Sound insulation "Shumanet-100": types and application

The atmosphere of large cities and the construction of apartment buildings pose to manufacturers of finishing materials the task of producing innovative products that reduce the ingress of noise, cold and moisture into a room. Today, the buyer can see a new high-performance building material for insulation “Schumanet-100” on the shelves of building stores. The elastic substrate has unique properties and technical characteristics to protect any room from the negative influence of the environment.

Special features

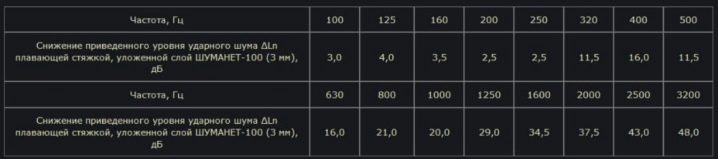

"Schumanet-100" - an innovative soundproofing building material that allows to reduce the frequency and amplitude of impact noise.Production is carried out in accordance with the requirements of SNiP 23 03 2003 for class B facilities. The Shumanet trademark is certified in accordance with established hygienic and acoustic standards.

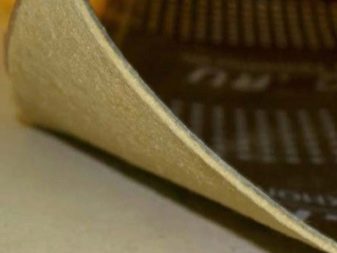

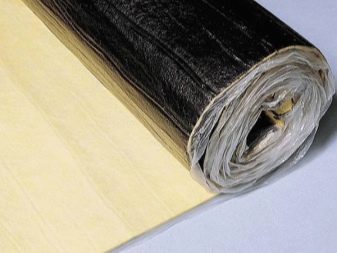

The coating consists of several layers of fiberglass with a polymer surface. Sheet thickness in a roll - no more than 3 mm. The width of the roll is 1 m, weight - 20 kg, and length - 15 m.

Building stores offer two types of rolls:

- without core;

- with core.

Distinctive features of insulating material from mineral wool:

- made of basalt wool;

- binding material - synthetic acryl;

- lack of phenolic components;

- used on complex objects;

- has a high raw material cost.

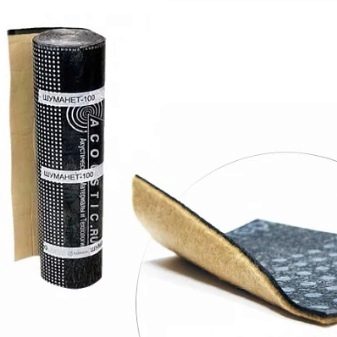

The main distinguishing feature of the material is high acoustic properties with a small thickness and a long period of operation. The bitumen coating of the bottom side makes it possible to mount it without the additional use of separating materials. The bituminous coating also gives the material a vapor barrier and waterproofing properties,and fiberglass provides air movement and evaporation of moisture.

Advantages and disadvantages

Soundproof glass fiber has the following advantages:

- durability;

- reduction of impact noise;

- small thickness;

- unique structure;

- high quality;

- high waterproofing and sound insulation performance;

- ease and speed of work;

- mobility;

- wear resistance;

- no shrinkage;

- resistance to high temperatures;

- convenient packaging;

- sound and noise insulation;

- possibility of laying on a concrete base;

- high acoustic performance;

- resistance to chemicals;

- the possibility of use in rooms with high humidity;

- possibility of application for all types of reinforced concrete surfaces;

- environmental Safety.

Material Disadvantages:

- suitable only for self-leveling floors;

- storage in dry rooms protected from sunlight and moisture penetration;

- installation only at temperatures above 0 degrees;

- complicated cutting process.

Species

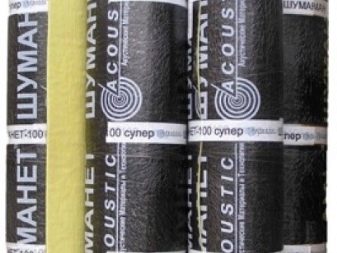

The manufacturer produces several types of products brand "Schumanet" with different properties and characteristics.

- BM - base material with high insulation performance. It is produced in accordance with established norms and standards, has a low price, is used to cover walls.

- Sc - has an additional fiberglass coating that holds the fibers. Available at a price applied for sound insulation of walls and ceilings of industrial premises.

- ECO - New non-combustible and environmentally friendly material. It consists of acrylic and staple fibers, has high acoustic performance.

- Super - modern sound-proof material for rooms with a level of comfort class A. It has a thickness of less than 5 mm, suitable for repair of offices and rooms with a small area, used for sound insulation of professional studios.

- Combo - a unique development of manufacturers, consisting of fiberglass impregnated with concrete coated with polymer felt. It is used for sound insulation and waterproofing.

- 100 C - advanced building material for luxury housing.

- Hydro - demanded type of building material. It is used in rooms of different types, has waterproofing properties,contains modifying additives that increase the elasticity of the canvas.

Joints are joined by heating the edge of the web.

Before purchasing insulation material, it is necessary to study all types of technical specifications or consult a building store employee.

Wrong choice may affect the result of work.

Application

Oscillation of sound has a unique feature of wide distribution. Mute it is quite difficult. Vibrational vibrations penetrate through thick walls and various structural elements. The relief surface of the building material “Shumanet” picks up sound vibrations and reduces their frequency.

The universal properties of the material and high quality allow it to be used in buildings of various types and purposes. A huge range of products, represented by different types, makes it possible to cover not only the floor and walls, but also the ceiling, as well as partitions. The technical characteristics and properties of the material make it possible to apply it in all acoustic structures, to veneer plywood and drywall, to create acoustic perforated screens and suspended ceilings.

The environmental safety of Shumanet Eco products allows for soundproofing work in children's institutions and recreation areas. The main difference of this type of material is the use in the production of staple fiber impregnated with a water-repellent solution.

Sound insulation material must be laid under a screed of cement and sand. Concrete slabs are covered with a web of bitumen side down. For reliable fixation of the web, the joints must be glued together with building adhesive tape. The thickness of the reinforced screed must be at least 6 cm.

Particular attention should be paid to the process of mounting plates on the ceiling. Soundproofing the ceiling involves reducing the frequency of sound vibrations from above and reducing the acoustic noise coming out of the room.

It should be noted that the installation of soundproof structures can reduce the height of the walls up to 15 cm.

Technology laying insulation material - an important stage of construction work. Installation must be carried out in accordance with the requirements specified in the instructions.

Works on the installation of "Schumanet" are carried out in several stages:

- installation of profiles that reduce sound vibration;

- laying vibration-proof material;

- installation of the second level of profiles;

- fixing the second layer of insulating canvas;

- fastening of gypsum fiber sheets;

- sealing joints with special solutions;

- plastering and painting.

Useful recommendations

For high-quality installation, novice craftsmen need to learn the rules and standards of work. It is necessary not only to know how to lay sheets.

It is also necessary to take into account the recommendations of professional builders concerning some nuances:

- before unwinding the roll, remove the fixing tape;

- laying rolls overlapped;

- to ensure the circulation of moisture, it is necessary to leave gaps up to 1 cm;

- cutting should be done with a construction knife or scissors for carpet coverings;

- when installing insulating plates, it is necessary to eliminate hard contact between the coupler and the structures;

- before unwinding the roll, it must be left in the repair area for 24 hours;

- construction work is possible at a temperature not lower than 15 degrees and air humidity not more than 65 percent;

- installation of the coating should be carried out on a smooth, clean and flat work surface;

- screed must be reinforced with metal mesh;

- the surface of the mixture can be leveled at the building level;

- you need to carefully cut the canvas in the places of doorways and in the corners, to place the material on the walls and columns;

- cutting material must be carried out according to the planned size;

- dry leveling mortars are used to level the base;

- it is worth using only high-quality building materials;

- laying floorboard on "Shumanet" should be made in accordance with technological standards and norms;

- when carrying out construction works, it is necessary to follow safety regulations and apply personal protective equipment.

Customer reviews speak about the high quality of the products of the Shumanet brand. Professional builders recommend using it in rooms with a high requirement for the level of waterproofing and sound insulation. A wide range of products allows you to choose the type of material that is suitable for each case in accordance with the technical parameters of the room.

You can find out how to make a budget soundproofing of the walls in the apartment with your own hands, by watching the video below.