Double-walled corrugated pipes: scope and installation technology

The construction of many modern residential and industrial facilities is accompanied by underground installation of engineering structures. For example, various cables, water and sewer networks are being laid. In such cases, it is impossible to do without corrugated pipes that cover and reliably protect underground utilities from moisture and damage. High demand and excellent characteristics of such pipes have led to the emergence of a new, even better variety - double-walled corrugated pipe.

Device and purpose

Corrugated double-wall pipe is made of HDPE and LDPE (low and high pressure polyethylene), polypropylene and PVC (polyvinyl chloride). Depending on the application, the manufacturer uses a certain polymeric material and produces pipes according to a special current GOST.For example, double-layer PVC electrical pipe is manufactured in factories according to GOST 32126.1-2013.

The most common are protective products made of low and high pressure polyethylene. The combination of these polymers provides the best quality product.

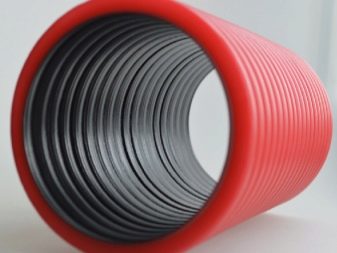

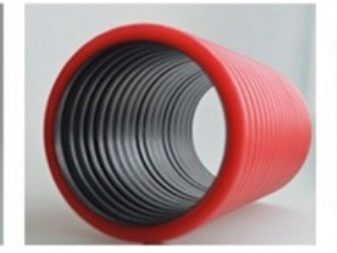

Such hoses from the inside have a layer of high-pressure polyethylene, which provides special strength to the ribs. In addition, PVD has a smooth surface without chipping, which ensures easy installation and fixing of low and high voltage cables in the cavity of the pipe. The outer layer of double-wall corrugated products is usually not made of LDPE, but of low-pressure polyethylene. The solid structure of polyethylene of low pressure provides rigidity and reliability of external corrugated surfaces of pipes. Thus, the outer coating of double-walled tubes plays a protective role from mechanical stress, and also eliminates cable rupture.

On the one hand, the outer surface of pipes of various colors simplifies laying in the ground, and on the other hand, it makes it easy to determine the scope of application. So, in red corrugated pipes, which exclude the possibility of electric shock, high-voltage electrical networks are laid.Pipes of blue color are used for installation of modern telecommunication networks and other communication lines. Black is used when laying corporate, regional and global networks of general purpose.

Given the overall structure and the above strength characteristics, it can be concluded that the purpose of such double-wall products. For many years, such products have been used for electric communication networks in the communal, transport and private sector. In the first case - for the placement of power supply networks, even near groundwater. In the second, as a coating for lighting networks, and in the third case, as a security for cables along railways and highways.

In the private sector, they are usually used for removal of sewage and drainage, although the use of such pipes here is limited only by the imagination of the buyer.

Advantages and disadvantages

Like other types, double-layer pipes have a number of certain advantages, and, of course, disadvantages. First of all, they depend on the material from which the product is made, the method of manufacture, the area of possible application and the characteristics of pipes made from other materials. The advantages of the considered corrugated products include the following:

- reliability of the design and resistance to bending, mechanical deformations from the outside and other force effects. This advantage is due to the flexible and at the same time durable structure of the polymer hose;

- resistance to the action of not only moisture, but also other chemically inactive and active liquids and dirt, thanks to which they are used as protection for cables from water or to drain storm drains;

- resistance to seismic vibrations of HDPE pipes is much higher than that of metal and asbestos-cement products having the same dimensions;

- ease compared to the above materials;

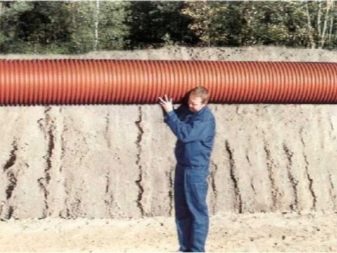

- ease of installation of products from low and high pressure polyethylene, which allows the use of a minimum number of people for laying work and not resorting to the use of particularly complex equipment;

- due to the special corrugated structure, the flexible pipe facilitates the laying of non-standard shapes and reduces the amount of used products;

- long service life ensures excellent performance for more than fifty years.

In addition to these advantages, double-walled corrugated products also have certain disadvantages.

- Low temperature range of application. For example, PVC pipes (polyvinyl chloride) work up to +45 degrees Celsius. If this mode is not performed, the design at high temperatures can deform and damage the cable due to the softening of the material. On the other hand, if we exclude the heating of the above norm, then such a pipe will be fine, and most importantly, it will take a long time to cope with the tasks assigned to it.

- Sun exposureand, as a consequence, excessive heating also negatively affects these polymeric products. It is especially scary for double-layer pipes, the upper layer of which is made of polyvinyl chloride. However, since they are most often used for underground work, this significantly reduces the exposure to sunlight.

- Low noise insulation material makes it impractical to use them in the walls of apartment buildings. Although, on the other hand, due to its light weight, neither one nor the other pipes can compare with them in this regard.

Varieties and sizes

Depending on the color of the double-wall corrugated pipe, you can easily determine its scope and purpose. In addition to this typology, corrugated pipes differ in the type of stiffness and flexibility of the walls of elements.

- Electrotechnical flexible appearance used for laying cables of various diameters from the smallest to the largest. Particularly popular is the model D 110 mm brand DKS. In turn, this type is subdivided into plastic double-layer pipes with or without internal broach.

- Hard variety Such corrugated products perfectly copes with the deformation of the soil and heavy loads in urban environments. It is used most often underground and inside reinforced concrete structures to protect communications. To it, for example, can be attributed the pressure head PND F-63, used in the device of cold water supply.

- Drainage view flexible pipes provide drainage and groundwater to protect the basement of the site, private house and any other buildings. The flexibility of this product ensures ease of installation, and a special material - resistance to water and dirt. The popular size of perforated drainage pipes for many manufacturers is considered to be a two-layer HDPE 160 mm.

Since the double-walled pipe is made of an external HDPE layer and an internal LDPE, the dimensions of its diameter are often indicated together through a slash. Standard sizes such as 110x93, 137x160, 227x200, 282x250 mm and so on are considered. Together with an increase in the internal and external diameter, the rib pitch of the corrugations also increases from 18.5 to 50 mm. The thickness of the inner layer of the product varies accordingly from 0.3 to 5 mm. In addition to the usual standard diameters, many manufacturers have the opportunity to create double-walled pipes of special diameters, for example, 200, 300 or 1200 mm.

Subtleties of installation

It is worth considering an example of the installation of double-wall pipes, which are used to protect various cables from moisture and mechanical damage when laying in a hidden way, for example, underground. A pipeline of such corrugated elements is a multitude of pipes interconnected by couplings up to a certain length. In the process of laying, in addition to the basic elements, a number of auxiliary is required - these are couplings, plugs, rings and adapters.

Couplings are designed to connect between each other pipe sections of the same size, and adapters - different.

Plugs are used as protection of the free ends, rubber sealing rings - to ensure a tight connection of the main elements with additional ones.

It is worth paying attention that inside such pipes it is possible both separate and joint laying of cables for power, signal, electrical, optical and control cables. However, in these cases they are not allowed to be tightened if the shell is jute or impregnated with bitumen. Laying is possible only in cases where the cables have lightweight protective sheaths.

The distance from the top of the pipe for laying the cable to the ground surface should be not less than 1 meter under the roads and not less than 0.4 m under other surfaces. Such depth will provide additional protection from external influences.

The width of the burrowed trenches should be calculated taking into account the total diameters of all the pipes to be laid and the gaps between them. In addition, the width of such a trench on top should be performed 0.1 m further than the bottom to ensure the slope of the walls. The bottom of the trench before laying the elements should be filled with a layer of sand and leveled.

Laying sections of corrugated pipes should be carried out with caution, especially when parallel placement of several elements. In this case, it is recommended to use clusters in which pipes are installed to provide the necessary distance between them, even after backfilling.

To check the quality of installation, you can drag a smooth wooden cylinder in the cavity sections. Backfilling of pipes is carried out in layers along the entire length of the trench: first it should be a layer of sand or soft soil, and then the previously extracted earth with the condition that there are no large stones in it.

If you compare two-layer corrugated hoses made of LDPE, HDPE and PVC with metal, concrete and asbestos cement, then the first to show such significant advantages as:

- low cost of products and auxiliary elements for installation;

- the lightest weight, which means simplicity of work, saving time and effort of employees;

- These products combine high strength characteristics, flexibility and high service life.

How to choose a drainage corrugated pipe, see the following video.