Replacing pipes in an apartment: damage diagnostics and installation recommendations

To change pipes in city apartments it is necessary quite often. It is important to know when it should be done, how exactly, and what is better not to do at all. Let's try to understand this issue.

Evaluation of the state of communications

Determining the real state of communications in an apartment cannot be limited simply to their visual inspection and comparison of the current state of affairs with the project. Be sure to ask anyone who may have information about the problems (including neighbors) and consult with the service organization. Professionals always write in their conclusions whether the distribution of water supply in a new building or an old house is in line with the provisions of the joint venture 30.13330.2012 "Domestic water supply and sewerage".It is necessary to check not only the pipes themselves and the sanitary equipment connected with them, but also water meters.

Sometimes the water supply of a microdistrict or individual houses is organized with the help of not a centralized water supply system, but a casing well of various depths. This source is also required to be periodically monitored with the involvement of professional performers.

During the test, the following standards are established and verified:

actual location and dimensions of individual parts;

diameter;

perforation intervals;

the presence of deformations in the cement;

quality of the filter.

To perform such a survey help specialized measuring and control devices. More relevant for people problems with the functioning of the toilet or a closed heating system of the apartment. Many houses still have many old pipes installed 25-30 years ago and more. During this time, any metal grade to a certain extent loses its characteristics, internal channels are overgrown with sediments, fistula, corrosion and even leaks appear.

With all these problems, a repair must necessarily be carried out, but it may be different in scope, respectively, and in terms of funds expended.

Reasons for replacement

With all the care of designers and installers of pipe communications, they have a sad tendency to fail. It sometimes happens that it’s impossible to restore the working capacity of a water supply system or sewage system without changing its components drastically. This is especially true for risers laid during the period of mass housing construction and a little earlier. Then mainly cast iron and steel with zinc coating were used for the production of pipes. Under the action of various substances dissolved in water, suspended solids and due to the corrosion process, leaks inevitably appear over time.

Prolonged use of metal water pipes is bad in that they can not just clog and leak a little water. A more serious threat is a breakthrough in communications with the flooding of one’s own apartment and all apartments below. The stand-up of the hot contour is especially often affected, because it is experiencing an additional thermal effect. The need to replace the water supply system arises if its expiration date has expired or the apartment is overhauled. According to the standards generally accepted in the construction environment, metal water supply risers should be operated for an average of 25 years.

About 15 more years their use is only permissible if immediate replacement is extremely difficult. But the use of pipelines, mounted more than 40 years ago, is impossible in principle. Breakthrough and flooding can be expected at any moment. As for major repairs in the apartment, replacement of the risers is justified by the fact that they are laid with decorative materials, overlapped with furniture and accessories. If you do not replace them immediately, without waiting for the warranty period to expire, you will have to break the created structures and re-create the decor.

It is recommended to change the riser from the bottom point of entry into the apartment to the ceiling. If you limit the elimination of blockages or rust in a short area, changing it in isolation, you can face additional problems during operation very soon. Experts advise to change the pipe even in the most "heavy" points of overlap - it is there that wear occurs quickly and violently. It doesn’t matter where the replacement will take place, in the kitchen, in the bathroom or combined bathroom - you should definitely coordinate the work with the organization operating the house and turn off the entire riser.

It is advisable to take on the replacement of pipes made of modern materials that will last much longer than outdated cast-iron or galvanized structures.

Selection of materials

But there may be another difficulty - on the market there are many options for materials and designs of them. Manufacturers and sellers, of course, claim that it is their product to take the best, that it will reliably cope with the task. The choice is further complicated by the fact that under the common name plastic pipes realize the most different types of polymers. Polyvinyl chloride elements that have proven themselves in other industries have become quite widespread. But for pipelines, the same substance is not used as for windows or doors; it is necessarily modified by introducing special additives.

Because the recipe, which adheres to a particular manufacturer, pay special attention. Hard PVC can not boast of flexibility during installation and subsequent operation.

But it also has obvious advantages:

increased stability with strong heat;

excellent impact resistance;

wall strength;

eliminated the destruction of the onset of cold.

If you use such pipes for sewage, they will cope very well, because they are designed for industrial endurance class to saturated solutions of fat in water, to organic and inorganic acids. In a city apartment, in contrast to a private house, there is no place for non-pressure pipelines. Many experts believe that it is better to choose polypropylene pipes, which have managed to establish themselves from the best side in recent decades.

Their advantages are:

suitability for hot water circuit (high quality polypropylene becomes fragile only at 140 degrees);

much higher than the best grades of steel and cast iron, corrosion resistance (can be installed even in areas prone to flooding);

zero risk of propagation of stray currents or contact voltage through pipes;

increased wear resistance even with relatively dirty water.

The latter circumstance does not mean that you can completely ignore the need to install filters. After all, even if the pipe can withstand pollution, a plumbing fixture may be affected.“And there are spots on the sun,” and polypropylene has its fatal weakness - it is not friends with the Sun itself. The rays of the daytime luminary will quickly spoil the material, it will lose its strength. It is important to remember and to be careful when installing, using such pipelines, accidental hammer blow or strong pressure can damage the fragile contour.

Another popular option now is polyethylene. Other polymeric materials can not be compared with him in flexibility. Polyethylene pipelines are lightweight and can be designed without unnecessary problems even where other designs fail. The classic polyethylene pipe is designed only to pass cold water. To post a hot fluid, you need to take a special kind of this material or even consider other options. Low-pressure polyethylene is much better than that obtained at elevated pressure, because it is mechanically stronger.

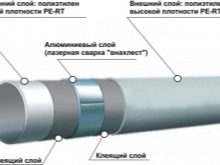

Complete a review of synthetic materials is appropriate for pipes made of metal. This is a whole "cake" containing several layers. Water itself washes the wall of polyethylene food category.Behind it is placed a layer of aluminum foil, which gives the assembly rigidity. And the outer shell is also formed from polyethylene, but already having an increased density and rigidity.

So that the layers do not move chaotically in different directions, they are bound in the production with a special compounding glue. In terms of resilience to corrosion processes and resistance to cold periods, metal-plastic pipe is a worthy alternative to simple polymers. Moreover, it can bend in an arbitrary direction, which is very useful for installing pipelines in narrow, hard-to-reach places or, if necessary, create a bizarre configuration. Metal-free plastic transfers heat up to 95 degrees, while the pressure inside the pipe can reach 10 atm. If there is a flow of fluid through it, heated to 25 degrees, the permissible pressure is also 25 atm.

No matter how hard the creators of synthetic materials try to create universal types of them, traditional metal constructions occupy their niche firmly anyway. Gradually, the popularity of copper pipes manufactured without a seam increases.No polymer, no steel grade provides the necessary reliability. If you take two pipes - one of copper, the other - of steel, with an internal cross section of 1.2 cm and a wall size of 0.1 cm, then at a flow temperature of 250 degrees the steel will withstand a pressure of 100 bar, and copper will remain stable even at 600 degrees and 500 bar. Another significant advantage is that as the temperature rises, the copper pipe only increases the mechanical strength, and at the same time plastic qualities.

Therefore, experienced specialists know that it will survive threefree freezing and thawing without unnecessary consequences. Such an extreme test will not cause even the loss of consumer characteristics. Breakthroughs on copper pipelines, with comparable destructive force, always cover the minimum distance. If a steel pipe bursts, the cleft quickly spreads, even sometimes it has time to cover the entire length of the pipeline. The disadvantage of copper can be considered that it does not make the preparation of the thread and is mounted only with the use of fittings of the combined scheme.

It will not be possible to use the copper pipeline where:

fluid flow moves faster than 2 m / s;

water contains solid inclusions that can affect the walls;

the stiffness of the flowing fluid is lower than 1.42 or higher than 3.42 mg per liter, the acid-base balance does not fit into the corridor from 6 to 9.

Even cast iron pipes have their advantages, especially since they are not produced from the usual brands of cast iron. Those are too fragile and would have an extremely small resource. In plumbing and sewage, an alloy is used, modified by the introduction of magnesium and further annealing at high temperatures.

The change in the structure of graphite that occurs during such processing helps:

avoid a hint of fragility;

radically enhance immunity to oxygen from the atmosphere and other aggressive agents;

to provide stretching under deforming load without cracking.

External differences between plumbing and sewage pipes made of cast iron no. If you require maximum anti-corrosion properties, it is worth taking a product with a coating of bitumen. The connection of the pipeline fragments is made by inserting one pipe into the socket of the other and sealing the joint with the help of a “hook”. Geometrically complex configuration is formed by additional elements.All cast-iron pipes are used mainly outside the apartments, on highways, because even their improved versions are not very convenient.

Necessary tool

But the material was finally chosen, the components were purchased and even stowed in anticipation of the start of work. It will be very good if by this moment all the tools that are required to be used for pipe laying will be available. Since most people clearly prefer polypropylene, it is worth analyzing the treatment with it. Cutting fragments of the future plumbing, sewage or heating is best done with specialized scissors for plastic processing. If they are not turned out, you can not rush to the hardware store, and use a saw on the metal (only then removing the burrs with a file).

Pipes connected to fittings must be chamfered beforehand. Failure to do so may result in deformation. It is easy to remove the chamfer even with a simple kitchen knife. Also, this manipulation is done with sandpaper. It will fix the problem at either end of the pipe in a matter of seconds.

More difficult is the situation with the stripping of pipes, which are equipped with aluminum foil. They are cleaned only with a specialized tool. When cleaning is done, you need to use a special soldering iron. In addition to the holder and the heating block, it also contains alternating nozzles that allow to supply heat simultaneously to the pipe and to the fitting.

Replacing the nozzles is important because each is designed for a specific diameter.

Docked pipes, you need to attach them to the wall. For this purpose, plastic clamps are used, held by standard screws. You can confine yourself with a screwdriver and a screwdriver only when working on wooden walls, and also when bars or steel profiles with galvanization are used as a support.

To fix the pipeline to the brickwork or fasten it to the concrete, you will need:

perforator;

drill out of the win;

hammer;

knife with a sharp blade;

the same screwdriver or screwdriver.

Connection to valves and other parts of the valve is made with an adjustable wrench. Sometimes sets of open-end wrenches are also useful. Using all the above tools, you can securely fix the mixers to the pipes.In some cases it is required to reel the connections in order to increase their tightness.

The best material for this purpose is flax with the introduction of fast-drying pigment.

Dismantling

But since this is not about installing pipes from scratch, but about replacing them, you must first dismantle the old pipeline circuits. Dismantling the water pipes with their own hands is not particularly difficult if you know exactly how to approach it. The key requirement is to reduce the impact on the indoor environment. It is necessary to think in advance how to circumvent spatial constraints and how to extract extended pipe sections. Plumbing begin to remove by removing or cutting fittings.

If possible, try not to use gas cutting. Failures with the removal of the fitting are almost always overcome by warming up with a building hairdryer. But you can do without a hair dryer, just lightly striking the fitting with hammers, because the vibration weakens the part holding contamination.

With all these manipulations, the pipe must be supported by a key so as not to damage unnecessary fragments. Sewer pipes are usually removed without wrenches, because they are joined using seals and sockets.

But if the sewage system is made of cast iron, for the most part it is placed in a layer of cement or sealant. Removing brittle cast iron from this hard shell is not at all a trivial task that requires care and accuracy. When working using pry bar and chain keys. If the cast iron element to be removed is much longer in length than the space that can be used for turning, it is necessary to break it. It is much easier than trying to cut the iron; destroy it best with a sledgehammer.

The pipe is covered with a cloth in advance, this will help prevent the scatter of fragments. It should be borne in mind that the pieces are very sharp and you need to be careful with them. The dismantling of the fan pipe has its own characteristics.

If it is made of cast iron, it is necessary to seek help from specialists. Attempts to independently perform such work threaten the integrity of the sewage system and other serious consequences, including the complete replacement of the riser.

Sewage pipes from simpler materials are dismantled by hand. In addition to the drill, you need a sledgehammer and angle grinder with a set of both working and ground discs.The sewers are shut off in advance, while all the upper tenants must not open the taps for some time and do not flush the toilet bowls and bathtubs. Having received their consent, they begin to disconnect the pipes. This will require considerable physical strength, and therefore you should still think about attracting specialists.

Repair methods

Water pipes

In addition to the peculiarities caused by the specifics of the materials, the type of serviced communications also affects the course of the installation work. Thus, the installation of a new water supply system instead of the old one implies the least change in the interfloor zones of the risers and the layout of the apartment. In advance of studying the specifics of all materials, familiar with the technical and spatial parameters of plumbing. It is necessary to take into account how the installation sites of sanitary fittings will be arranged, what auxiliary devices will have to be installed.

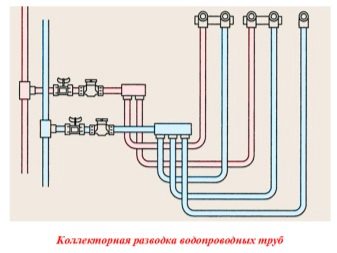

Some equipment (washing machines) absorbs only cold water. But boilers, mixers and boilers require two inputs at once. Collector wiring is recommended for apartments of a large area, it is especially good when there is one riser, and the distance between the water points is large.Such a solution ensures optimum results in head and water flow for all devices. The connection is made through autonomous branches, which are diverted from the collector node.

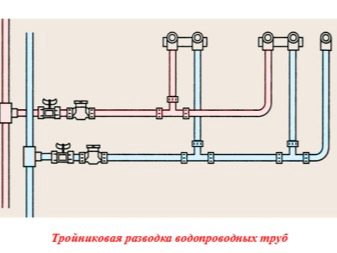

But the advantages of such a scheme are overshadowed by the fact that its implementation requires a significant amount of materials. In addition, a lot of tube bundles are extremely difficult to lay on an open pattern, and even create a beautiful view. The exit turns out to be a hidden method of installation, in which communications are hidden in the floor or closed with decorative structures. Until recently, the only way to organize the water supply in the apartment was tee distributing. It has only a couple of branches - hot and cold water supply, and it is this simplicity that most attracts the attention of people.

The connection of equipment in this scheme is carried out sequentially. The number of materials used is small. The installation according to the triple scenario is useful if it is necessary to replace the failed emergency pipelines as soon as possible. It allows you to do without violating the integrity of the finish.But there is also a weighty limitation, it consists in the expressed inequality of water consumers according to its pressure and flow stability. To some extent, this is offset by a reduction in the diameter of the distant tubes and the transformation of a straight line into a ring.

More accurately choose the diameters of the pipeline can, if we take into account:

how long branches are created;

where what peak pressure is planned;

other factors familiar to experienced installers.

Sewage

But even the most reliable and smooth running water supply system will not cope with its task, if it is not complemented by a properly executed sewage system. More and more widely, when it is created, not iron, but PVC is used. If the project remains the same, the material count is simplified. But when it is planned to introduce a new bathroom, to divide the toilet and bathroom, to connect them or move them, it is necessary to approach the calculation of the needs for pipes and components more carefully. Be sure to have to remove the old fan tee from cast iron, because it is too long, takes up a lot of usable space and is almost always worn out.

Isolated replacement of the riser in one apartment is quite acceptable for technical parameters, even when the owners of the premises above and below categorically object. It is very important to fix with the help of brackets all parts of the sewage system longer than 1 m. When trying to clean mechanically poorly fixed or loosely installed pipes, all joints simply diverge. When the riser is installed, a pipe with a section of 5 cm is assembled, which is formed from pieces of the required length.

It so happens that the desired area is not - then just cut it out of the longer with a saw for metal.

Heating

On the street, any pipes, including heating, can be laid out by the trenchless system. But here it’s interesting not how to work for installers of utilities (they themselves will understand), but how to connect the heating circuit in the apartment itself. Regardless of whether it is planned to use joints for welding or to lay plastic communications, the best moment for this procedure is early summer, when the heating season and hydraulic tests are already over. The use of ferrous metal is recommended to leave only in the most extreme case, because it is impractical and too easy, it will quickly rust.A more perfect choice is a pipe with a zinc layer on the front surface and along the internal cross section. But it is useful to bear in mind that the installation of such structures is difficult, and it is difficult to process them to give the necessary properties. Therefore, if the choice is still stopped on metal structures, it is best to use high-quality stainless steel. It is able to bend in the chosen direction on a small radius, maintaining the original strength.

As with the vertical and horizontal wiring heating there are universal rules. It is advisable to lay pipes in parallel, excluding intersections. It is better to refuse diagonal moves. Such nuances are especially valuable when hidden installation, because they allow not to risk once again, drilling the wall or fixing something on it.

When posting pipes on the floor, on the wall and even on the ceilings, it is required to ensure that each joint and each joint has unlimited access; the controller is connected so that it affects the temperature only in the apartment, but not throughout the riser.

Connection Features

Just to know the scheme of installing plumbing or heating pipes is not enough, you also need to understand the specifics of their joints. There can be no such apartment where it would be possible to do without docking.The choice of a split or nonseparable joint is determined primarily by the type of structural material; variants to be analyzed are also divided into flange and coupling subtypes. The flange is widely used in the creation of PVC pipelines. The fastener is made of cast iron, a rubber gasket is placed inside the connecting part.

In the place where the pipes are connected, they are cut; chamfer formation is not necessary, but an ideal cut must always be created. A free flange is placed on it. The gasket is inserted inside, while ensuring that it extends 100 mm from the notch line. A flange is placed on top, which is bolted to similar structures on the other side.

Spinning the bolts, do not apply extra zeal.

Coupling technique implies that the outer ends of the joined pipes are cut at a right angle. A clutch is applied to the right place, its middle should be exactly at the junction. Having marked this position, the coupling and the end parts are processed, one pipe is inserted and the second is inserted, achieving unity of the longitudinal axis. Next, push the clutch to another pipe, also controlling the progress of work on the mark.Both schemes are equally acceptable for pipelines of any internal diameter, created on a tee or collector system.

Common mistakes

But in order to do everything correctly, it is not enough just to study the most popular materials and wiring diagrams. An experienced plumber will easily evaluate whether the pipes were correctly laid in a particular case, however, the consumer himself can determine this without waiting for undue pressure changes or failures in the water meters. When repairing, the most common mistake is to ignore the requirements for a free approach to communications. The openings should be relatively small, easily closed on the doors, so this does not create problems for the design.

The location of metering devices is often made very low due to the ill-considered following of the design concept.excessively high; Some “enthusiasts” completely close them with plumbing, furniture, or even put under a bath. For your information: all water and heat meters must be at the level of the toilet bowl or higher, since breaking this rule does not allow registering them and receiving corresponding benefits.

Do not connect plumbing fixtures until communications are completed. This, if not lead to accidents, it can worsen the result. It is necessary not to try to save as much as possible, but to be able to admit to yourself what kind of work will surely prove an unbearable burden.

Even qualified craftsmen try to buy pipes a little longer than the initial calculations follow. With self-assembly is even more relevant. It is recommended to purchase all components at one time, from a single material and under one brand.

No matter what is done - sewage, plumbing or heating: the fewer bends, turns and transitions, the better. It is necessary to carefully observe the rules for bias and diameter change.

To learn how to replace old pipes with plastic, see the following video.