Choosing a machine for cutting and pipe trimming

When the question arises of buying a special device for cutting and trimming pipes, many masters think that such a product should be as useful and durable as possible. In addition, it should be convenient to use, which is difficult for an ordinary buyer to determine without knowing the variety of units and the rules for their use.

Special features

Metal pipes are made from different raw materials:

- cast iron;

- carbon and stainless steel;

- brass;

- aluminum and other composite materials.

They are cut by a mechanized or automated method on different equipment. The use of a machine for cutting and trimming pipes allows for more accurate, fast and high-quality cutting of pipes in comparison with manual cutting.

All existing types of such devices can be divided into two types: gas-flame and non-flame (mechanical).

A distinctive feature of the products of the first group is versatility. They are comfortable and characterized by low weight. This allows them to operate in different conditions, in addition to the shop, during installation and repair of the pipeline. It is simple to install them on pipes to one worker.

In addition, they provide for easy reconfiguration of the pipe diameter. In essence, these are mobile or portable units, which, depending on the type of cutter, can be:

- gas-oxygen;

- plasma;

- jets.

Models may have auxiliary rotating devices that simplify pipe cutting. Analogs of mechanical cutting are needed for cutting and obtaining the perfect chamfer, which is characteristic of new factory pipes. These devices do not generate sparks when used, so they are used in work with oil and gas pipelines, in which open flame is unacceptable. They are equipped with a mechanized trolley, so that you can move around the pipe at the expense of the chain.

Kinds

Machines for cutting pipes are different - it depends on the destination. These include portable or stationary units with different technical nuances. The first are suitable for small amounts of work. They are needed for dissecting pipes and processing their edges. In contrast, stationary devices carry out cutting of non-standard pipes with simultaneous processing of the edge of the pipe for subsequent joining.

Based on the characteristics of the pipe material, the choice of machine may be different, as shown in the table below.

Selection by type of material

Devices | Pipe material |

fireless | polymer flammable pipeline |

roller | copper, brass |

gas cutting | steel, cast iron, from ferrous metals |

guillotine | composite, multicomponent |

orbital | from plastic, iron, cast iron, steel |

band sawing machines | cast iron, copper and alloys of steel, cast iron, iron |

grinding | composite, multicomponent |

- Fascicants may be normal or stationary. When buying the first option you need to rely on the thickness of the pipes and the material of their manufacture, otherwise such a machine may not be suitable.

- Disk drives cutting devices acquire for cutting pipes of steel, iron and iron with a diameter of 110-152 mm.Their cutting is fast and does not require additional processing of the edges of the pipeline.

- Orbital analogues are remarkable in that they are equally convenient in working with pipes made of plastic and thick-walled stainless material. They are quite effective in working with pipes of different types (sewer, water, gas). They have cutters for cutting with simultaneous chamfering.

- Band sawing machine The models are convenient because they do not depend on the wall thickness of the pipes. At the same time the speed of a cut is selected individually for each material. Such products can be portable, two-post, cantilever or gravitational.

- Gas cutting machines operate on the basis of the gas-oxygen mixture. They are characterized by an impeccable cut of a pipe made of different materials, and provide for operation in various planes. In addition, they allow work on a pattern that allows you to get identical parts of pipes in several copies.

Products can be manual and automatic, with detachable and one-piece pipe cutters.

Instruments

Today on the market for such products can be found different portable equipment for cutting and processing pipes.To choose the device correctly, you need to consider the design features, whether it is a flameless cutting and trimming machine or a disk knife.

The best type of devices for trimming metal and plastic pipes and chamfering are cold or non-fire method machines. In addition to the cutter function, they provide for chamfering from the inner and outer sides of the pipe walls, as well as boring the inner diameter.

In fact, some devices are designed for industrial use, other options are suitable for field conditions. For example, tools for cutting and trimming pipes in industrial environments are four varieties.

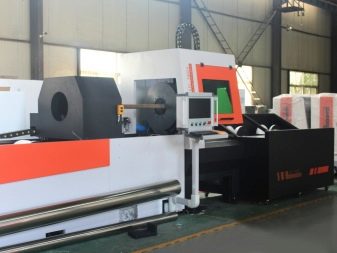

- Laser. Such a device has a power in the range of 200-1000 watts. Cutting with a laser machine is characterized by a minimum cut width, the possibility of cutting a thin-walled pipeline from brittle materials. At the same time, the pipes practically do not undergo thermal deformation, since they do not heat up. The device works at the expense of a fiber, solid-state or carbon dioxide laser. If necessary, the device can be used in work with pipes whose wall thickness is 4-5 cm.It is an excellent tool for laser cutting pipes with low thermal conductivity.

- Plasma. In such devices, the function of the torch is replaced by a jet of ionized gas, the temperature of which reaches 30 thousand degrees at a speed of 1.5 km / s. Its heating is provided by an electric arc. Just like the previous analogue, the unit needs intensive cooling. The working tool of the device is a gas that reacts with the metal. The machine has a high cutting speed, instantaneous evaporation of the metal in contact with the plasma and the complexity of the shape of the cut.

- Hydroabrasive technique. This device is used when high demands are placed on the quality of the cut. Instead of an abrasive wheel, garnet sand is used here. Such a product is able to cope with the cutting of all known materials, including titanium and tungsten, as well as super-heavy alloys. The wall thickness of the pipe can be up to 30 cm. Regardless of the type of pipeline, it will not heat up in the cut area. The speed of work is significantly higher than the first two analogues.

- Saw. This device is simpler than other machines and is a typical disk machine.The function of cutting is performed by a saw with fine teeth, made of hard alloys. In the market for such devices you can buy automatic or semi-automatic. Depending on the variety, they can be equipped with special trays for loading the blanks or providing for integration with other machines (for example, chamfering or rolling machines). More often, such products are purchased for cutting thick-walled steel pipes. On the market you can buy saber products on batteries.

- Field and household. When laying water pipelines, as well as gas mains and similar systems, gas is used. In most cases, these are propane cutters with a saddle or a collar encircling the pipe, as well as a flexible steel band, chain, magnetic suspension. The disadvantage of most models is the fact that it is impossible to achieve a complex shape, as well as working at an angle. However, they can be used in a wide variety of conditions, even under water, although the cutting line will not be as flat as when using gas cutting machines.

In addition, use a mill. The disadvantage of this machine is more noise during operation in comparison with the propane analogue.In home workshops, pipe cutters and electric welding are usually used for cutting.

How to use?

The use of the machine depends on its type. For example, to cut a thick-walled tube with a diameter of 170 mm, you can use a circular saw for metal. To do this, the pipe is fixed on the machine, attracting, so that in the process of cutting it does not jump off the device. Belt tension should be tight and reliable. Eliminated reel pipe to the side.

It is necessary to apply the markup or trim level. To do this, use a special device with a limiter and a fatty pencil, which is practically not erased. Then the circular knife is turned in the direction of the pipe and check the coincidence of the cutting line with the marking. The device is connected to the network and begin the process of sawing, gradually lowering the disc with the protective housing down.

Then also lift it smoothly. With a large diameter of the pipe, it is slightly loosened and turned, observing the exact hit of the disc knife. Then the pipe is again attracted to the machine and perform a cut until the pipe cuts through. After that, the disk assembly is turned off and the state of the slice is evaluated.

Usually when working with Japanese saws, the masters note that there is no burrs on the cut. At the same time, the metal practically does not heat up.

When using a machine for facing, they lean against the pipe and drive around, clearing the cut and aligning it under the fittings. The facet is removed at an angle of 60 degrees for smooth adjustment of the angle. The width of the chamfer can be up to 10 mm. This indicator depends on the diameter of the pipes used.

Tips

To choose the right machine for cutting and trimming, you need to take into account several useful recommendations.

- Professional masters who, because of their work, know the subtleties of each device, will help determine the model.

- You can view information on the forums dedicated to this topic.

- It is important to consider the type of pipe. If the product is not adapted for them, it is unlikely to be durable, and simply will not work.

- It is necessary to know the minimum and maximum diameter. Knowledge of the range will allow you to understand how the profile unit works with which diameter. Ideally, it should cut through thick-walled pipes, although the material also matters. It will show what type of raw material the device cannot handle.For this reason, many craftsmen prefer automatic steel machines.

- When buying, you need to consider that a good product is not cheap - it is not sold on sale with an attractive discount. This should alert the buyer. You need to buy the product from a trusted manufacturer that is highly appreciated by professionals in the field of working with pipes. You can ask the seller for a certificate of quality and related documentation that will indicate a good product.

With regards to the stationary or portable model, the buyer decides on his own - there is no rigid framework. Well, if the device involves working with patterns or stamp, cut at an angle.

- You can pay attention to the profile machine with a clear fixation, if it means cutting large diameter pipes. According to experts, such devices often eliminate the need to clean the cut manually using various tools. These units include models for welding. Connection by threaded methods involves the use of special devices for threading.

Review the machine for processing the end of the pipe, see the video below.