How to choose a pipe of the correct diameter?

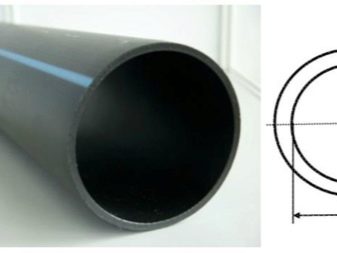

Diameter is an important characteristic of any round object. The pipe diameter is large. From it are made basic calculations for a particular project. Usually, pipe diameters are standard, however, even professionals often have a question: how to choose a pipe of the correct diameter?

Special features

Experts conditionally subdivide pipes into:

- large diameter (508 mm and more);

- average diameter (from 114 mm to 530 mm);

- small diameter (less than 114 mm).

Product features are many. For example, for a water supply, pipes of small or medium diameter are usually chosen. For other highways need larger diameter products. The choice should be determined by the technical characteristics and properties of products, as well as the conditions in which it is planned to lay the highway.

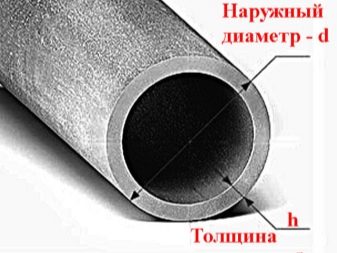

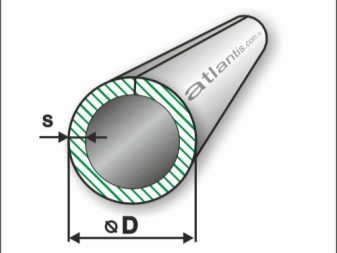

Pipe diameters are usually labeled.In addition to diameters, this parameter often takes into account the thickness of the walls of products. Marking is governed by clear parameters and specifications. There are certain state standards.

These standards are different, as there are regulations for cylindrical products, as well as for products, which are called core lines. Special molding of products makes manufacturers take into account the width and height, not the diameter.

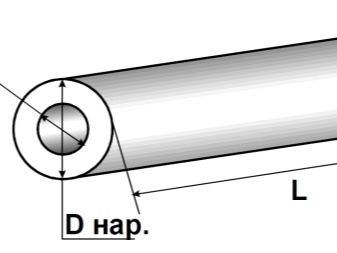

Product labeling allows you to select the line with the desired diameter. Usually, the outer size is taken for the desired size. The internal size of the pipe determines its throughput feature. Specialists of engineering profile, engaged in the creation of complex communications, find this parameter by a special formula. In marking this size is not considered.

Practical diameters of polypropylene and plastic options are indicated in GOST. The same standards exist for steel products. The question of choosing the right diameter often arises when replacing old steel products with modern polypropylene ones. In this case, the dimensions of products from plastic and metal must comply.The dimension of highways varies over a wide range. Difficulties arise from the difference in thickness of the material. For heating or sewage, it is important to consider not only the external dimension, but also a set of other indicators.

For example, for heating communications of a private house, parameters such as the height of heated buildings, the temperature difference, and the speed of the carrier that will pass through the pipes are needed.

When you buy materials yourself, you need to consider that metal pipes are usually with a lower capacity than polypropylene pipes. Yet these products are reinforced or lightweight.

GOSTs of metal or propylene pipes are different. Therefore, there are difficulties in the selection of a similar product. To facilitate the task of choice, professionals apply a special table. The data from it, though conditional, but helps to cope with the difficulties that may arise when purchasing highways.

Outer dimension of polymer pipes mm | ||

PP pipes | BSh1, ES2 | VGP3 |

16 | 17 | |

20 | 21,3 | |

25 | 26 | 26,8 |

32 | 33,5 | |

40 | 42 | 42,3 |

50 | 45 | 48 |

63 | 57 | 60 |

75 | 76 | 75,5 |

90 | 89 | 88,5 |

101,3 | ||

110 | 108 | 114 |

125 | 133 | 140 |

160 | 159 | 165 |

180 | ||

225 | 219 | |

250 | 245 | |

280 | 273 | |

315 | 325 | |

400 | 426 |

Norms

For example, GOST 18599-2001 regulates the diameters of products made of polyethylene. The dimension of metal-plastic sheet pipes is determined by GOST R53630-2009.Dimensions that are not found in guests, pipes may be. These products are usually produced for individual cases. Products, the dimension of which is not governed by GOST, are combined, made to order.

GOST Standards for pipe rolling are divided according to the method of manufacture. For example, the sizes of seamless steel pipes are regulated by GOST 8732-78, 8734-75, 10796-76, 20295-85. Standard diameter is up to 820 mm; for products made to order, it can vary up to 1420 mm.

The welded pipe complies with State Standards 3262-75, 10705, 10707, 3262, 8639, 8645, 8642. In the production of products, strip or sheet steel is usually used, which undergoes the stage of preliminary molding. The demand for this type of pipe is big enough.

Pipes can be not only round, but also square or rectangular. GOST of profile products 13663-86, their diameter varies from 478 to 1420 mm. Cast pipes are governed by GOST 10706-76. They are from 50 to 1000 mm in diameter. Such products are molded by special pipe-making machines.

In the list of GOSTs of steel highways about 40 items. Technical conditions allow the use of options in various types of pipelines.

Kinds

Pipe marking also makes it easier to choose the right option. Understanding the notation is easy.

The main classification includes only four types of products.

- The first is the standard designation of PPH. Products marked with this are considered high strength. Scope of products - cold water.

- The second type is sold under the marking PPR. These polymeric products are suitable for both cold water and underfloor heating.

- The third type is indicated by PP and is widely used due to the volumetric sphere of use. Products are suitable for any engineering systems.

- Another type with a wide scope of use is marked PPP. These pipes are different in color, for which purpose you will use these or other products, it does not matter. The only black propylene products are usually maximally protected from exposure to ultraviolet radiation.

By the way, the combination of PP or HDPE in Russian or English transcription always indicates that the options are polypropylene. The remaining letters used for marking indicate additives that are part of classical polypropylene. Marking may also indicate the manufacturer of the product.Other products sometimes include quality marks. Sometimes the product contains signs that indicate the technology used.

If the diameter of the products for the engineering system is chosen incorrectly - for example, it is more than the standard values, then the heating devices will not provide the necessary heat. Smaller pipes will be ineffective, and they will also create excessive noise emanating from plumbing fixtures.

Types of PP are still fluoroplastic. These products did not receive such distribution in private arrangement of engineering systems, as polypropylene products. However, they are widely used in industry. Stainless and asbestos cement are rarely used for internal engineering systems. However, construction of drilling wells and external water pipelines does not do without them. "Stainless steel" as well as polypropylene products have regulatory compliance.

The main classification includes several varieties:

- suture or seamless;

- cold rolled or hot rolled;

- round or profile;

- thick or thin.

Pipe rolling is distinguished by such advantages as durability, possibility of operation under high pressure, resistance to drops, plasticity, resistance to aggressive media.

Pig-iron pipes, like all other types, differ in types:

- VCHSH - pressure head;

- Cheka - free;

- SML - without socket;

- ChNR - with a bell.

The main disadvantage of all cast iron products is fragility. However, at the same time, they have high fire resistance, rigidity, resistance to temperature differences.

In addition to stainless steel, cast iron or polypropylene pipes, there are also such variants of pipe foundations:

- aluminum;

- copper;

- titanium.

These foundations are more commonly used in various industrial fields. High rigidity, resistance to loads are peculiar to highways. The main drawback of highways is the high price.

Dimensions

The comparison table above simplifies the selection if the size is indicated in millimeters. The standard size of products is sometimes in inches, centimeters and other measurement values. The classification of dimensions by diameter is extensive. The values are related to the capabilities of the designed system, as well as the characteristics of the transported media.

Dimensions of outer diameter are usually denoted by DN and it is measured in mm. In the same value, the permeability of the system as a whole is measured.This physical characteristic of the diameter is taken into account, even if the pipe is rectangular. The standard designation is conditional, for round iron or polypropylene pipes measured in inches.

Inch values are usually rounded. In inches measured tubes of steel. This is a common dimension that defines the dimensions of the products. Polymer tubes are measured in millimeters. To choose the right elements, you need to know the fundamental difference between the values. Special tables help in the selection.

Pipe Gauge | Thread | External dimension of steel pipe rolling | The outer diameter of the polymer pipe |

10 | 3/8 | 17 | 16 |

15 | 1/2 | 21,3 | 20 |

20 | 3/4 | 26,8 | 25 |

25 | 1 | 33,5 | 32 |

32 | 1 1/4 | 42.3 | 40 |

40 | 1 1/2 | 48 | 50 |

50 | 2 | 60 | 63 |

65 | 2 1/2 | 75,5 | 75 |

80 | 3 | 88,5 | 90 |

90 | 3 1/2 | 101,3 | 110 |

100 | 4 | 114 | 125 |

125 | 5 | 140 | 140 |

150 | 6 | 165 | 160 |

This table conveniently presents the ratio of the diameter of steel products, measured in inches, as well as polymer products, measured in mm. If it is necessary to convert the metric measurement to inches, the resulting value is rounded up.

Another standard characteristic of a circular line, expressed in millimeters, is displayed in the bandwidth capabilities of the system. In the classification of steel pipe-rolling, this figure is determined by calculating the difference between the internal and external dimensions of the products.

Similar comparative tables are available for pipes made of copper, brass or plastic rolled. Comparison chart sizes help connect elements from different materials using suitable fittings. Different nuances of connecting elements are better taken into account in advance.

How to choose?

It is difficult to determine which pipes are the best for a particular engineering system. There are various modifications from identical bases. It is even more difficult for a non-professional to create all communications systems quality indicators.

Comparison will help analysis in which it is important to include all the characteristics of products. For example, HDPE pipes are not very good quality. Polyethylene has the lowest quality characteristics. The use of pipes for transporting hot liquids is generally impossible.

Polypropylene has an average quality score. The price category of these pipes is higher than that of polyethylene products.

The average quality score for copper pipes. However, the cost of these products is even higher, so they are rarely considered for the creation of private engineering systems.

Metal pipes have even better quality compared to previous versions. However, the use of these products is impractical in an apartment building.They are distinguished by the unreliability of mechanical connections.

The quality level of steel pipes is higher than the previous ones. However, the price category of products makes them not very popular. The highest quality in stainless steel pipes. The price of products is also one of the highest in the ranking. These products are irreplaceable in conditions when it is necessary to transport pure liquids in the conditions of influence of UV rays.

The best universal option for the creation of utilities for various purposes are polypropylene pipes. The only drawback of these products is possible stratification during long-term operation in inappropriate conditions. For example, such highways are not a very suitable option for risers, since straightness can be changed in systems.

Because of this, there is a likelihood of a decrease in pressure, the quality of the system as a whole also decreases. Due to the curvature, there is a need to increase the space occupied by pipes, which is impossible when creating systems for air conditioners. However, polypropylene products are still very popular in comparison with other types.

Tips

Dimension - not the only nuance, according to which you need to choose products. Reliability, strength and durability of the material is unimportant, except for a samovar pipe.

In other cases, except for the above conditions, it is important to take into account also:

- the cost of purchasing materials, components;

- the complexity of the assembly system.

In addition to studying the characteristics of highways, information about the existing engineering system is also important. Equally important is the location of the building. All modern nodes must comply with the requirements of GOST. Only such products are allowed to mount in household communications. Do not save on components or fittings of underground production. The use of poor-quality goods in complex engineering systems can lead to great trouble.

Approach meticulously to the choice of not only pipes, but also connectors. More importantly choose equipment carefully. After all, welding and tapping should be done with high-quality equipment, and to use it you need to have the appropriate skills. If there are none, consider the need to involve professionals or choose products whose connection does not require the use of special equipment.

Metalplastic pipes possess such advantage. However, the connectors will have to be periodically checked for tightness. Therefore, it is important to keep the joints accessible for further maintenance. Do not rely on aesthetics when using metal-plastic products.

In general, the replacement of any engineering communications is a work that seems seemingly simple at first glance. Just knowing the quality of pipe assembly is unlikely to help. Take into account all the nuances in accordance with the operating conditions of the system. If there is uncertainty in your own knowledge, it is better to choose one of the organizations that offer services in this area. Thus, you will receive guarantees for the work performed and will be able to demand compensation in case of unforeseen circumstances.

How to choose the right pipe diameter, see the video below.