"Akufleks": features of the soundproofing substrate

In the modern world, noise has become one of the types of pollution. Exceeding the level of sound load is harmful to a person’s physical and mental health, therefore, various methods of sound insulation are in demand for many types of construction and repair. This article will look at the benefits and properties of the Akuflex material for sound insulation.

What is it for?

In any housing a person is surrounded by a multitude of sounds. For example, in a private house, they can include the noises of the street, the sounds of natural phenomena, passing cars, the voices of people. In the apartment, the sounds of living people outside the adjacent walls and on the adjacent floors are added to them.

Especially the problem of noise is relevant for new buildings panel - interfloor overlappings and walls are rather thin, and neighboring residents are sometimes forced to listen even to quiet conversations outside the walls.

In total there are several types of noise that you have to fight for in order to gain comfort in your home:

- external noises - all sounds that the environment transmits: engine roar, voices of birds, dogs, screams in the yard;

- house noise is the slamming of doors and the movement of the elevator, the voice and footsteps of the neighbors, sounds from the garbage disposal;

- internal sound signals are limited to the actions of all inside it: conversations, clatter, opening and closing of doors and cabinets, sounds of pipelines, working equipment;

- indoor noise is limited to the territory of a particular room.

Hearing noise is more uncomfortable - it can be harsh, unexpected and quite loud, although the acoustic variety is more dangerous for the psyche. Living long with constant noise - loud conversations from neighbors, a nearby busy highway and other constant sounds - we do irreparable harm to our health.

In apartments, it is most often impractical and difficult to isolate ceilings, but it is possible to equip floor sound insulation - this will protect against the sounds made by the floor below. This approach is particularly relevant for apartments located above the entrance to the staircase, and for housing, located above any offices, entertainment establishments and shops. The second important factor in ensuring sound insulation is the noise in the apartment.

If there are children or large animals, the neighbors will be grateful for the lack of screams, sounds from toys and trampling.

Special features

Akuflex is produced by Acoustic Group. For two decades of its existence, this Moscow company has proved itself from the best side - sales have gone beyond the limits of the Russian market to the CIS countries and Europe. The company has a research laboratory that develops various noise insulation coatings.

"Akufleks" is one of the many varieties of special roll materials for sound insulation, based on synthetic polyester fibers. The product can adjust the level of noise insulation in accordance with the requirements for acoustic noise in modern society and GOST 23499-79.

Polyester fibers are processed using a special technology to create an elastic and durable coating.

Release form

The material is produced in rolls of convenient dimensions - the roll size is 100 cm, the length of the noise insulation coating is 15 m. Thickness is also an important parameter when flooring: at Akuflex it is 4 mm. The mass of one roll does not exceed 5 kg, which is convenient for transportation.

Specifications

Each building material determines its effectiveness according to certain quality characteristics. For noise insulation - this is primarily the surface density. At Akufleks it is 300 g / sq. The strength characteristics are determined by the tensile stress indicator — more than 750 N. The thermal conductivity is 0.036 W / ms - this is more than that of expanded polystyrene.

The main characteristics relate to reducing impact noise:

- for a laminate with a layer of 0.8 cm, the level is 20 dB;

- under the floorboard (1.5 cm thick), the indicator is less - 17 dB;

- under the coupler of sand cement, the figure reaches 120 dB.

Below are the defining advantages of the material in connection with its properties:

- The flooring becomes more durable due to the fact that Akuflex promotes air circulation and maintains normal humidity levels.

- The material does not absorb moisture, does not allow the development of microorganisms and mold.

- The composition is environmentally safe and can be used in residential areas and places of mass visits to people.

- Long service life - 25 years. At the same time sound-proof properties do not worsen over time.

- The ease of installation and dismantling, the ability to replace individual sections, which is very convenient, because it does not need to completely dismantle the cover.

- Compensates well for air gaps between the base of the floor and the finishing coating up to 3 mm high.

Application

"Akufleks" can be used to reduce the noise load as an increase in elasticity for floating screeds. It can also perform the functions of additional installation between coatings in buildings and other types of noise insulation. A plus to use is possibility of laying both under the screed and directly under the finishing coating - laminate, linoleum or parquet.

Installation Tips

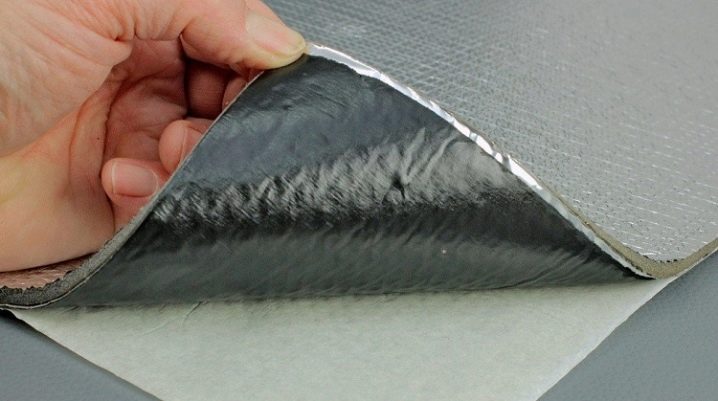

To use the “Akuflek Super” material, follow the recommendations described below.

- First of all, you should prepare the base of the floor. To do this, it is necessary to thoroughly sweep - this will allow to exclude particles of construction debris between the layers of the base and the canvas of the material.

- Then the material is cut to the appropriate size. This should be done so that the entire required floor area is covered with material placed on the walls and columns, if any, above the level of the screed - this approach is necessary to avoid contact between the screed and the structural features of the building.

- You need to ensure that the bitumen component of the material was on top, and the edges are overlapped. If you pay attention to the material, then each roll has one end of a free layer of bitumen 100 mm wide.

- The material should be mounted on the wall to avoid shears during screed planning. For this you can use a building dryer or self-adhesive bitumen tape. Joints will be formed between the canvases - they must also be glued using a building dryer.

- In the places of projections - doorways, pipes, corners and other elements of the room - it is necessary to provide a bypass of these elements.

- After laying the described material should perform cement-sand screed - its thickness should be 60 mm.

The device floors with sound insulation

From the above it follows that the installation of noise insulation can be done in two ways, which will be discussed below.

Device for cement screed

Step by step instructions are as follows:

- First of all, it is necessary to prepare the base: clean it from debris and dust, repair all cracks with repair mortar. For these purposes, you can use a cement mixture, pre-treating the surface of the grooves with a primer, as well as seal up all the technological holes and places of pipe laying.

- After that, the bottom of the walls is glued with a damper tape to compensate for the loads on the flooring.

- An important step is the installation of waterproofing, which will protect the lower floors from moisture and moisture from the outside to the base layers. For these purposes can be used dense plastic film.

- Then fit a layer of noise insulation. Necessary segments are made with sharp scissors.

- After that, you need to lay another layer of film to protect the soundproof material.Between themselves, it can be sealed with construction tape, not forgetting to process the plots entering the wall above the level of the intended screed.

- Then it is necessary to install the beacons on which the next layer will be carried out - usually for these purposes profile metal guides are installed on the cement mortar.

The next stage of work is the execution of the screed:

- Wet screed done by pouring cement mix to a certain level. Most often used cement M300. In thick layers of the screed can use a reinforcing mesh, which is installed at a level not lower than 2 cm from noise insulation. Rule level the surface.

- Then it is necessary to wait for the solution to fully harden. As a rule, it takes from ordinary cement up to 28 days. After that a layer of self-leveling floor can be applied for complete leveling. The surface in front of its device must be carefully primed. The remains of the damper tape are cut strictly according to the level of the tie.

- Thereafter the edge of the tape is treated with an anti-vibration sealant. It is necessary to lay a finishing covering on the technology corresponding for it,using all recommended tools and fixtures.

- A semi-dry screed is somewhat easier to lay because of its consistency.: it contains less water. First lay out the draft layer 20 mm thick, then form a reinforcing mesh and put a second layer. After that, it is leveled and allowed to dry for some time. The screed dries faster than the wet option, but the risk of defects increases significantly - the surface may not be too even. However, if desired, it can be sanded using the recommended tool. Then the layer is primed, the floor is leveled with a special mixture and excess damping tape is removed.

- As a dry screed often used claydite with an average fraction. According to the beacons, this material is leveled with a rule or with a wooden lath, GVL sheets are installed on top.

- It is accepted to begin laying work from the entrance to the room. To do this, fasten the cloths with each other with special adhesives and mastics, then fix them with hardware. The distance between fasteners can reach 0.3 m. On the surface should not stick out parts of hardware.All joints and visible defects from self-tapping screws need to be puttied. After that lay the finish coating - parquet or laminate.

Laying under the finish coating

Styling technology:

- The base is dedusted, defects are sealed and a damper tape is installed.

- Then requires the laying of a layer of waterproofing.

- After that, the markup is performed, and beacons are set.

- There is equipment screed.

- The surface must be sanded if the screed is wet or semi-dry. After that, construction waste and dust particles are removed.

- Then fit insulation. Pre-professionals advise to lay a layer of plywood bonded to each other on the subfloor.

- The sheets "Akufleks" need to be stapled together with building tape. On the walls to bring this material in such a way that then he was disguised with baseboards.

- After all the manipulations done, you can install a finishing coating.

Reviews

"Akufleks" is used by both professionals and homemade DIY repair people. Both those and others note the low cost of material. Customers emphasize the ease of working with the material, while even an unprepared master will be able to easily perform the process of sound insulation.Consumers emphasize good sound insulation properties and reduced impact noise.

The material is available on a price basis and is presented in many building hypermarkets and online stores.

"Akufleks" and analogues: comparison

- Isoplaat - it is an eco-friendly material from natural fibers of needles. In comparison with the product described above, its layer is twice as thick, and the level of noise reduction is the same. But "Isoplat" absorbs moisture and is exposed to fungi and mold.

- Tuplex It is made of foam particles, which are located between the sheets of polyethylene. The advantage of this material are high waterproofing properties and resistance to microorganism damage. At the same time, the cost is quite high, and the noise absorption index is small - it reaches less than 8 dB.

- Izoshum used for heat preservation and waterproofing. The synthetic base does not respond to moisture effects and does not allow mold to develop, maintaining durability, but the noise reduction level is less than that of Akuflex (about 15 dB).

- Izolon - cellular foam material, well insulating heat and steam.Noise reduces at 35 dB, but unlike the material in question, it does not withstand high loads.

- Cork backing used as heat and sound insulation. It does not absorb water, but due to its natural origin it is exposed to mold. The material is unstable to loads, fragile and has a very high cost.

How to make a budget soundproofing in the apartment with your own hands, you can find out by watching the video below.