Classification and use of cast iron pipes

Modern industry offers a large selection of a variety of pipes to create an effective sewage system. Plastic pipes are gaining more and more popularity, however, cast iron pipes do not give up their positions. Cast iron has quite a few supporters: it is a quality material that has been tested for decades and has many advantages.

Special features

Pig-iron water pipes were built in pre-revolutionary Russia, while everything was done “for centuries”, however, in the second half of the last century, theories of economic expediency came out on top. Engineers of the time decided to build pipelinescalculated for a century and a half of use, it does not make sense, because already after a couple of decades, the city will expand, become frustrated and will have to build new highways.

It was at that time that steel pipes were widely used - it is a cheaper material, besides its production and installation is much simpler than the construction of cast iron structures.

Unfortunately, many plans remained plans, and steel pipes still supply water to many houses, despite the fact that the useful life of a pipe laid in the ground does not exceed 40 years. After this time, numerous fistulas appear in their walls, through which water losses can reach 20%. Moreover, the steel pipe from the inside is overgrown with rust and lime deposits, for 20 years the clearance is reduced by 3-4 times, and this, in turn, leads to a sharp drop in pressure and the degree of permeability of the aqueduct.

If we compare cast iron with other materials, the picture is no less eloquent. For example, ceramic pipes are not as strong as cast iron, they can break even from a blow of medium strength, and there are no opportunities for their subsequent restoration. That is why when using such variants of pipes, it is necessary to install additional structures that reliably protect against soil pressure - All this leads to a significant rise in the cost of the water supply system as a whole.

Pipes made of a mixture of cement and asbestos have a fairly low cost, but the material can be damaged even easier than ceramics. Yes, and plastic products also do not differ in the same strength as cast iron, they are destroyed when exposed to high temperatures and direct ultraviolet rays, in addition, the material may be damaged by rodents.

That is why in recent years, cast iron began to return its position, due to its extremely high consumer characteristics:

- the period of effective operation of cast iron products is at least 100 years;

- the internal surfaces of the pipes practically do not overgrow;

- the material is resistant to corrosion due to a special anti-corrosion coating;

- cast iron has high tensile strength and tensile strength;

- characterized by slight thermal expansion;

- differs in high sound insulation;

- resistant to mechanical and most chemical types of damage;

- does not ignite spontaneously and does not sustain combustion;

- resistant to temperature fluctuations;

- Made from environmentally friendly raw materials.

However, like any other material, cast iron has its drawbacks and its fragility can be attributed to the most tangible. This feature is non-standard for metals, since they are generally plastic. That is why in case of serious movements in the ground, where the steel is simply deformed - cast iron will simply burst. This is due to the fact that the structure of the alloy contains a large number of various carbon additives, which modify the material.

However, in fairness it should be noted that the cracking of the cast-iron pipe is possible only if the pressure of the soil, which it is experiencing, is of a constant rather than a one-time nature.

One more minus of cast iron is related to its weight, such structures are much heavier than steel and especially plastic, which is why installation of cast iron pipelines is possible only with the use of suspended equipment.

The weight of the cast iron is a consequence of its structure, since GOST prohibits the casting of pipes with a diameter of 10 cm with a wall thickness of less than 1 cm. In case of damage to the pipeline, the cracks with which the material is covered can be non-uniform, therefore it is not possible to repair them by simply cutting the deformed section, this can lead to its complete destruction.

And, of course, the price of the material also affects its popularity. Cast iron itself cannot be called an affordable option, and its transportation and installation features require additional, and quite considerable, effort, time and money.

Kinds

All cast-iron pipes are divided into bell-shaped and socketless:

- Flange considered to be the “oldest” type of pipe, but at the same time relevant and popular to this day. They are not subject to rust and have a long period of operation. The disadvantages of bell-shaped products include their fragility, which significantly complicates the conduction of pipelines.

- Socketless The pipes are made of cast iron with a high percentage of graphite, their internal walls are covered with a special composition based on epoxy resins, so that silting and layering of lime deposits is almost impossible.Such pipes have a wide range of use, thanks to which they work efficiently even in contact with aggressive media. In addition, SML pipes do not need additional protective mechanisms that save them from vibration and the destructive action of fire, since these products themselves are durable and resistant to negative natural factors.

All pipes manufactured from cast iron can be divided into several categories. Let us dwell on each of them:

Cast iron pipes with spherical graphite (VChGG and CHSHG)

Such products are manufactured by centrifugal casting with the addition of spherical graphite. These pipes are widely used in the construction of pressure systems to ensure the delivery of industrial and drinking water, as well as for the arrangement of heating systems, boiler rooms and water supply pressure sewage systems. They are optimal for laying underground.

ChShG withstand an internal pressure of more than 1.5 MPa, they are not prone to corrosion and rust, they are distinguished by their strength and plasticity, as well as resistance to temperature fluctuations and ease of installation.

The water passing through the pipes with graphite does not change its physico-technical and biological properties. At the end of the operating period, such pipelines are easily dismantled, and the material itself must be disposed of.

Non-pressure pipes

They contain plastic graphite, and their outer and inner walls are covered with an anti-corrosion material, most often bitumen. To facilitate the installation of these pipes, one end of the product is equipped with a socket.

Such variants of the pipeline are used for the construction of free-flow systems of economic and fecal sewage in commercial buildings and houses.

Sewage pipe

Necessary to connect the riser with the atmosphere, it is designed to prevent the occurrence of vacuum over the wastewater stream.

Such a segment is obligatory for installation in the following situations:

- if the house has two or more floors;

- sewers in the building have a diameter of 50 mm;

- The building is equipped with a swimming pool, which periodically releases waste water in a large volume.

Pig-iron flanged pipes

The pipes, both ends of which are smooth, and flanged adapters are used to connect them together.These devices consist of two parts: directly flange with a piece of pipe and a small coupling, which is made of stainless steel. During installation, the adapter flange is connected to the pipe flange and attached to the coupling.

Finned economizer tube

It is used in the arrangement of the heating system and the installation of radiators.

Dimensions

Special attention deserves the question of the size of pipes made of cast iron. When it comes to plumbing, as well as sewage, the size of the pipes is large and even crucial. It depends on the diameter, where the product is used, and how much liquid a pipe can carry per unit of time.

For example, cast iron pipe up to 100 mm can only be used for domestic sewage, because if you use it when installing common risers, it will not withstand all the pressure and simply clog. By the way, this is a very important point, which in many ways distinguishes sewer systems from water pipes. If for any reason the latter is clogged, then the only inconvenience that the household will encounter is the reduction in water pressure. However, in the water supply chase clean water, but in the sewage system - fecal, so if there is a blockage, then the whole sewage system will clog and stop functioning.

It is important to adhere strictly to the specification of diameters and use pipes for their intended purpose.

- For domestic sewage There is enough pipes with a diameter of 100 mm, and for small sanitary facilities, products with a diameter of 50-70 mm are suitable at all - they are installed at the connection points of a bathtub, sink or toilet bowl.

- For mounting risers 150 mm pipes should be preferred.

- In the external sewer use a variety of sizes, for example, for medium branches take pipes with a diameter of 150 mm, for fixing several sections between them take pipes of 300 mm, but for trunk systems should purchase products with a diameter of 800 mm and more.

In the current State Standards contain tables in which you can find all the allowable dimensions of the pipes of each type.

Installation

There are several basic methods for connecting cast iron pipes to each other. As a rule, they are not very different from the installation of plastic products, except that in working with cast iron cooking is not allowed.

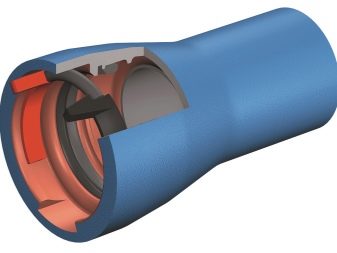

The most commonly used method is the connection of pipes into a socket. A spout is a section at the end of a pipe that has a slight extension, it is used to connect pipes along a chain.On the one hand, the bell has the usual size corresponding to the diameter of the pipe, and on the other, the workpiece expands by 6-8 mm. This is necessary in order to be able to easily insert into the expanded part of the pipe another one, the same, but with a normal end.

Such compounds are simple, convenient and practical, with them there are no problems, and The standard scheme includes several stages:

- preparation of necessary materials and the terrain in general;

- installation of the first pipe;

- fixing the second and subsequent blanks;

- fastening to the sockets;

- sealing joints.

The pipes are sealed in different ways. In former times, “grandfather's” methods were used, such as, for example, flax. Now actively used silicone sealants. The undoubted advantage of silicone is the ability to form an airtight, but at the same time light and cheap seam without much effort.

The natural thing to do is to apply the composition in several layers and wait for it to dry. If the opening is quite large, then it is worth carrying out the work in several stages. This scheme is used to connect elements of external and internal sewage, as well as to connect toilets, sinks and other similar installations.For a pipe-free connection of pipes it is necessary to drill them, and then use fasteners: saddles and cuffs.

In modern homes, quite often there is a need to install the same toilet in a situation where its output is made of a different material - plastic or rubber.

Everyone knows that the transition of pipelines from different materials in their structure is dangerous, however, in the case of cast iron there are no problems - To connect the elements into a single system, special adapters are installed, and then they generously seal the joints silicone based formulations.

For the repair of pipes, their caulking and caulking is necessary - they can be easily held with your own hands.

Manufacturers

Despite the fact that all over the world they are actively moving from iron to steel, the demand for it remains consistently high due to its excellent strength, therefore, large metallurgical companies are not in a hurry to curtail the manufacture of iron products. In Russia, cast iron pipes are produced by large industrial holdings.

Lipetsk Pipe Company

Metallurgical production "Svobodny Sokol", located in Lipetsk, is still the only domestic producer of pressure pipes.Here are made of cast iron pipes with spherical graphite by centrifugal casting. Production capacity is 280 thousand tons per year.

Some time ago the plant was declared bankrupt and reorganized into LTK, and the production of pig iron was suspended. Currently, the metal that is used to produce cast iron pipes is purchased at a neighboring NLMK, as it turned out, the use of purchased raw materials is more profitable than the production of its own.

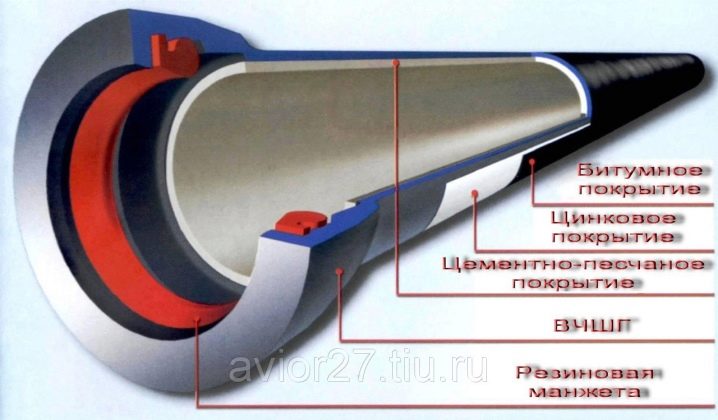

Alternatives to pipes that are produced in Lipetsk, there is no worldwide. They are covered with a zinc compound on the outside and protected by a sand-cement layer inside. The quality of water coming from such water supply systems is invariably excellent, so the high price does not become an obstacle for those who want to get a quality product.

The products of this manufacturer are exported.

Sinar Pipe Plant

This plant specializes in the production of pipes made of iron and steel, along with a number of other metal plants this company is included in the TMK group. It was here that for the first time in the world, cast-iron pipes 10 meters long were produced. Products are presented in a wide range of products,thanks to which they cover a wide range of consumers - from utility companies to large oil refining holdings.

Modern industry requires that cast iron be used for the pipelines serving it. Of course, the cost of such systems is much higher, but only they most meet the requirements of manufacturability and safety of the output systems.

Tips

Pipelines are installed for decades, the comfort of people and the efficiency of life support systems of residential and commercial premises largely depend on their functionality. That is why it is very important to choose a product of good quality.

- The first thing you should pay attention - the proposed range. A reliable seller always has a wide choice of both the pipes themselves and the associated fasteners and fittings (nurses, etc.). It is quite convenient if both pipes, and tow, and other materials used to create airtight joints are used in one place. This is not only convenient, but also beneficial, since the purchase of goods in several places significantly increases transport costs.

- It is very important to check all the proposed terms of payment and delivery of pipes, as well as the warranty obligations of the seller and the availability of the possibility of returning defective goods with subsequent compensation of costs. And, of course, it is necessary to ensure the proper quality of cast iron pipes.

- It is necessary to carry out an external inspection and ensure that there are no external defects: deformations, chips, cracks, metal influxes and slag layers. These defects must be absent both outside and inside.

- The dimensions of the products must correspond exactly to the existing GOST. The deviation should not exceed 2 mm, and the maximum error of length should be 0.9% of the nominal value in those. conditions.

Even in the production of cast iron pipes covered with a special mixture based on bitumen, it causes the threshold for the conversion of a solid layer into a softer at a temperature not lower than 60 degrees. It is not possible to measure the change in the required plasticity outside the laboratory, however, it is quite easy to verify in the absence of cracks, blisters and other defects.

To do this, use several techniques:

- At a temperature not lower than 15 degrees of heat, it is necessary to press a white sheet of paper tightly to the outer surface of the pipe, but without excessive pressure.After the sheet is separated, no traces should be left on it.

- The second method allows to evaluate the reliability of the anti-corrosion coating. To do this, it is cut in the form of a grid so that there is a distance of 40-45 mm between the lines. If the coating remains complete, then the layer is characterized by high quality, but if it starts to peel off, it is worth buying goods from another seller.

For information on how pipes are made from cast iron, see the following video.