Features of cast iron rain grids

We all know what unpleasant consequences can be after heavy rains or heavy melting of snow. As a result of a large accumulation of moisture, we are expected not only by muddy pools, bogs, but in some cases the formation of mold, for example, in such areas as the foundation or cellar.

Progress does not stand still, and people have invented a whole system of drain drains, in which the presence of drainage trays, which can collect all the unnecessary moisture at the right time, plays an important role. On top of the drainage trays, special gratings are often installed, which are also called storm drains (popularly, storm drains). Such grids prevent large debris from entering the drainage system.

Special features

In addition to protection from the ingress of stones, leaves, branches and other large debris, storm nets:

- help to eliminate traumatic cases, ensuring the safety of transport, people and animals;

- protect the sewers themselves from damage by road transport;

- due to the fact that they are placed level with the surface, they do not interfere with the transport, but create a practical section and withstand considerable loads;

- give a more attractive, aesthetic image of the streets and landscape design.

Types of grids for drainage trays

On the modern market there is a huge selection of gratings that fit any type of drainage channel, including a complex and unusual design. The difference between the lattices from each other lies in the basic material of manufacture, which will determine the range of use of storm drains. Gutter construction can be installed independently, as well as its repair.

Steel and cast iron grates are used on most of the linear effluent within the city, where there is continuous friction and increased pressure. For example, cast iron storm water trays easily withstand loads of up to 25 tons.

Stainless steel gratings are used on the territory of gas stations, industrial plants, roadsides, in general, everywhere where good anti-corrosion properties of the material are required. This type also includes products made of galvanized steel.

Plastic grids - although they are strong, still set them in locations with low loads, for example, in the backyard, suburban areas, in parks, on footpaths, children's playgrounds, and so on.

Products made of copper mainly perform the function of decor.

The choice of water intake grids for drainage should be approached carefully, taking into account the intended scope and location of their use.

Benefits

As already mentioned, there is a fairly large selection of storm nets. But one of the most classic and versatile remains still cast iron. In the process of building drainage systems, cast-iron gratings are used, differing in size, shape and quality of the material.

Solid cast iron showers have good properties and have many advantages:

- good strength and corrosion resistance to various influences;

- long service life of the product (at least 50 years);

- excellent resistance to frost and sudden temperature changes;

- environmental friendliness;

- good culvert properties;

- guaranteeing the best security of the drain system;

- ability to withstand high and constant loads.

Among the shortcomings of cast iron products, only a very large weight and not always an attractive appearance, associated with the nuances of the production of casting grating, are distinguished.

Production specifics

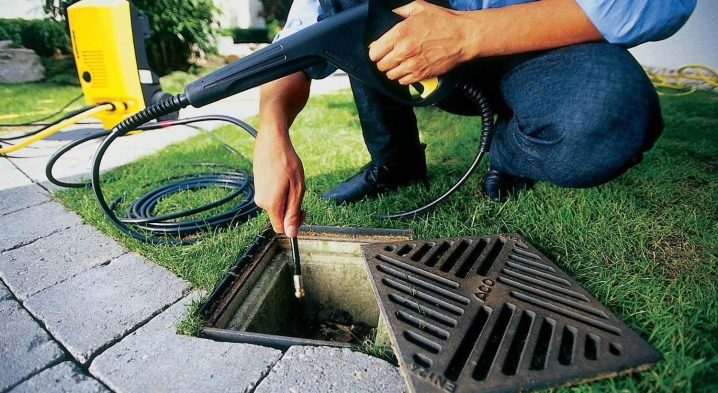

Most often, in the production of cast iron gratings, a casting method is used. The cells of the product itself are designed so that water and mud flows are well passed through them. Thanks to such gratings, easier and more convenient access to cleaning the sewage system in the event of clogging is provided.

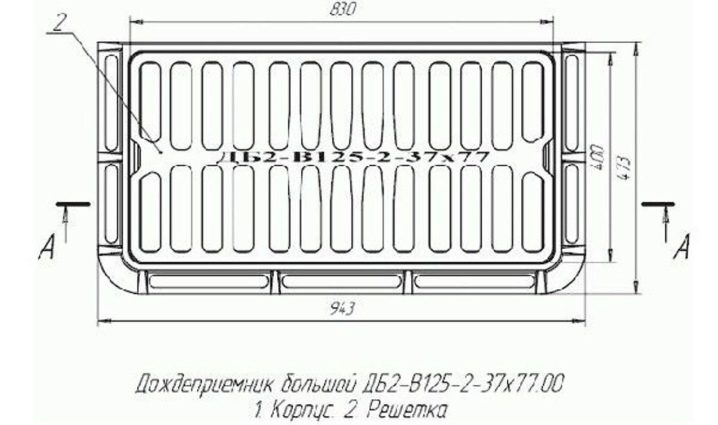

Typically, cast iron showers are made in a rectangular shape, differing in size, less often make them in the form of a square.

In the manufacture of gratings use different types of cast iron, such as gray cast iron or heavy-duty cast iron. High strength of the material is ensured by the high load class of the finished product. The load class is the main characteristic when choosing gratings for the implementation of storm sewage system projects.

Classification according to the class of loads:

- A15 (up to 1.5 tons) - designed for places with low intensity of use, for example, on footpaths, in squares and parks, in private adjacent areas of the house;

- B125 (up to 12.5 t) - use in places with low intensity of movement of vehicles, in parking lots, car parks, and so on;

- S250 (up to 25 tons) - possible to use on the territory with an average intensity of movement;

- D400 (up to 40 tonnes) is a desirable application when equipping a sewage system on major highways and highways, parking lots of trucks, gas stations, and so on;

- E600 and F900 (up to 60 tons and 90 tons, respectively) - designed for heavy loads and can be operated in ports, airports, and large industrial facilities.

How to choose?

Cast iron spillways are a good solution when installing a drainage system. They will not interfere with the passage of heavy transport, thereby ensuring the integrity of the completed flow structure. When choosing a product, it is important to follow the indicated strength indicators.

The best solution would be products with a DB marking, indicating good wear resistance under significant mechanical loads, which will ensure a long service life not only of the grille itself,but also the entire drainage design.

Recommendations for proper installation

It is recommended to install storm drains in lowland terrain points or artificially created indentations. Thanks to this nuance, all the moisture accumulated on the surface will independently go to the storm water inlet, thereby draining your chosen plot. The angle of inclination of the soil must be calculated so that all the waste water will flow into the central part of the grid. Improper construction of the storm sewage system leads to a large amount of precipitation accumulating on the surface, as a result of which the use of the entire system will be useless and unreasonable.

If the surface of the socket is dirty, it must be cleaned using a hammer or chisel.

Installation of sewers for sewage is regulated by special construction instructions. The process is carried out with accurate measurement of the depth, its width, height and strength properties. The correct choice of the location of the flow, the phased observance of all installation rules will extend the life and protect against excessive clogging. But it is also important to consider the correct location of the effluent.

The storm water inlet is placed in the prepared recess; only the frame and the cast-iron grating itself will remain on the surface. The surrounding area is gently filled with sand or poured concrete mixture. After that, everything must be properly rammed. During the installation of the cast-iron grating, it is very important not to forget about the observance of the slope during deepening.

You will learn more about how the installation of the storm grille is done by watching the following video.