highlight such features of products:

- good anti-corrosion performance, exceeding the "black" counterparts by 10 times;

- convenient installation, perfectly amenable to cutting, welding and molding;

- the long operational term reaching 25 years;

- manufactured according to the average and increased accuracy class, the first is used for gas and water mains, as well as heating systems, the second - for the manufacture of parts;

- have thicker walls in comparison with the "black pipe";

- at the same size, they are lighter than “black” pipes.

Electrowelded

It is made of steel in accordance with standard GOST 10704.Areas of application are: engineering, agriculture and the construction of non-critical structures. The length of the products is the same as that of the water-gas pipeline - 4–12 meters with the diameter can be from 110 to 480 mm.

Available in two basic versions:

- with cut edges and fins removed;

- with a simple cut.

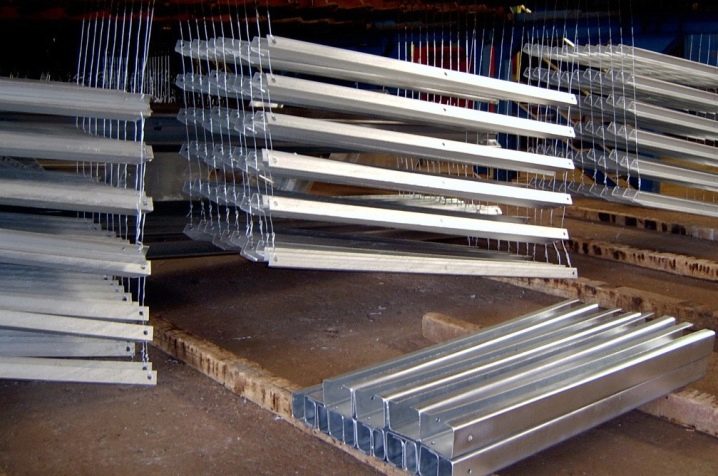

Profile

The main difference is the section shape, close to a rectangle, but with rounded corners. The main GOST of manufacturing 13663-86. Also GOST 8639-62 for square variety and GOST 8645-68 for rectangular are used. The length of the sides of the product ranges from 10 to 50 mm. It is subdivided into two subspecies according to the thickness of the walls: thick-walled and thin-walled. In addition, the profile galvanized pipe is inherent: strength, durability, relatively low weight and resistance to corrosion.

Seamless

Universal view, can be used in almost any sector of the national economy. For the production of high carbon or alloyed steel. It has high durability, but due to the complicated manufacturing procedure, their price is also higher.

In addition, such characteristic features of seamless pipes can be noted:

- guaranteed no leakage;

- high resistance to mechanical stress;

- resistance to aggressive chemical compounds.

By scope

Depending on the scope of use, galvanized pipe can be divided into the following types:

- plumbing;

- gas;

- for heating system;

- for domestic needs;

- household purposes.

By galvanizing technology

In addition to the main technology involved in the manufacture of rolled products, the galvanizing process is further applied. There are several different methods, each of which introduces its own specificity in the operational properties of the pipe. There are three main methods: electrogalvanic, hot and thermal diffusion.

Also in the process of processing, depending on the purpose, galvanizing can be applied only on the inner or on both sides of the pipe.

Electro Galvanizing

In this treatment, zinc electrodes dissolve in the electrolyte under the influence of electricity and are “welded” to the pipe surface during electrolysis.

This method is widely used and has the following advantages:

- uniform surface coverage;

- good appearance;

- zinc layer thickness up to 30 microns.

The disadvantages of this technique are:

- low adhesion of zinc coating;

- short service life - up to 5 years, as a result of the high porosity of the coating;

- production waste has a high disposal cost and can harm the environment.

Hot galvanized

The technique allows to produce galvanized pipes with high adhesion of zinc coating. The manufacturing process consists in dipping a “black” pipe into molten zinc.

The main advantage is the strength of the zinc coating, accompanied by a number of disadvantages:

- high production cost;

- the surface may have sags that require additional mechanical processing;

- Steel with a carbon content not exceeding 0.24% may be used for the manufacture.

If necessary, pipes with high durability and resistance to vibration, the existing flaws are not critical.

Thermal diffusion galvanizing

This technique determines the low rate of production of zinc pipes.The process consists in the treatment of "black" rolled products by means of zinc vapor in sealed chambers. This feature determines the least harm to the environment among all methods of production of galvanized pipes. Products obtained by thermal diffusion galvanizing are of high quality.

In addition, we can distinguish such characteristic features of such processing:

- high hardness of the surface layer;

- the technique allows galvanizing only one side of the pipe, which makes it possible to reduce the cost of products for operational features that do not require anti-corrosion properties from the outer layer, for example, for chemical plants;

- clean surface without sagging;

- pipes that have already been machined by other methods, for example, threaded;

- welding works minimally damage the adjacent zinc layer;

- operational term more than 15 years;

- relatively high cost.

You can also highlight two techniques that allow galvanizing steel pipes already installed:

- Cold galvanized. The method consists in applying a special solution to the surface of the steel, that is, in fact - it is painting.The operational period of coverage reaches 5–6 years, but it is highly vulnerable to mechanical stress.

- Thermal galvanizing. It consists in applying zinc powder to the pipe by means of flame spraying. The coating retains suitability for 7–8 years, but the resistance to mechanical stress is also low, and in addition, the layer is characterized by high porosity.

Dimensions and weight

Galvanized pipes of the standard (standard) version are produced with the following external radius and a weight of 1 linear meter:

- 17 mm, 0.98 kg;

- 26.8 mm, 1.66 kg;

- 33.5 mm, 2.39 kg;

- 42.3 mm, 3.09 kg;

- 48 mm, 3.84 kg;

- 60 mm, 4.88 kg;

- 75.5 mm, 7.05 kg;

- 88.5 mm, 8.34 kg;

- 101.3 mm, 9.6 kg;

- 140 mm, 15.04 kg;

- 165 mm, 17.81 kg.

In this case, the length of the product reaches from 4 to 12 meters.

Scope of application

Galvanized pipes are used in almost all areas of human activity. They are most common in the housing and communal services when laying pipes for water supply, heating and gas pipeline systems. Highways of galvanized pipes, given their high resistance to corrosive processes, can be laid both in the open air and underground, any sources of moisture are not afraid of them. In addition, columns of outdoor lighting are made from such a pipe.And for plumbing and fire systems, products with reinforced welds are used.

Also galvanized steel is used in the arrangement of roads., supports for traffic signs, streetlights, road and bridge fences are made from it. In open air conditions, the ability of galvanized pipes with a coating thickness of more than 30 microns to withstand high humidity is just what we need. In addition, galvanized steel is used in construction. Pipes are used in the construction of industrial premises, pavilions for various purposes, warehouses, repair shops, sheds and other light structures that are in contact with moisture directly. Also galvanized pipes are used for installation of air ducts and ventilation systems. In the infrastructure for the creation of public transport, children's and sports grounds.

In the agricultural industry, galvanized pipes are used in elevators, greenhouses and greenhouses for water supply, and in plant growing - mineral fertilizers and watering. Zinc perfectly resists alkaline compounds and moderately acidic environment.In the garden of galvanized steel make support for young trees and grapes. In animal husbandry, it is used to make supports for barns, chicken coops, stalls, and other premises for livestock. Here, zinc also exhibits better properties, resisting the ravages of animal waste. Galvanized steel serves twice the "sulfur" and at the same time does not require maintenance and repair, which also reduces operating costs.

Seamless rolling for excellent performance is applied at critical sites in areas such as oil and gas transportation, at nuclear power plants, in aircraft manufacturing, monolithic construction, in mining or drilling of minerals.

Installation

When installing galvanized pipes, several basic methods are used to connect the products together. These include various techniques.

Threaded connection

It is used on round galvanized steel with thermal thread diffusion zinc plating. Couplings, nipples, gearboxes, plugs, adapters are used to connect such products. In compaction of the joint they use hemp with staining.If the rental is hot dip galvanized, the threads will have to be further processed. Pipe joining by thread is performed according to a standardized method and is distinguished by high quality, reliability, tightness, no leakage and corrosion processes and allows for replacement and repair without complicated dismantling works, for example, cutting.

Welding connection

It is used relatively recently, previously due to damage, nearby sites, zinc coating high temperature was not used, as they became vulnerable to corrosion. It is also worth noting the harm of zinc vapor to humans, which complicates the work. For welding of galvanized pipes, a protective layer of flux is used, which protects the zinc coating from high temperature.

The weld is formed from the melted filler rod, the zinc melts, but does not fade, and then freezes again. This method boils pipelines, remaining inside the flux is washed out over time, without causing harm to water quality. Another technique involves the use of food carbon dioxide as protection. It is used while working with a semi-automatic.

In this case, the zinc layer surrounding the seam is trimmed from the negative impact of the welding process, of oxides produced by it. Using gas-electric welding to connect thin-walled galvanized steel, craftsmen also use copper rings, which, after the process is completed, are removed without disturbing the zinc layer.

Flange connection

The method consists in mounting on the ends of galvanized pipes of special fasteners - a flange, which are interconnected by bolts.

With this type of connection, it is imperative to use a rubber seal.

Installation of smoke exhaust system through galvanized pipes

This process is technologically simple and consists of following several successive steps. Special skills are not required, but familiarization with the details will save time and materials.

You need to do the following:

- Chimney segments are connected to each other starting from the bottom piece.

- In the process of assembling, it is necessary to immediately determine where the inspection doors will be for cleaning the chimney in the future.

- With an interval of half a meter, the chimney is fixed on brackets or mounting clamps.

- In the place of passage through the ceiling of the floor and the roof, a special chimney passage node is installed.

Tips

When working with galvanized pipes, it is necessary to consider not only the basic rules and regulations, but also small subtleties that affect the final result. Galvanizing is necessary to choose quality. For reliability, you can wear a casing.

Galvanized pipes, except seamless, do not withstand high pressure. For work in water supply systems, the maximum indicator is 16 bar, for pneumatic systems - 10 bar.

Contrary to prejudice, galvanized pipes are excellent for water supply systems and are not harmful to human health. With a constant filling of the water main of the MPC of zinc from the pipe surface does not exceed 5 mg / l, while the norm for the human body is from 10 to 15 mg / l.

The excess of the normal content of zinc in water is determined by a person by its viscous taste.

About galvanized pipes, their effects on health and modern plumbing, see the following video.