Choosing plastic plugs for pipes

Quite often, it is the small details in the design that perform important functions. A similar rule applies to pipe plugs, which can be made of different materials, including plastic. It is these raw materials that have positively proven themselves during operation, and therefore are used everywhere.

Special features

Plastic communications can be found quite often. For the production of plastic plugs, an inexpensive polymer is used as a material, due to which products have a lower cost in comparison with similar products made of metal, which makes it popular. In addition to an attractive price, plastic, in contrast to alloys, is resistant to corrosion processes, retains its properties at high levels of humidity, is resistant to UV light and negative temperatures, which has a positive effect on consumer demand.

Pipe plugs are simple configuration fittings., the main function of which is to restrict the flow of water or other medium in a water supply system or pipeline for other purposes. In addition to this function, the products act as a sealing part in the construction of fences or fences made of pipes. To put it, there is no need to use a special expensive tool or to attract specialists.

The choice of plastic caps is quite diverse - the products differ in shape, size, and also in the area of destination.

Such fittings are relevant in cases where the task is to isolate a certain area of the plumbing system, but it is not planned to brew a metal product, since this transport section will be used later, for example, installation of any equipment is planned there or the trunk itself will increase in this segment of the structure .

Among the main areas of application of plugs are a few.

- Fittings are required during the installation of the audit in the sewer system.Features of the device design require the use of cork in the horizontal parts of the pipeline in order to reduce the risk of system blockages.

- The cap is in demand to restrict the water supply to some separate part of the sewage system in situations where repair or installation of certain components is planned, and some parts are not yet ready for installation. In case of emergency situations, the use of fittings will temporarily shut off the water supply, for example, when replacing a rusty section with a new segment.

- With the help of plastic plugs, lateral branches of communications are being sealed, which can still be used. Modern modular plumbing systems make it possible to perform any modernization and transformation of communications, for this it is enough to unscrew or, on the contrary, install a plastic cap.

- Products are often used as a decorative component, for example, when installing fences of core and drill pipes, sheet materials and profiles, to prevent the ingress of various debris and moisture in the cavity pillars.

- In the course of work with polypropylene pipes, plastic plugs are welded to various parts of the pipeline by welding, when the need for them disappears, the cork is simply cut off.

Kinds

Today, the choice of plugs for pipes made of polymers has greatly increased, so choosing the necessary product, taking into account individual preferences regarding the size, shape and color, is not difficult.

To classify products based on a variety of criteria.

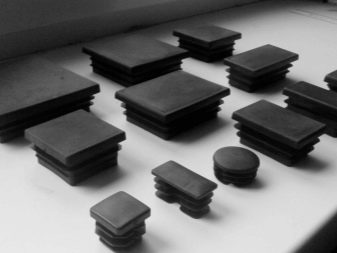

In appearance of the fitting elements are:

- square-shaped plugs;

- oval elements;

- round caps;

- spherical fittings;

- rectangular elements.

Square production is divided into the following subspecies:

- petrol resistant;

- multi-dimensional products;

- heat resistant covers;

- network;

- bypass;

- flange;

- mechanical.

Given the size of plastic parts for the pipeline, the following types can be distinguished:

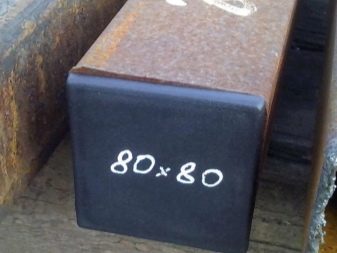

- products recommended for use in conjunction with shaped pipes - it has a square shape and the following dimensions: 1.5x1.5 cm, 2x2 cm, 2.5x2.5 cm, 3x3 cm, 4x4 cm, 5x5 cm, 6x6 cm, 8x8 cm, 10x10 cm;

- rectangular covers are presented in the following sizes: 1.5x3 cm, 2x3 cm, 2x3.5 cm, 2x4 cm, 2x6 cm, 2.5x4 cm, 2.5x5 cm, 3x5 cm, 4x6 cm, 4x8 cm;

- circular shapes are realized with the following cross section - 2.5 cm, 4 cm, 5.7 cm, 7.6 cm;

- In addition, many manufacturers offer products that will be manufactured according to individual pipe sizes that have non-standard parameters.

Taking into account the design features, plastic products are of several types.

- Threaded plugs - such products are most in demand among consumers, they are used in the process of installing water and gas communications. Steel is used for the production of such goods. In order to install such plugs, you should additionally use special materials to seal the joint, for example, fum-tape, the use of sealants is not recommended, since it will be rather difficult to unscrew the cover treated with the compound if necessary.

- Flange elements - such plugs are implemented for pipes with a diameter of more than 2 ?. Such covers are fixed with a bolt, rubber products are used as gaskets.

- Spherical covers are necessary for communications that have specific operational properties, such as an oil pipeline or a gas pipeline.The manufacture of such products is subject to the relevant GOST. A feature of the products is the ability to withstand pressure up to 100 atm.

- Pneumatic covers need to work with the pipeline in an emergency. The raw material for their manufacture is rubber. The cap has a special cavity for air, it is installed in the hole made in the system, which is filled with air, thus forming a reliable overlap of the damaged area.

Based on the method of installation, plastic plugs are divided into two groups.

- Internal fittings - mounting of such elements is carried out thanks to the ribbed notches. They are installed in the socket, and the top closed with a hat.

- External plugs - they act as a decorative component, in addition, protect the inside of the pipe from moisture and blockages. The variety of forms increases the demand for similar products to be used as a decorative part in the design.

It is also worth highlighting the following types of products:

- shipping covers - they provide protection to pipes from deformation and damage during transportation;

- butt-end - protect the system from debris or else isolate a part of communications that does not function;

- Fittings for double-wall pipes - similar products are intended for straight, flexible drainage corrugated pipes, used during transportation or storage of products.

Plastic fittings are widely used for domestic needs, as well as for industrial purposes, the installation of products is not particularly difficult, however, they do an excellent job with the tasks.

How to drown out?

The pipeline can operate according to a different principle, there are systems that transport media under pressure, in which case they are called pressurized, as well as communications that operate without additional influence, such systems are called pressureless. Based on these features, the method of fixing plastic products in the communication network differs.

In the designs of the latter type of product are used to seal the joints.

Technology implementation of the installation of the following:

- in the socket place the sealing ring;

- the cover treated with soapy composition is pressed inwards;

- measure the depth of the ring with a special plate.

Installation of plugs in pressure networks - the task is more time consuming. In such work, not only the tightness of the joint is important, but also its strength. That is why the fastening of fittings in such networks occurs when using welding equipment, resistant adhesives, or using a threaded connection. The last option assumes that by the end of the pipe it will be possible to add some more number of pipes when removing the threaded plug. Welding and glue exclude such a possibility, as a result of their use a permanent connection is formed.

There are several options for performing one-piece mounting plugs.

- Installations using diffusion welding. In the course of performing such work, a special heating device is used, which melts the outer parts of the pipe and plugs. After this treatment, the system element is pressed into the fitting.

- Fastening with glue - in this case, the application of the tool to the outer area of the pipe and the inside of the product is performed.After that, put the lid on the pipe and carefully turn it to evenly distribute the composition. After a few minutes at the junction of the elements formed a strong connection. This option is preferred to be used most often, because for the performance of work does not require the acquisition and use of specialized equipment.

In addition, the installation of plugs is sometimes performed on a pressed or crimp fitting, in this case a compression sleeve with a fitting is used as a plug, which is placed in the pipe. It is crimped using a mounting nut. This option is a kind of detachable connection, which, if necessary, can be quickly disassembled.

Tips

Purchase of such products does not require mandatory consultation of specialists, it will be enough to examine the product range of this line and adhere to the recommendations of experts regarding the characteristics of the product.

- Based on the application of the product can vary significantly - stubs may have a different level of reliability. So, if there is a question about purchasing products for temporary use,You can opt for shaped products that you can install yourself without using additional equipment or special tools. When it comes to installing plastic caps for a long time, you should purchase fittings that are fastened by welding.

- Products should be made of the same material as the pipe - for PVC highways, you should choose products made of polyvinyl chloride; for PND-pipes, the cover should be made of low-pressure polyethylene. When it is intended to use the covers as a decorative element, you can buy plastic products. This raw material is quite soft and flexible, besides, the products are presented in a large color variety.

- The cross-section of products plays an important role in the selection of plastic plugs - for works on sealing sewage and water supply networks, round plugs are used, their diameter should be the same as that of the pipe. This parameter is very important, since even minimal differences of a few millimeters up or down between the cross-section of the lid and the tube will not allow the elements to be operated together.

Given the above characteristics of products, you can easily cope with the task of acquiring such products.

How to choose plastic plugs for pipes, see the following video.