Plastic roof gutters: how to calculate and mount yourself?

The roofing of a building of any type includes a number of mandatory elements. In this list there are components that provide protection from moisture by timely removal of water. Such products include drains, which are most often made of plastic.

Features and elements

In the modern construction market, more and more products and components are presented in the form of products made of plastic, which is a worthy competitor to the metal. A similar trend has affected the drainage system, the main function of which is drainage of precipitation from the roof, as well as the creation of a certain protective barrier from moisture for the facade of the building.

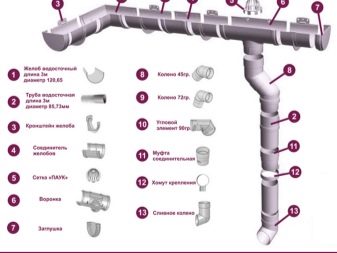

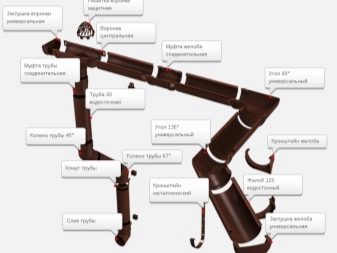

Drainage structures, regardless of the type of raw materials used for their production, in the basic configuration contain a standard set of elements. Gutters are arranged on the roof, which are fixed to the base with the help of special fasteners and brackets.

To increase the visual appeal, the system is additionally equipped with internal corners and plugs.

Below, a funnel settles on the roof, the main task of which is to direct the flow of water going down the pipes. The pipes themselves are installed and fixed on the building on the brackets and clamps. The lower part of the system has a drain elbow.

A separate mesh of the drainage system is considered to be a special mesh for a funnel., which eliminates the ingress of large debris or any foreign objects. The part requires a certain care, which is to carry out regular cleaning, so you can reduce the risk of water overflow, avoid breakage of the structure and remove accumulated pollution. Cleaning the mesh should be carried out at least once every six months.

Experts recommend periodically inspect the entire drain structure, to avoid situations involving breakage or clogging, which will eventually lead to system malfunctions.

The design of drainage systems on the market today may have a different shape. Manufacturers offer products of the following forms:

- rectangular;

- round;

- square;

- made in the form of a trapezoid.

The most common and familiar option is considered to be a round drain system, it can be found on most modern houses. The gutters that are available on such gutters are made without stiffeners. This configuration of products suggests a slightly different specificity of installation, which consists in the use of special clamps. They provide high-quality fixation of parts with each other.

Gutters of a rectangular type visually resemble drainage drains that settle pavements. Such products are made with stiffeners, in addition, they have an impressive volume. This feature makes it possible to operate a system of plastic drains that can cope with a large load.

Square and rectangular pipes are used for closed-type structures, which are installed in the roof during the construction of drainage funnels.

The popularity of plastic gutters is explained by the reliability of the raw materials, as well as the high level of resistance to contact with various chemical compounds. The material does not need any protective coating or additional surface treatment, since it does not tend to corrode. Such a distinctive feature of plastic products for water drainage from the roof provides the system with a rather long operational period.

To give the required color and shade to plastic products, special uniform processing of the material is used with a recess into the base of 3-5 mm., thereby increasing the resistance of products located on the roof, to the loss of color due to exposure to ultraviolet radiation. Products are painted in bulk, which makes visually imperceptible scratches or defects on the base, having a small size.

It is very easy to distinguish low-quality products from the presented range.Products in which only the top layer is painted, most likely, were made in artisanal conditions. Such products are not worth buying. There is a wide range of products in different colors on the market, which allows you to purchase elements for drainage that match the color and type of roof.

When choosing plastic drains there is no need to regularly paint or putty products. PVC drains are a construction made of high impact raw materials, which include plasticized and non-plasticized polyvinyl chlorides containing certain additives.

Among them are: coloring pigments, plasticizers, which increase the mechanical resistance of the material, as well as stabilizers and UV additives.

Advantages and disadvantages

Plastic drains have specific features that increase the demand for products. It is worth noting the following advantages of PVC structures:

- high level of noise insulation, which exceeds the same indicators of metal roof drains;

- resistance to rust and corrosion;

- plastic is not destroyed by contact with an aggressive chemical environment;

- minimum weight of the structure, which reduces the load on the building and the roof;

- simple installation of the system, which can be done by hand;

- any item that has become unusable can be easily replaced;

- material is resistant to temperature fluctuations in the range from -40 to + 50ºС;

- the cost of the PVC drainage system is several times lower than the metal construction;

- raw materials have a high level of resistance to moisture;

- UV resistance;

- plastic drains can be used for all types of roofing.

Along with positive qualities, plastic drains have some drawbacks, these should include the following:

- low resistance to mechanical damage, due to which such structures are not recommended to be installed in high-rise buildings;

- a part that has been damaged is no longer repairable. It must be replaced with a new one;

- large range of thermal expansion of raw materials;

- designs that have a rubber seal in their configuration require frequent replacement.

Plastic and metal: pros and cons

To compare metal and plastic drains, It is necessary to analyze several characteristics of products.

- Mass system. PVC designs are lighter than metal products. Proceeding from this, plastic drains are more popular, since they do not require additional reinforced fastening on the roof.

- Resilience to mechanical stress and strength. In this case, plastic figures are inferior to metal products.

- Resistance to corrosion. PVC drains are not susceptible to such destruction, and, for example, galvanized elements have a low level of moisture resistance. However, in this case, you can give preference to a system of zinc, aluminum or metal-plastic. The only disadvantage of such products will be their high cost.

- Tightness. Plastic is more resistant to leakage than metal.

- Operational period of production. Manufacturers of plastic constructions guarantee a service life of about 20–30 years. Steel products usually function effectively for about 20 years, and the system in which the components contain a polymer coating is the most durable, its operating life is about half a century.

- Resistance to temperature fluctuations. PVC products perform well in the temperature range from -40 to + 50ºС. For metals, this indicator is much better - from -50 to + 120ºС. Therefore, in harsh climatic conditions, it is necessary to give preference to metal gutters.

Comparing the characteristics of the two materials, it is rather difficult to give preference to any particular variant, since the choice must be based on the individual features that are in each specific case.

Heating issue

To reduce the load that snow masses have on the roof, the structure is heated. The presence of such a system makes it possible to eliminate the accumulation of icicles and ice on the components of the drain during periods when thermometer indicators fluctuate. In the role of the element for heating is a special cable. It generates heat, under the influence of which there is a thawing of snow and ice on the roof, and the drainage system ensures the removal of the formed water on the surface of the building.

It is worth noting that the anti-icing system has a high cost, however, according to consumers, their price at times pays off the benefits and effectiveness of the elements.

In some cases, homeowners solve this problem by laying the cable only on the surface of the roof. But its availability for productive melting of snow will not be enough, which will serve as a cause of clogging of the gutters, as a consequence - the formation of overflows and breakdown of the entire system.

It is necessary to take into account that independent work is associated with a certain risk., since even a small error during installation can lead to a short circuit. From which it follows that these works should be trusted only to professionals. The cost of the device for heating and work on the arrangement is calculated taking into account the area of the roof, the brand of the installed device and the individual characteristics of the climate.

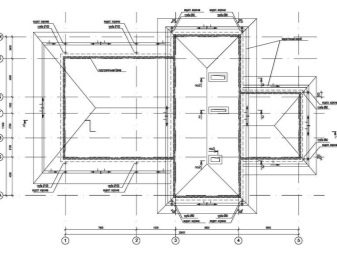

Scheme and calculation

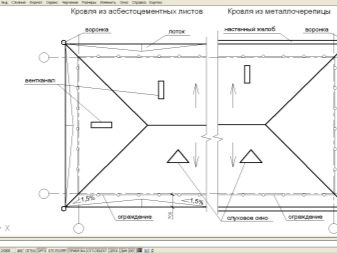

Regardless of the design and shape of the roof of the building installation of the drainage system is necessary. But, before you start buying all the components of plastic drain, you should perform measurements of the roof area and make calculations, based on which you can determine the amount of material required for work. First you need to measure the width and length of the roof slopes, as well as the height of the building, given the ledge ledge. Width and length will help determine the area of the building.

An important nuance in this matter will be the architectural component of the roof structure, which may require additional measurements.

In order not to be mistaken with the calculation of the number of components, the following points should be considered:

- the distance between fasteners for gutters should be 50–70 cm. For large gutters, it is best to take the minimum step;

- The most common length of the gutter is 3 m, however, you can find products with a length of 1 m. In the course of calculating the required number of parts, you should not forget about the plugs. A conventional dual roof requires 4 pieces, and unusual and multifaceted systems need individual calculations;

- in addition, count the number of required funnels. To proceed in this matter is of the recommended amount - 1 element per 10 meters of area. However, if the area is more than 50 m², the number of products will be different;

- pipe length is calculated from the height of the building. Products usually have a length of 1 to 3 meters. In addition to pipes, it will be necessary to purchase several knees in order to circumvent the eaves overhangs. The most suitable diameter of pipes for drains is 80 or 90 mm;

- the last step is to determine the number of fasteners.To proceed in the calculations follows from the following requirements - 1 bracket per 1 square meter;

- drain tribes need as much as purchased funnels.

If you plan to collect rainwater in the tank, then the knee in the design is not necessary, it will be enough to leave the pipe at a convenient level and place a container under it.

Installation and installation

The price for installation of drains can unpleasantly surprise the consumer. At the service of experts, it is worth resorting only in the case when an expensive system was purchased and there is a risk of damage to the product during an unskillful installation. In addition, a special approach to the installation of gutters requires already covered the roof of the building.

Without sufficient practical experience in performing works of this nature, it would be best to resort to the services of professionals, since there is a high probability of damaging the roofing material during the installation of gutters. After completing the calculations of the required number of materials, and buying them, you can begin to install plastic drains.

Installation of the structure is possible at any time of the year.

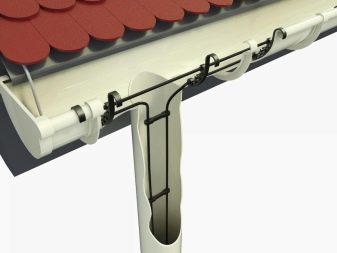

Work on the arrangement of gutters is best done even at the stage of creating the sheathing of the roof, when there is the possibility of fixing the brackets to the rafters.Technology device drainage system is performed in a certain sequence.

The general order of works is as follows:

- The first step is to attach the brackets to the structure that will fix the gutters. They can be installed on the eaves board or directly to the truss system;

- After installing the fasteners, the gutter is laid. It must be located at a certain angle. To facilitate this process, you can stretch the cord between the extreme elements of the structure, which will serve as a certain guideline in the course of the work. Upon completion of the above actions, you should check the reliability of fixing parts, as well as check the quality of bonding of the components of the structure with each other;

- after completion of the work with the gutters, proceed to the arrangement of the craters in the places where their location was planned. To install them, use a hacksaw for metal to cut openings of the required diameter, where the funnels themselves are fixed with the help of glue;

- with the help of glue-sealant stubs are glued to the edges of the gutter;

- further, all the components are connected to each other - the drain elbow is connected to the funnel and the pipe. For these works, you also need to use glue. The pipe is fixed to the wall, using clamps for fastening;

- you should not forget about an important element of a drain - protective grids. They are placed on their seats after fixing all the details among themselves;

- the last installation of the drainer is at the bottom of the drain.

In some cases, when purchasing plastic drains in a complete set to a set, manufacturers attach a scheme with step-by-step recommendations to the installation and subsequent maintenance of the system.

There are many options and ideas for creating drainage with their own hands from improvised means. Such structures will also be able to sufficiently cope with their functional tasks. But the features of the system are likely to require more attention, frequent repairs and cleaning. However, it is worth considering that in the modern construction market there is a lot of various drainage plastic systems of good quality, made by domestic and foreign manufacturers,which will be affordable for most homeowners.

You will learn more about how to calculate and install plastic drain, from the following video.