Aeroc aerated concrete: characteristics and instructions for use

For centuries, construction was carried out only from wood, bricks and natural stone. The emergence of concrete, including aerated concrete has become a real era of construction activity. But not all brands of this product are equally valuable.

Special features

For more than three quarters of a century, aerated concrete has been actively used in building practice.

It finds application in the following areas:

- production of bearing and secondary walls;

- creation of auxiliary insulation;

- formation of reinforced slabs for overlapping structures.

Using aerated concrete blocks is useful because they have the following features:

- exceptionally resistant to ignition;

- differ in the first-class heat protection;

- allow you to live equally comfortable in the winter and in the warm season;

- they serve for a very long time and are distinguished by a relatively low price (in comparison with products of similar characteristics).

Why choose Aeroc?

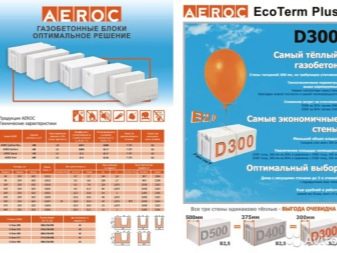

In its industry, Aeroc has been famous for a long time and uses only first-class raw materials. A team of qualified engineers and developers take special measures so that they can apply the manufactured products in any climate. Additional processing of blocks, if the need for it arises during construction, is carried out easily and simply. The range is quite diverse in size, color and geometric shape. The Aeroc gas block always has a length of 60 cm, while the height varies from 20 to 25 cm. The thickness of the unit structure, which can be 7.5–40 cm, is even more widespread

The traditional block format is fully consistent with the standard geometry of aerated concrete products, now produced by many other companies. The Elements line is optimized for partitioning in its configuration, and the EcoTerm feature is a “tongue and groove” connection.The fee for the supplied aerated concrete blocks is at least 3000 rubles per 1 cu. m. It is impossible to say more precisely, because this parameter is influenced by the seasonality of work, the distance of transportation, the category of material purchased, and its quantity. Qualified specialists of Aeroc are ready at any moment to give an answer on all these points. Usually, the larger the batch ordered, the cheaper the individual concrete block. In this case, tariffs are drawn up completely openly, customers can always control their content.

How to use?

Positive reviews are given only by those consumers who strictly and strictly follow the Aeroc work technology guidelines. Invalid installation with the use of even the highest quality cement. There is a clear indication - to use branded specialized glue.

This solution has the following advantages:

- preventing the formation of input channels for cold;

- exceptional resistance to ingress of water;

- stability with strong cooling;

- hardening within 120 minutes (you can correct immediately found slips);

- excellent water vapor permeability.

Glue gives decent results strictly under certain conditions. To use it, the air must have a temperature of from +20 to +22 degrees with a relative humidity of 55%. When you have to build or repair a building at a low temperature, it is advisable to take a specialized brand solution instead of glue. Subject to the regulatory requirements, storage of the composition is possible for 12 months. All products of the company are distinguished by an excellent proportion of strength and gravity, which makes it possible to impart to structures a high load capacity with little thermal conductivity.

Range

It’s rather difficult to talk about the technical characteristics and dimensions of Aeroc aerated concrete blocks, about the features of their use in general. It would be more correct to analyze their specifics separately. Thus, the tongue-and-groove variety of wall structures ensures quick and accurate installation of the blocks. The verified structure of the faces at the ends makes it possible not to fill the vertical gaps of the elements. As a result, the consumption of the adhesive mixture is significantly reduced. An additional advantage of this modification is the presence of comfortable pockets for hand carrying.

Important! Any original product supplied under the Aeroc brand is sold only with the technical passport from the company. This circumstance allows virtually guaranteed to exclude the purchase of a fake.

Any design company Aeroc undergoes professional processing in an autoclave. Thanks to her, the main characteristics of a natural stone are stable, enlarged several times. Aeroc company closely monitors compliance with technological requirements and buys only first-class raw materials. The variation of strength is achieved by changing the amount of the main constituent substances. An important role is also played by the control of expansion of aerated concrete to certain dimensions, which is organized in accordance with national standards. The use of shale ash, which spoils the environmental parameters of building materials, is excluded. As the company itself declares, the laying of the blocks it has issued is extremely difficult to spoil or cover with a poor finish.

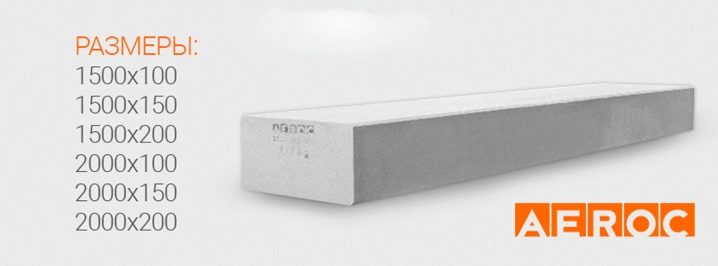

Jumpers brand Aeroc can have different linear parameters, but in any case they provide accelerated closure of openings inside partitions and in walls of branded blocks.When the hole has a width of less than 120 cm, jumpers with a length of 150 cm are used. For openings 120–170 cm wide, jumpers of a larger format — 2 m — are intended. The weight of these structures is limited to 7–15 kg, so you can even install them alone. If you use the details of the version of EcoTerm D400, you will be able to create the warmest construction (compared to the offers of competing firms).

The maximum permissible (distributed over the entire surface) mechanical load on the jumpers is 200 kgf per 1 running meter. m

Therefore, products of this kind are acceptable for the following purposes:

- partitions of any type;

- self-supporting wall of various formats;

- load-bearing walls, which are supported by monolithic floors.

Important: if you plan to use Aeroc aerated concrete bridges for other situations, you will have to make a calculation to evaluate their suitability.

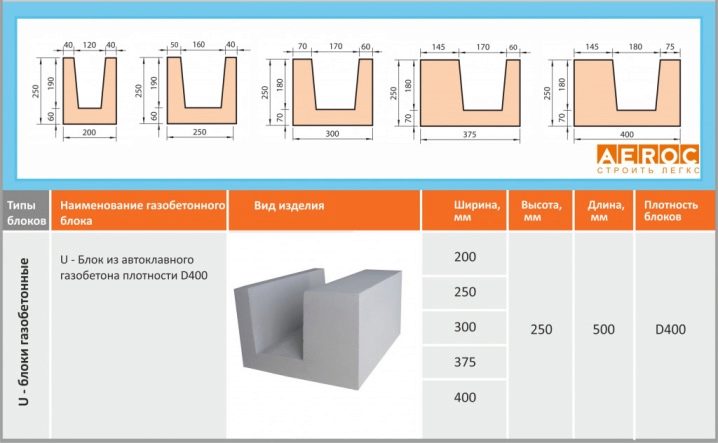

Aerated concrete blocks of the U-Aeroc range are designed to become part of monolithic stiffness belts. And also they will find application in the composition of the supports under the ceiling, beams, rafters, mauerlatov. The use of jumpers under windows and doors is allowed. The size of the blocks of group U is equal to the dimensions of those parts that are intended for ordinary masonry.Their length is exactly 50 cm.

When you want to apply the most durable and stable type of construction, you should buy aerated concrete blocks Aeroc Hard 600. The strength of such structures confirmed by tests is 3.5 MPa, while the thermal conductivity of a dry material does not exceed 0.14 W per 1 m² per second. The frost resistance established by the same tests corresponds to category F100. Blocks Aeroc Classic (D500) is another development with the highest characteristics that anyone can buy. Any modification of aerated concrete blocks of Aeroc company immediately occupies one of the leading positions in the market. The company makes every effort to obtain first-class structural elements.

With the help of EcoTerm Plus modification products, it is quite possible to build a stone wall with a thickness of 0.2 to 0.3 m, which fully complies with the latest thermal protection standards. The products have already been tested on high-rise buildings and have been manufactured since 2009. Comparison of Aeroc products with materials with similar properties shows that all analogues are inferior either in terms of their carrying capacity or in terms of thermal protection. The bearing characteristics of branded products are sufficient for arranging monolithic reinforced concrete floors.A 20–30 cm thick wall is not accidentally named, since it is this option that is sufficient to stop the effects of cold in almost the entire European part of Russia.

The theoretically calculated mechanical resistance of the masonry to compression is 800 kPa. This is equivalent to an effect of 15 tons per 1 running meter. EcoTerm Plus due to these properties is sufficient for the construction of buildings with a height of 1.5-2 floors with a monolithic type of floors under a flat roof. If you use a lighter floor and roof increased steepness, you can make the third floor. Compliance with the sanitary and hygienic standards of heat losses (for St. Petersburg and the surrounding area) is guaranteed, with a masonry layer of 17–25 cm.

For information on how Aeroc aerated concrete is used, see below in the video.