We select the safety valve for the water heater

Water heaters are installed not only in private homes that are not connected to the central water supply, but also in city apartments. The possibility of self-regulation of temperature and a comfortable existence during the period of scheduled maintenance are the advantages of apartments and houses with boilers. Independent installation of such complex equipment requires strict adherence to all rules of connection and safety. Since the electricity in the water heater is combined with practically boiling water, it is necessary to have a safety valve.

Special features

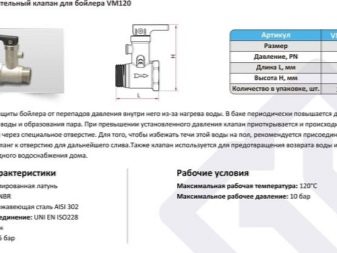

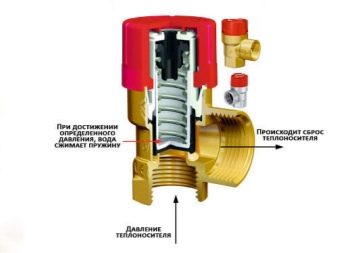

A safety valve for the water heater helps prevent overpressure inside the appliance.When the fluid is heated to certain temperatures, the device should turn off the heating at a temperature control signal, but in rare cases the sensor may not work or simply break. The design of the boiler involves tightness and closed taps, so an explosion may occur if the water overheats and produces steam that occupies a larger volume. The safety valve allows, in such a case, to release pressure to the standard values of 10 bar and to normalize the operation of the entire system.

The functionality of the safety valve is not limited to this alone. It also prevents the flow of water from the water heater back to the supply system when it is empty. Any fuse consists of a body, a rod with a handle at the top, a spring and a plug. At both ends of the casing there is a pipe thread with dimensions ranging from 1⁄2 inches to 3⁄4 inches depending on the type of product.

Kinds

There are practically no special differences between the many types of safety fittings for a water heater.

Most often they are divided into three groups depending on the volume of the heating apparatus.

- Valves for boilers of no more than 50 liters.This category includes standard disposable valves. They are almost always non-separable and their service life is quite small. But their low cost allows, without any difficulties, just to change such devices once a year.

- Valves for boilers of no more than 200 liters. More serious devices that professionals recommend installing even on boilers up to 50 liters. They consist of several valves for various purposes and an additional nozzle for the supply of sewage.

- Valves for boilers over 200 liters. These are serious devices of complex configuration, including a pressure reducing valve and a device for draining water and various adapters. Most often, such valves are installed on large industrial heaters and are rarely installed even in large private houses.

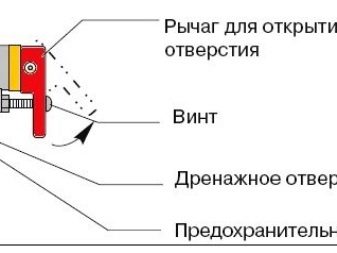

In addition, safety valves may vary in the presence and operation of additional structural elements. For example - the descent handle.

With this knob, the valve is checked as follows:

- Lever mounted vertically.

- He pulls the spring.

- Spring opens the flow of water.

This check should be carried out at least once every couple months. With the help of the trigger lever is also carried out a complete descent of water from the tank. To complete the flow of water, the handle must be kept until it drains completely.

In some models of safety valves, such a lever can be fixed with a special screw, preventing spontaneous opening in the case when the spring is weakened. There are also valves without waste construction of forced discharge of water. Most often they have a cap planted on the threads. Through it, the valve can be cleaned of scale and blockages.

On the high quality of the purchased product said marking applied to it. For example, an arrow must be engraved on the case or drawn to indicate the direction of flow of the fluid. Also, the body should be marked with information on the maximum allowable pressure that the valve can withstand. Even professionals will not be able to distinguish a valve by four and six bars if information on this is not in the accompanying documentation. Of course, such a device will have a higher cost, but the priority should still be the quality of the entire system, and not its price.

In addition to the above, the differences may be in the shape and length of the fitting for the withdrawal of fluid. Long non-linear fitting without expansion at the end will be more convenient, since it is easier to put on the hose and fix it with a hose clamp. In addition, sometimes instead of a safety valve on the home boiler put a subversive. It is designed to quickly remove water in an emergency and it is not possible to bleed the liquid several times with it. Although the functionality of these constipations is very similar, one cannot replace the other.

Safety valves for a boiler are often called a check valve, but in reality this is a completely different device, although they are similar in appearance. The check valve is responsible for the unidirectional flow of water, and the safety valve protects the pipe and the water heater from damage under overpressure. Installing a reverse locking device instead of a safety device may cause damage to property and health of residents. A device of unidirectional water flow cannot stop the heating of the liquid above the boiling point if the thermostat fails and does not prevent an explosion inside the device, which will destroy not only the boiler, but also the walls of the room.

Principle of operation

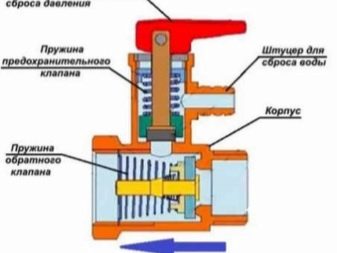

Standard heater fuses consist of three separate valves:

- safety valve itself (in rare cases, subversive);

- check valve;

- drain valve

The safety valve includes a metal rod, a plug at its end, a powerful spring and a fitting for draining the fluid. As soon as the pressure inside the boiler exceeds the value specified in the documents, the device is triggered, the rod will compress the tight spring and it will open water to the fitting, through which it will flow out. It happens so smoothly that the flow of water is just a large number of drops.

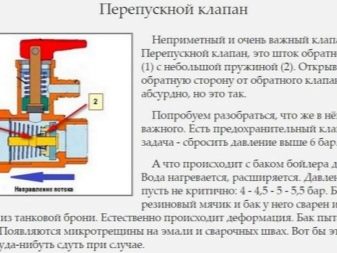

The check valve includes a plastic rod with a rubber plug at the end and a weak spring. Unlike plumbing, the check valve of the boiler is not designed to hold the pressure of high pressure water and serves as an ordinary valve, so the spring is so weak. It just does not allow water to flow into the pipes in case of an emergency or when the water in the central water supply is disconnected.

The last but very important valve is the bleed valve. It consists of a check valve stem and a small spring.He works "on safety net" safety. When the pressure approaches critical values, but does not cross them, the drain valve is able to normalize the pressure inside the heater when the tap is turned on or the toilet is flushed. When the water in the pipeline slightly lowers its pressure due to this, the drain valve opens and the excess of almost boiling water flows back into the pipe.

Installation

Before putting the safety armature on the installed water heater, it is necessary to study the offer of the construction market and choose a quality product.

Good valves have several distinguishing features.

- The body of a good unit is made of brass alloy, seamless casting. Sometimes it is covered with nickel to protect against corrosion and scale formation. Unlike cheap copper or aluminum alloys, brass is heavier, so it is easy to distinguish.

- When you click on the stem of high-quality valves, you can see how the plug goes tight inside the case. Even its small jamming on the end is allowed.

- A bad valve can be identified by simply blowing into it.If, even with a strong push on the rod, the air goes freely, then it is better not to take the product. At the same time, if water periodically drips from the fitting of the installed constipation, this still does not indicate its breakage. Perhaps you just need to clean the stub from the draft and everything will work again.

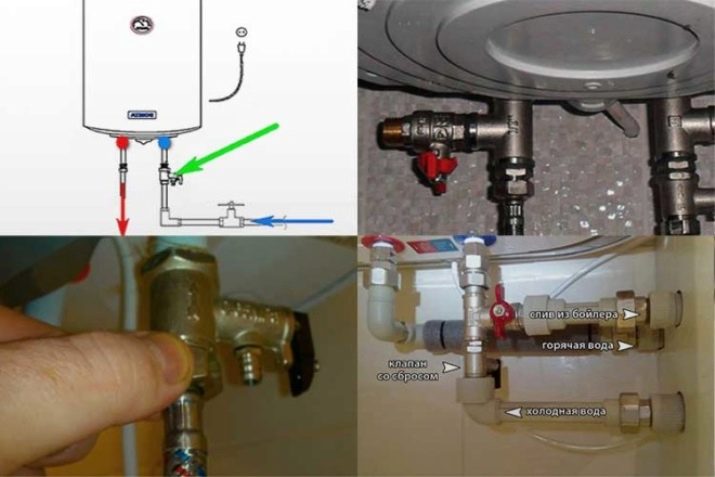

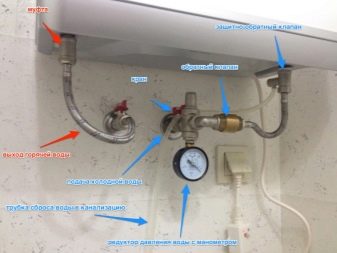

If you follow these tips, you can find the right fuse the first time and immediately begin installing it. Requirements for her are few. The valve is always installed in the pipeline with cold water. It is placed between the valve of the constipation and the entrance of the pipe into the boiler body. You can embed it directly into the water supply pipe or install a special tee at a distance of no more than 200 cm from the entrance to the heater.

In addition to the fuse, on this site, nothing should stand. Most models are installed in such a way that water enters them vertically from the bottom. An arrow indicating this movement must be affixed to the fuse body.

A PVC tube is connected to the fuse connection connecting it with the sewer pipe. It is better if this tube is transparent - you can see if the device is working properly.

The installation process itself is divided into several stages.

- Disconnect the installed boiler from the mains and drain the water from the tank. You need to make sure that the water supply to all pipes is blocked, otherwise at the time of cutting the required section you can simply flood all apartments located below.

- The valve body is purged with air to remove occasional debris and dust. A tow or FUM tape is being prepared, which will serve as a waterproofing for a threaded joint.

- The valve is screwed in with a wrench at the junction of the pipe and the boiler. The arrow on the valve body must match the direction of fluid flow. The cap nuts must be well tightened, the joint can be additionally lubricated with silicone sealant.

- Before you connect the boiler to the mains, it is necessary to conduct a pressure test connection with cold water. If after 5 minutes of fluid flow at the junction there are no drops, then everything is connected correctly.

Also, the safety and check valves are checked “for cold”. In the first case, you need to click on the trigger flag at first slightly (the first drops of water should appear), and then at full strength.When fully pressed on the transparent discharge tube, the water should flow quickly. The check valve can be checked by filling the tank completely and shutting off the central water inlet. When opening the tap in the bathroom or in the kitchen, the water flow should stop quickly. If water continues to flow from the tap for a few minutes, then the check valve requires adjustment.

Tips

Sometimes individual elements of the water heater or the entire system stops working properly. This reduces the safety of the structure and may lead to sad consequences. In this case, you need as soon as possible to find out the cause and location of the breakdown and either eliminate it yourself, or call for this specialist. Thermostats, heating elements and safety valves most often fail. And the problem in the work of one of them can instantly affect the rest. You should never install elements that do not fit in their parameters to the parameters of the boiler or have different ways of connection.

Problems can not arise by themselves, they have certain reasons.

Most often they are as follows.

- Late replacement of damaged parts. For example, a check valve should change at least once a year. It is cheap and not expensive.

- Incorrect installation of the entire system. If the insert of the fuse into the pipe is made with insufficient waterproofing or is too far from the entrance to the boiler, the system will not work as it should.

- Power surges in the electrical network may cause failure of the heating elements of the system.

- The presence of factory marriage or lack of preventive examinations. In order to choose the right heater and fuses need to very carefully examine all the information when buying. And even the highest quality device periodically needs to be checked.

- Scaling or corrosion. Scaling and corrosion on the back of the gate can cause water to leak back into the pipeline or “corrode” various connections, breaking their tightness.

The most basic faults can be divided into several types. Most often the broiler starts to flow. This can be either a manufacturing defect or a crack acquired due to corrosion.Such a tank can not be self-correct, you have to completely replace it. Water dripping from the pipe connections indicates leakage. From the safety valve, on the contrary, water should sometimes drip. If it is always dry, it should be replaced.

The second common malfunction most often is the lack of heating. Almost always it is connected with malfunctions of the heating device or thermostat. Sometimes this is how an emergency shut-off function is triggered when the boiler is constantly turned on to the maximum temperature.

Often, during operation of the boiler, the walls, the perimeter of the outlet and the surrounding space can be heated. The most dangerous in this case is heating the plug or outlet. The reason may be poor contact or breakdown of the heater. If the water heater does not work on electricity, but from the gas network, then the chimney can become clogged with ice, which will close the steam output. In this case, it is quite simple to clean it.

In case the water heater gives an insufficient amount of warm water, it is necessary to check if the inlet and outlet pipes are not interchanged. And if the hot water enters the kitchen faucet with almost no pressure, while the mixer works properly, you need to check the safety valve.It can be clogged with rust or dirt, after cleaning it, the water pressure will be restored.

A quality safety valve for boilers of no more than 200 liters installed on a standard household heater can last at least ten years. It is necessary to regularly clean it of sediment and check the performance of the entire system. Every three to four years, it is desirable to dismantle and wash it with special chemical solutions that can be purchased at hardware stores.

When installing, be sure to follow the above rules and conduct a quality check of the system with cold water under pressure. If you have any doubts about your own abilities, it is better to entrust such responsible work to professionals. After all, not only property, but also the health of all residents depends on quality work.

On why you need to install a safety valve for the water heater and what happens if you do not install it, see the following video.