Rules for replacing the pump in the well

Pumping equipment for wells is an important tool designed for water intake. The efficient operation of the entire water supply mechanism depends on what type of pump is selected and what characteristics it has.

Special features

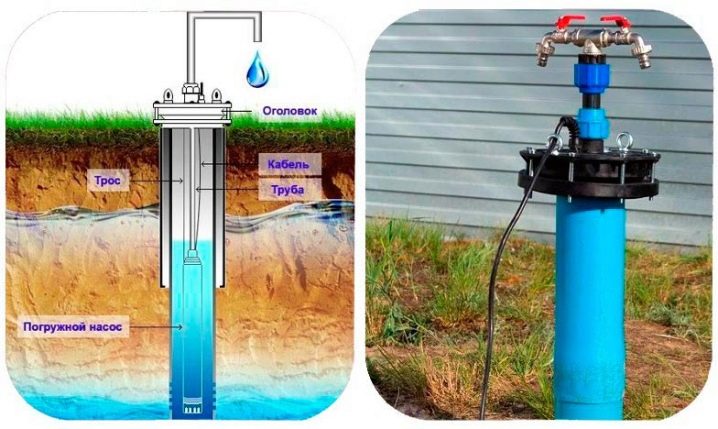

When buying a submersible pump, you need to pay attention to the choice of the cord for the well, which can withstand the pressure and water load several times more than the weight of the device itself. In addition, you need to take into account the distance at which the suspensions will be mounted. To prevent the unit from being sucked in, it is necessary to place it at a distance of 10–11 cm from the beginning of the inlet. If the pump is lowered to a depth of more than 10 meters, then the suspension should be mounted on a spring to dampen the vibration, for example, a medical band can be used. Only here you should not replace the suspension with an iron cable, which can damage all the coupled cables and cords on the device body.

Next, you need to take the suspension from the caprone, the electrical wire and the pipe of metal-plastic material and fasten them with tape with a step of 70–130 cm. The first fixture is made at a distance of 200–300 mm from the beginning of the pipes. A screw connection is not the best solution for connecting a device. They corrode over time and slowly deteriorate, affecting the operation of the entire pump.

It is worth paying attention to the flange connections, during installation of which the fastening bolt is located on the top and the nut is on the bottom. If the bolt falls into the well, the pump may stop working.

To the base plate install the upper part of the pipeline. Next, produce a check valve, knee, valve, pressure gauge. The suspension is attached to the crossbar. It is important when lowering the pump into the well to prevent its contact with the walls. Rubber ring can protect equipment case. The gauge can help determine the insulation resistance of the motor windings, check whether the device is sufficiently immersed in water, and you can also check in advance the functioning of the engine under pressure.

The pump is immersed to a depth of 30 cm from the dynamic water level in the well. This level refers to the distance from the surface to the water surface. From the moment of the start of pumping water from the water intake, the mark at which it stops, and will be dynamic. Acceptable depth from the equipment to the bottom should be about 1–2 meters. Float switches are an additional assistant to the pump. They stop the engine when the water level in the well reaches its critical level.

Replacing a well product in a well with a depth of 80 meters is quite difficult to do, but expert advice will help you to do it yourself.

Causes of failure

Like any mechanism, pumps can also break and fail. The main thing is to understand what led to such consequences as to eliminate the problem as quickly as possible. Common common causes that indicate the need to replace a pump are the following:

- failure of the motor, which ensures the functioning of the pump. Typically, signs such as a complete lack of noise when turned on, the presence of noise, but the lack of water in the pressure pipe indicate a problem;

- cable malfunction that could break or burn.Breakage of this element leads to a power failure of the pump;

- if the cord is broken, which is responsible for keeping the equipment at a depth in the well, the pump may break and fall to the bottom of the well. In this case, you need to contact the specialists who will reach the pump in time and fix all the problems;

- another cause of failure may be damage to the pipe, which is connected to the discharge pipe of the submersible pump;

- abrupt termination of the pump due to improper installation.

All of these causes of a pump breakdown have a different effect on it. Therefore require different methods of repair. The main thing - if a problem occurs as soon as possible, find out its source and eliminate it. Timely actions will stop the further development of damage and increase their impact on equipment. The sooner the pump is repaired, the less negative impact of the damage will have on the operation of the entire system.

There are cases when complete repair is not possible, while some parts of the pump need to be replaced with new ones. Depending on the type of fault, the replacement of parts will take place in different ways.If there is a problem when lifting the pump from the well, then with the replacement of any element may be certain difficulties. It all depends on the depth. With a small distance of 10–40 meters, you can fix the problem yourself. When replacing an ECV pump or on a vibration device, you will have to ask for some helpers or use special technical means. Otherwise, this problem cannot be solved independently.

Body jamming is the most common type of malfunction. Such a situation may occur due to the twisting of a strongly weakened power supply cable into a kind of assembly and its penetration into the gap between the machine body and the inner walls of the pipe. The cause of this problem is mainly poor-quality installation of equipment. The cable that provides power, and the cord on which the pump hangs in the well, are not connected to each other by clamps. Only reliable fastening of the cable can reduce the likelihood of a pump jamming. Also, if this problem exists, you can push the device down. Only you need to take all actions with caution to prevent the pump from falling to the bottom of the well.

Silting as another problem causing equipment breakdown occurs only in cases where the apparatus has not been used for a long period to pump water. In this case, the pump can be impossible to get out of the pipe. Silting can occur both in the well itself and in the body of the pumping equipment. The occurrence of various obstacles in the casing will not allow to remove the pump from the well. Such a problem may occur due to the deformation of the pipe due to the displacement of the soil layers. And it may also be the divergence of the connecting joints between the lengths of pipes from which the casing is made.

In this case, in order to extract the pump from the well, you can pull it with a safety cable, power supply cable and pressure pipe, while simultaneously rotating it around its axis. If the gap already existed between the pump casing and the casing walls, then performing similar actions can be made so that in some of the positions between the hydraulic machine casing and the obstacle that appeared in front of it, an opening will be created that will allow the device to continue to be removed from the well shaft.

Any foreign object can easily get inside the well if it is not protected by a tip or a caisson. In order to extract from the pipe a submersible pump, the upward movement of which is disturbed by foreign objects, the following actions must be performed. When making jerks, the pump is lowered and then raised in the well shaft, trying in this way to push or move the foreign object to another place or position, or to lift it to the surface with the help of the created fluid flow.

These actions may not always be effective, then you should contact the specialists. People professionally involved in the repair of submersible pumps, will be able to quickly and accurately eliminate all faults.

The appearance of limescale is not the most pleasant news. The occurrence of such a problem will also prevent the pump from being removed from the well. Attempts to get the equipment will not be successful, as the limescale will deter the apparatus.

In order to extract a pump from a well, it is necessary at one time to lower and raise it with smooth movements without sudden jerks. If actions will help get the pump, then you should not be so happy. Lime deposits could remain in sufficient quantities in the well. Therefore, re-lowering the pump may fail. Only specialists will be able to clean the internal walls of the casing from the resulting plaque.

All of these problems can be easily avoided if at the initial stage you choose the correct model of the pump with a possible gap between its body and the inner walls of the casing.

How to replace?

All possible malfunctions that can occur with the pump have been described above. When a problem arises with the operation of the equipment, the question arises how to replace it. It is necessary to study in detail the rules of installation. This will help you learn how you can simplify the use and maintenance of a submersible pump in the future. After all, replacing equipment straight into the well is a little more difficult.

The first item is the fact that the holding cable must cope with the load, which is at least 5 times the weight of the unit. The cable or cord, electrical cable and piping should be connected to each other with electrical tape or plastic clips with a pitch of about 1 meter.Threaded connections should not be used to connect equipment, and it is better to give preference to the flange connection as a more reliable and stable option. During the descent of the apparatus should not allow its slightest contact with the wall. The rubber ring can additionally be used to protect the case.

The inlet of the submersible is at least 0.5–1 m from the bottom, and the pump casing is always in the water. Therefore, the lowering depth must be determined by the dynamic water level as one of the indicators.

Replacing the downhole pump in the well requires compliance with the following algorithm:

- it is necessary to disconnect the power supply going to the old device;

- it is necessary to disconnect the water pipe from the main pipeline;

- slowly and gently without quick and sudden movements to raise to the surface of the well an old pump that has served for a long time;

- after the end of the process of removing the old device, proceed to the preparation of the installation of the new pump

- slowly lower the equipment into the well without touching the walls;

- fix the cable at the base and then connect the pipeline to the line;

- connect the power supply to the pump;

- check the correct operation of the device.

Tips

Experts recommend sticking to the following tips when performing a pump replacement in a well:

- when replacing the structure, it is necessary to select high-quality equipment with advanced mechanisms that can cope with malfunctions themselves;

- in the process of installing the device is to install protection for it;

- To minimize the number of breakdowns, you need to take into account the dynamic water level. It must always remain above the pump;

- for suspension, you can use a cable or iron wire;

- when fixing the bolt, it is necessary to insert it from above, and the nut - on the opposite side;

- when installing the pump in the well, it is not worth it to contact the walls of the casing;

- while lifting the pump, it is necessary to use a safety cable, since if the device breaks down from gravity, then it will be impossible to get it.

Equipment wells for the organization of the water supply system is the most convenient option for providing a private home with water. Therefore, for a good water supply, you should purchase a good and high-quality pump, in the characteristics of which there will be the newest self-defense functions. Even if the unit breaks or becomes damaged, the replacement must occur in a specific order.

Violation of any pump replacement points can cause even more damage. If the replacement of a submersible pump in a well seems too difficult, then it is worthwhile to call the brigade of specialists who will do all the work qualitatively and quickly.

For the selection, strapping and installation of the pump in the well with your own hands, see the following video.