Pipe in a ditch under the arrival on the site: how to choose and lay correctly?

In the process of arranging the site can not be small things. For example, a good owner will always take care of the drainage pipe when entering the site. It is important to ensure the elimination of precipitation from the road, to prevent waterlogging and to arrange unhindered entry into the territory of a private site. However, the choice of such drainage has its own nuances, as well as its proper installation.

Design

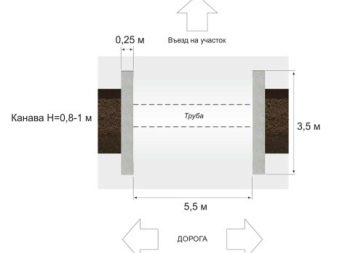

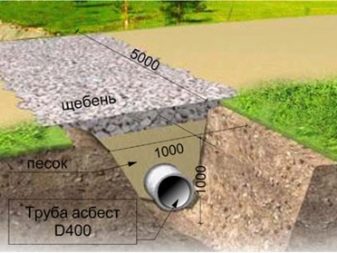

Ditch under the race to the site should take into account the width of the passage. On average, this figure is 4 m or more. It is necessary to immediately design a variant in which the entry will be calculated on a truck. It is important that each side has at least 1 m of protection zone. So the pipe will not be subject to great operating pressure.

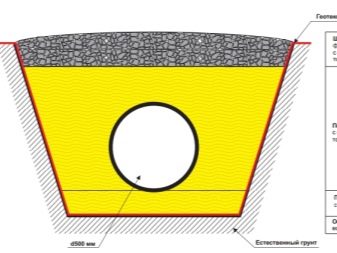

For this reason, on average, the width of the section is projected within 6 m. This is convenient due to the fact that it coincides with the factory length of the pipes. It is important to design the correct ditch profile for entry and flow of water. The main thing is that the width of the passage is stable without narrowing and bending. At the site of transport, the ditch should have the form of an inverted trapezoid. In this case, the bottom should be flat.

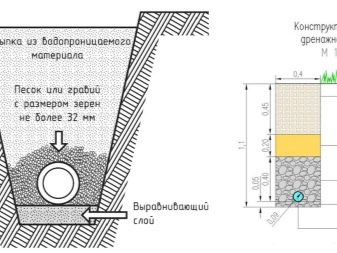

The optimal width parameters vary in the range of 40-100 cm. This indicator depends on the diameter of the laid pipe (the larger it is, the greater the width of the ditch). The project takes into account the elimination of pipe suction into the ground. For this, the bottom is made in the form of a rectangular pit with a depth of about 25 cm. A pit will allow you to create incompressibility of bedding.

In addition, the design should take into account the regular cropping channel. Accumulating soil is used for adjacent areas. When the difference between the parties in the 20-30 cm to align the ditch try to apply freshly dug earth. When the difference is greater, quartz crushed stone about 10 mm thick is included in the drainage device. The excess soil is removed for storage or for use in landscape design.

Drainage device

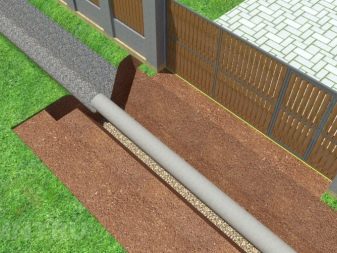

First of all the ditch is necessary for removal of precipitation. However, the ditch should not become a problem to enter the car to the country. The drainage device will be a pipe placed in a ditch. At the same time the construction will be covered with soil, differing not only in functionality, but also in aesthetic appeal. The ditch should run along the main road.

With the seeming complexity, such drainage can be performed without the involvement of specialists from the outside. It is only important to choose the type of material, pipe size, prepare crushed stone, sand and earth. In addition, it is necessary to take into account the resistance of the pipe to corrosion, as well as to prepare tools (shovel and wrapping material). The drainage device will be a closed system from a trench with a flooring and a layer of soil, pipe.

Any of the protective zones of the drainage system, whether right or left, must have an extension. For this purpose, so-called notches 50 cm are made in the trench. Usually they are excavated along the edges of the trench to the highest point. Regardless of road pit falling asleep, it is necessary to maintain constant depth.For this reason, the notches are also filled with the same rubble. On average, the depth should be 60 cm.

Buying a pipe is a top priority. It is necessary to take into account the weight load that it can withstand. The flow channel will be located transversely to the vehicle. The pipe should not rise above the entrance. Usually in the device they try to use the material, correctly selecting its diameter. In case of using a metal pipe, it must be painted outside or smeared with bitumen mastic.

When using a material with a small cross-section, the edges are closed with a welded grille, the cell size of which does not exceed 1.5 cm. This drainage element will protect the pipe from clogging. With a large pipe diameter clogging is unlikely. For example, if the section is 50-60 cm, the pipe is placed in the group of service systems. Such pipes need to be equipped with a lock-quarter.

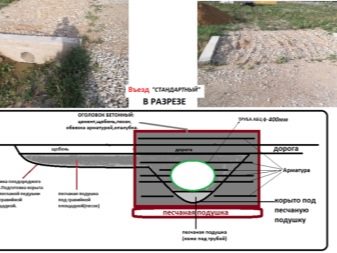

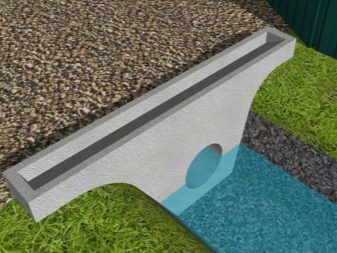

Trays can be installed upside down, as they do when laying the heating main. Sometimes corrugated pipes with stiffeners are included in the drainage device. The design depends on the trench profile and the width of the channel.At the same time, the width of the inverted trapezoid bottom should be 30–40 cm larger than the diameter of the pipe itself. An important nuance in the system is the fact that the flow tube during installation should be placed horizontally. Sometimes a concrete bridge is poured over the ditch, which distributes the load.

Performance materials

For laying the pipe into the ditch under the entrance to the suburban area today use different materials. Each type has its own characteristics, the ability to withstand weight loads and a lifetime. The main factor in the choice of products for drainage in this case is the fact that the pipe must have maximum rigidity and carrying capacity. To date, several varieties are selected for drainage.

Metallic

More often for these systems use pipes from steel. They are characterized by strength and durability, although they are not sufficiently resistant to corrosion. On average, they can serve as a drainage system before entering within 30-40 years. In addition to the large diameter, such products have thick walls and are distinguished by their ability to withstand substantial weight loads. Even with the repeated passage of heavy machinery, they will not bend or deform. Therefore, the drain will not be broken.

Concrete

This option is popular, despite the difficulty of bringing the pipe itself, as well as its installation. Concrete pipe allows you to provide a significant passage of water, and it does not destroy the pavement itself. These pipes are distinguished by their high weight and considerable wall thickness. They weigh a lot, so that their installation is often impossible in the domestic environment or requires special lifts. The disadvantage of this material is its instability to destruction over time.

Reinforced concrete

These are pipes made of steel frame, filled with concrete, compacted by centrifuges and vibropressing. They have 2 categories with different bearing capacity (up to 6 and 10 m).

When installing reinforced concrete products, it is necessary to additionally create a “pillow” of sand. This is necessary in order to reduce the risk of pipe breakage under heavy weight. Installation of a ditch with such a pipe is time consuming, and from above it will have to be protected from weight loads.

Plastic

Such pipes are corrugated, differ in the small weight, the budgetary cost.They are reliable, inert to rust and deformation. Their throughput and ring stiffness are quite high. Such pipes are characterized by safety, they are easy to install the drainage ditch. Their installation does not require an order of special lifting equipment, moreover, such pipes do not collapse with time.

Options

The best design of the ditch is a drainage. This option is convenient because it is diverse in the choice of sizes and features. In contrast to the seepage of water through the material of the mound, the erosion of the roadway is not excluded, which may cause an emergency situation. The design of arrival should provide drain only through the drain pipe. Depending on the type of material, it is simply filled with soil or poured with concrete.

Practice shows that bridges made by pouring are more durable than variants with soil tamping. It is noted that subsequent pouring increases the service life of pipes. Subject to the rules of laying the pipe, it may last longer than the stated period. Plastic drainage pipes with geotextiles are characterized by perforation.Due to the filter, they absorb moisture coming from the soil. These products are made of double-layer polypropylene.

Criterias of choice

What material to give preference, everyone decides for himself. Usually, the determining factor is not so much the material as the definition of the section. It should be sufficient for the smooth passage of groundwater and rainwater, even with abundant quantities. It is important to consider measures to prevent clogging of the pipe itself (especially if the width of the passage is large). Since water carries with it garbage and dirt, besides pipes it is necessary to take care of the gratings. To do this, you can choose steel products.

Given that the concrete is destroyed, and reinforced concrete is laborious to install, it is easier to arrange the embankment with the help of a plastic corrugated pipe. It is this material that should be chosen by the novice and those who are planning to use special lifting equipment. Its convenience is the fact that such a pipe can be cut on its own without special stationary machines. However, plastic will need geotextiles, which will serve as a kind of filter, not missing debris and dirt.

If there are no restrictions in the budget, and the choice is principled, they prefer steel pipes.

If you want to buy a plastic pipe, take into account the number of layers and the obligatory presence of corrugation. They may be 1-2. In this case, the second layer is corrugated. It is impossible to take a pipe created from recycled materials for a ditch. It has reduced strength and durability. Smooth plastic pipes are not suitable for laying. When choosing a pipe for drain it is worth considering 3 rules:

- budget;

- mechanical strength;

- dimensions of the ditch.

For example, when choosing a corrugated plastic product, you can press on a stiffener: if it does not return to its original shape, the product is not suitable for arranging a ditch. Plastic is better than other materials, as it does not trap debris entering the pipe along with groundwater or rainwater. However, such a system should be hidden from UV rays, which can damage plastic.

Reinforced concrete is monolithic, today such pipes are the generally accepted standard, therefore they are in high demand. If you want to buy such a pipe, you should give preference to a product with a waterproof class W6 and a low degree of water absorption (not more than 6% of the total weight). The minimum class of frost resistance should not be below the mark F200.

Metal products are not suitable for laying where the climate of the region is constantly humid, and soils are prone to waterlogging. In damp conditions, the pipe will corrode.

Laying technology

Lay the pipe into the ditch under the arrival at the cottage is easy. Compliance with the basic steps of the construction of the drainage system will allow you to properly design the structure with a trench. The technology of laying the pipe in the ground consists of several simple steps.

- Dig a trench about 1 m deep with walls and a slope.

- The ground at the bottom of the channel is rammed.

- Make a "pillow" of quartz sand.

- A layer of rubble is poured on top, using preferably crushed stone with medium granite granite.

- Layer a geotextile layer.

- Install the formwork for the concrete frame.

- Pour the concrete and lay a layer of the upper fabric or asphalt pavement.

If you do not plan to fill, dig a trench. The walls of the ditch align, the slopes perform under the slope. Sand it over the bottom with a layer of about 10 cm. Then the material is lined to the bottom, and a layer of rubble is poured onto it. After stack pipe.It is important to take into account the nuance: when laying a corrugated product with geotextiles, the pipe must not be moved in order not to damage the material.

After the pipe has been placed in the canal, it is ensured that it is led to the sewage system or to a nearby ditch. Then rubble is covered with a layer up to 30 cm, the material is wrapped. It will remain to fill the structure with sand and soil, followed by compaction and closing with turf. A layer of sand at the bottom of the trench will be at the same time leveling.

How to save the mound from erosion?

To prevent the embankment from crumbling, its edges can be reinforced with natural stone, white brick or reinforced concrete slab. The formwork is performed in such a way that the edge of the channel protrudes by approximately 10 cm behind it. To facilitate the workflow, the bottom of the channel can be covered with a mixture of ASG. It will not only level the surface, but also close the pipe. After that, engaged in the sides.

It is good if they will rise 15-20 cm above the edges of the ditch. After their arrangement, the inside is filled with rubble. After perform laying curbstones, formwork stuffed with bead.

For information on how to lay the plastic pipe in the ditch, see the next video.