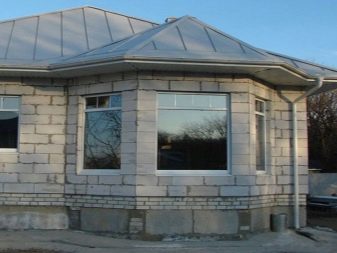

Aerated concrete blocks: types and scope

The modern building materials market pleases consumers with its rich variety. Relatively recently, aerated concrete was used in private construction. Blocks made from such raw materials have many positive characteristics for which many buyers choose them. Today we will take a closer look at this practical and popular material, and also find out what types of aerated concrete blocks can be found on the construction market.

Special features

Modern consumers face a huge selection of building materials for every budget. Particularly popular recently are block products, which are distinguished by flexibility in work. Moreover, from such elements it is possible to quickly build a full-fledged house with one or two floors.

Aerated concrete makes reliable and durable housing, which is quite possible to build with your own hands, without resorting to the services of specialists.

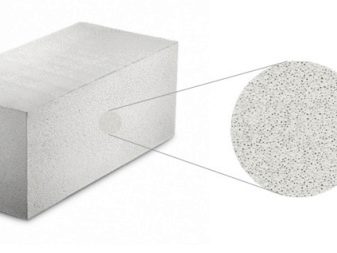

Under aerated concrete is meant a stone of artificial origin, which is made of concrete with a cellular structure. Many consumers believe that aerated concrete blocks are an analogy of foam blocks. In fact, this opinion is not true. Gas-blocks are completely different materials. In them, voids are formed during the chemical reactions that occur as the concrete hardens. The foam blocks acquire a cellular structure due to the foam component added to the solution.

There are several varieties of aerated concrete blocks. You can choose the right products for a variety of purposes. It is worth noting here that not only do they build country houses or small private constructions from gas-blocks.This material can be safely attributed to the universal, because it also makes neat gazebos, original fences, and even such non-standard items for construction materials as garden beds.

Advantages and disadvantages

Houses and cottages built of aerated concrete, today are found with an enviable frequency. The prevalence of such erections is due to the fact that aerocrete have quite a few positive qualities for which they are chosen by buyers.

Let's take a look at the advantages of this material:

- One of the main advantages of aerated concrete is its optimum density. This parameter can be from 400 to 1200 kg / m3. If you use high-quality material with a low specific gravity in construction, then it will take a little time to build this or that object.

- These materials are moisture resistant. Even if they are located in conditions of high humidity, their indicators from this change slightly.

- Aerated concrete has another significant advantage, which is especially valuable for building materials - it is fire safety. Gas units are not flammable materials.Moreover, they do not sustain combustion.

- These materials are not afraid of low temperatures. Due to this actual quality for our country, it is possible to refer to such blocks even if construction is planned to be carried out in harsh climatic conditions.

- Aerated concrete is an unpretentious material that does not have to be regularly sprayed with antiseptic or any other protective compounds. On such blocks does not appear mold or rot. In addition, they are completely uninteresting to insects and rodents. Not all building materials can boast the same characteristics.

- If you made a high-quality laying of aerated concrete blocks, they will not create cold “bridges” at the joints, so the dwelling will not be able to leave the heat.

- Aerated concrete is a durable material. Constructions made of it can last more than a century.

- These types of blocks are environmentally friendly. There are no hazardous and harmful compounds in their composition, so there is no need to worry about the health of the household. Experts say that only natural wood can compete with aerated concrete in environmental friendliness.

- Aerated concrete has noise insulation properties.Thanks to them, annoying noise from the street is usually not heard in gas-block dwellings.

- Aerated concrete is also characterized by excellent thermal characteristics (no worse than that of a brick). Houses made of this material, in some cases, you can not insulate at all.

- Not to mention that aerated concrete is a very durable and sturdy material. If you provide him with high-quality reinforcement, then you can safely proceed to the construction of buildings with several floors.

- Aerated concrete blocks are “obedient” materials. If necessary, they can be cut or give them a non-standard form, as evidenced by many reviews of masters.

- This product is also popular because of its affordable price.

- In the production of such blocks is spent very small amount of cement.

- Aerated concrete blocks have a very modest weight, so moving them from place to place is not difficult, as well as carry out various construction works.

- As mentioned earlier, aerated concrete is a multi-tasking material from which it is not only possible to build houses, but also other useful objects such as fireplaces and gazebos.

- Dwellings or outbuildings of aerated concrete are built very quickly, since such blocks are large in size with light weight.

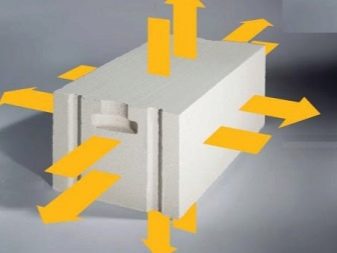

- Aerated concrete is distinguished by good characteristics of steam and air permeability. Thanks to these features, natural air circulation is always present in the living rooms, which forms the most comfortable microclimate of the dwelling.

- Aerated concrete blocks are affordable materials that are manufactured using high-tech equipment. These materials undergo strict quality control.

Aerated concrete blocks are not ideal material. It has its minuses.

Consider them:

- The main disadvantage of aerated concrete is its high hygroscopicity.

- For erections from this material it is necessary to prepare ideal foundation structures. The slightest mistake can lead to the fact that cracks will appear on the block walls, not only on the masonry lines, but also on the blocks themselves.

- Despite the fact that aerated concrete blocks are responsible for the formation of the optimum moisture level, over time, moisture begins to accumulate in their structure. As a result, this leads to their destruction.

- As mentioned earlier, the cost of such units is quite affordable, but the same foam blocks are still cheaper.

- These materials have thermal insulation properties, but they are not high enough. In this issue, aerocrete ahead of many materials, such as foam concrete.

- For these materials you need to buy special fasteners.

- Aerated concrete can be trimmed only with special materials designed specifically for this type of block.

- You cannot build buildings with more than 5 floors from block aerated concrete.

- It is necessary to transport aerated concrete blocks carefully so as not to damage them - the porous structure makes such materials more fragile.

Production technology

Aerated concrete blocks are made as follows:

- First, a mixture is prepared consisting of components such as Portland cement, silica sand, water, lime and a special blowing agent.

- The solution is placed in a special form. It is further swelling of the mixture. As a result of this process, voids are formed in the concrete structure.

- When the block freezes, it is taken out of the mold and cut according to the correct dimensional parameters.

So get aerated concrete blocks of a certain shape.

There are two main methods of manufacturing these materials:

- autoclave;

- non-autoclaved.

In order for aerated concrete to acquire high strength characteristics, the blocks are treated with water vapor, and then placed until they are completely dried in the chambers that are in a special autoclave. So get aerated concrete blocks of autoclave type. Having undergone a similar treatment, they acquire more stable strength parameters.

Non-autoclaved aerated concrete costs less than an autoclave version. Such material is made by moistening and drying the material in natural conditions.

It should be noted that the formation of aerated concrete blocks from the frozen mixture is considered the main difference of aerated concrete from the well-known foam concrete. This fact provokes violent disputes among buyers, since the pores of this method of manufacturing still remain open.

Species

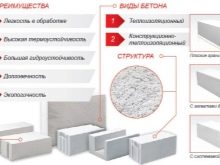

Nowadays several types of aerated concrete blocks are produced. They differ from each other in density and strength characteristics.

Let's get acquainted with the list of the most common and frequently encountered varieties of such building materials:

- D350. Blocks with such markings are less common. This fact is explained by the fact that these materials are quite fragile. It is recommended to install them only in the role of sealing structures. Their strength level is only 0.7-1.0 MPa.

- D400. Aerated concrete blocks with similar markings are durable and reliable. The strength parameters of these materials are usually 1-1.5 MPa. It is allowed to use these blocks both as insulating bases and as openings in the conditions of buildings with several floors.

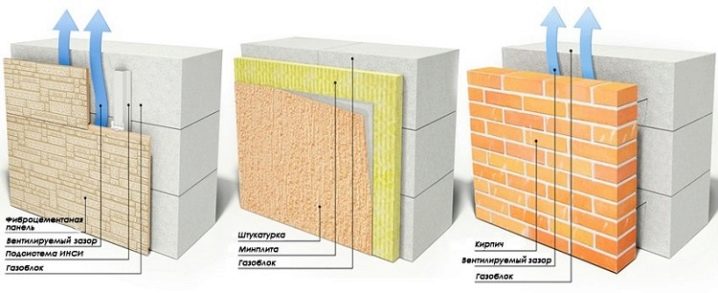

- D600. Thus high-strength varieties of aerated concrete blocks are marked. Their strength parameters are 2.4-2.5 MPa. Due to its performance, such aerated concrete is often used in the design of buildings with ventilated facades.

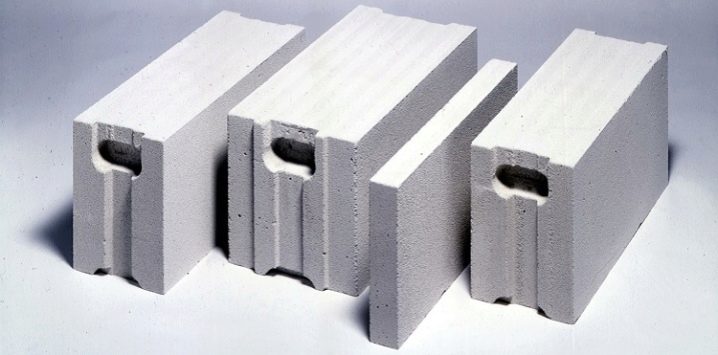

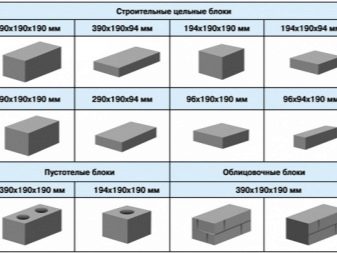

Aerated concrete blocks can have different shapes, for example:

- rectangular - these specimens are used in the construction of bearing and partition walls;

- T-shaped - these blocks are used for the construction of floors;

- U-shaped - such materials are usually used in the design of window and door openings;

- arc-like.

In addition, aerated concrete block materials are:

- constructional;

- heat insulating;

- construction and heat insulation;

- universal;

- special.

Specifications

Blocks of aerated concrete are produced with various dimensions:

- 600x300x200;

- 600x300x300;

- 400x300x300;

- 600x400x300;

- 400x400x300.

Knowing the dimensional parameters of these materials, you can easily calculate in what quantity they will be needed to carry out these or other construction works.

As for the density parameters, everything depends on the specific brand of blocks:

- construction options with marking D1000-D1200 are distinguished by a density of 1000-1200 kg / 1 m3;

- construction and heat insulating parts of the D600-D900 brand are manufactured with a density of 500-900 kg / m3;

- thermal insulation materials of the brand D300-D500 have a density parameter from 300 to 500 kg / m3.

It should be noted that blocks of different density can be distinguished by the form.

Details of aerated concrete are made with different strength classes. This indicator shows how much load can withstand this material. So, for example, the block of strength class B2.5 can be used in the construction of strong load-bearing walls, the height of which can reach 20 m.

There are also materials that have such classes, indicating their strength:

- B1.5;

- B2.0;

- B2.5;

- B3.5.

Aerated concrete blocks can have a different coefficient of thermal conductivity.

This indicator is indicated as follows:

- 0,096;

- 0,12;

- 0,14;

- 0,17.

These parameters indicate the ability of a warmer space to transfer its heat to cold rooms. The higher the coefficient, the more tangible is the thermal efficiency. To determine the material of a suitable coefficient for your home, you should consider the level of humidity.

Another important parameter of aerated concrete blocks is their frost resistance. It is measured in cycles. For such building materials, symbols from 25 to 100 are used. For comparison, a brick can be taken, which can have no more than 50 frost resistance cycles.

When choosing such a material, it is important to take into account its shrinkage during drying. It should be no more than 0.5 m / m. If this parameter exceeds the specified mark, then you risk getting noticeable shrinkage cracks on the gas concrete walls. For this reason, experts strongly recommend buying materials that comply with GOST.

As for the weight of m3 aerated concrete blocks, everything depends on their direct marking:

- D300 - 300 kg;

- D400 - 400 kg;

- D500 - 500 kg;

- D600 - 600 kg;

- D700 - 700 kg;

- D800 - 800 g;

- D1000 - 1000 kg;

- D1100 - 1,100 kg;

- D100 - 1200 kg.

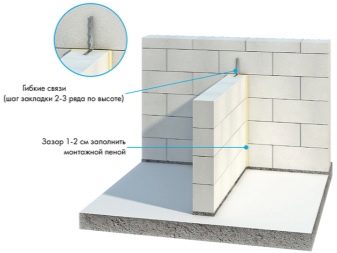

How to avoid cracks?

As mentioned earlier, aerated concrete blocks are materials subject to cracking. These defects can occur for various reasons, but most often the reason is a poorly executed foundation.

To avoid such problems, you should:

- to equip the foundation plate or tape type, strictly adhering to the appropriate technology;

- to carry out the laying, not forgetting about the arrangement of the reinforced belt;

- create ring straps.

If the block still cracks, then do not be afraid. This material is the ability to restore. To do this, usually use a quality mixture based on gypsum.

Where can I use?

Aerated concrete is a practical and sought-after material. It can be used for various purposes.

Not only private residential buildings are being built from this material, but also household structures. Also, aerated concrete is suitable for the construction of industrial and administrative buildings.However, please note that for buildings with a large number of floors, it is unlikely to fit.

Due to its operational characteristics, aerated concrete blocks can be used in the construction of houses, even in harsh climates. In addition, this building material is permissible to use as a construction, sound insulation and heat-insulating bases. It is used in the construction of different walls. Reliable and strong external and internal walls are obtained from such types of blocks - they can be single, load-bearing, double or combined.

Blocks based on aerated concrete are great for installing dividing and fire partition walls. These elements can be filled with steel or concrete frames.

Another of the areas of application of aerated concrete blocks is the restructuring, as well as the restoration of old structures. For the restoration of buildings that have been in use for many years, the gas-block is suitable because of its low weight.

This building material is often used with the purpose of soundproofing or insulating a home. It is suitable for warming both low-rise and high-rise buildings.To insulate the building, usually use special types of aerated concrete, which have small dimensions.

Aerated concrete is used in the arrangement of stair steps, floor slabs and lintels.

Recently, aerated concrete with a cellular structure has often become used in other areas. In this case we are talking about the construction of the walls of the basement or foundations. However, to justify the use of aerated concrete blocks usually require additional testing, aimed at identifying the reliability and durability of materials.

How to calculate the quantity?

Before you go shopping for aerated concrete blocks, you need to calculate how much you need them. This is necessary in order not to buy too much excess material or to purchase them in insufficient quantity.

To carry out the required calculations, use the following formula: (LхН-Sпр) х1.05хВ = V, in which:

- L is a common parameter for the length of gas-block walls;

- H is the average height of the walls of aerated concrete;

- Spr - designation of the total area of door and window openings;

- 1.05 is a factor with a margin of 5% for trimming;

- B is the designation of the thickness parameter of the gas blocks;

- V is the volume of the required amount of aerated concrete.

If you rely on the above formula, you can create a clear table for calculating the number of blocks in a cube.

Sizes of gas blocks, mm | pieces in a cube |

600×200×300 | 27,8 |

600×250×50 | 133,3 |

600×250×75 | 88,9 |

600×250×100 | 66,7 |

600×250×150 | 44,4 |

600×250×200 | 33,3 |

600×250×250 | 26,7 |

600×250×300 | 22,2 |

600×250×375 | 17,8 |

600×250×400 | 16,7 |

600×250×500 | 13,3 |

But be sure to bear in mind that such calculations give only approximate results, which are more of a recommendatory nature. Today, on the websites of various manufacturers, you can find convenient online calculators with which you can easily and quickly make all the required calculations.

How to put?

If it has been at least a month after the foundation has been poured, you should do it by waterproofing it. To conduct these works is very important, because the concrete does not tolerate contact with dampness and moisture.

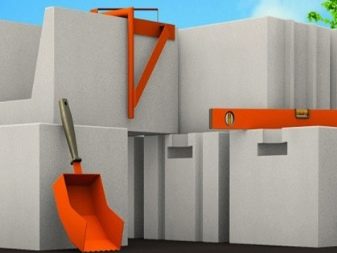

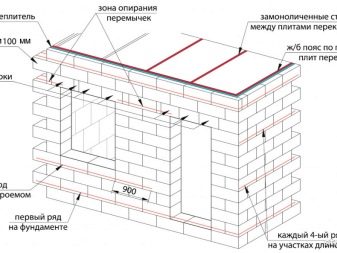

The starting row of blocks must be laid out, using concrete mix as a binder. Keep in mind that the first laid parts will act as the basis for the future wall, so the materials should be installed as exactly and correctly as possible.

If during the installation of the first row you made mistakes, then over time, this blocking may crack due to internal tension.

Leveling the starting masonry is necessary with the use of a special building level and a rubber hammer. Do not forget that the first block row must be reinforced. Subsequently, the installation of the rod should be done every 4 rows.

All the following rows must be laid using a special adhesive solution. Thanks to this technique, the seams are obtained at the maximum thin, due to which the finished wall will have more efficient thermal properties.

In order for the wall to end up as smooth and accurate as possible, it is necessary to use such a detail as a cord-wharf. After installation, the upper part of all rows must be treated with a special hand float (or other similar tool) in order to provide materials with higher adhesion properties.

The laying of aerated concrete blocks is completed with the arrangement of a reinforced belt. For this, in the upper part, a formwork assembled from boards is fixed on the finished wall. The reinforcement is placed into it.

After that, concrete form should be poured into the formwork. Its proportions should be: sand - 3 parts, cement - 1. Since the quality of thermal conductivity of concrete are higher,rather than in concrete blocks, this belt can not only strengthen the walls, but also cause thermal losses in the interior of the premises. Because of this, it will need to be further warmed.

Currently, many manufacturers selling aerated concrete blocks supply the market with ready-made rigid belts. They are elongated blocks with a porous structure and a groove in the middle part, into which it is necessary to pour concrete solution.

We must not forget about the reinforcement of block masonry. For carrying out these works you will need not only adhesive composition, but also bars of reinforcement and a wall chaser (you will need it when working with window and door openings of the building).

Having completed the laying of aerated concrete blocks, they should be trimmed. To do this, use a plane or a special grater.

Tips and tricks

When laying aerated concrete blocks, it is necessary to take into account that the parameter of the length of horizontal joints should be approximately 2-8 mm. If we are talking about vertical seams, then their size should not exceed the mark of 3 mm. If excess solution appeared from the seams, then they do not need to be rubbed - these elements must be removed with a trowel.

Carrying out the installation of aerated concrete blocks with your own hands, it is recommended to use homemade scaffolding. It will be much easier to work with them. Do not forget that the quality of the entire wall will depend on the installation of the starting block row. That is why it is so important to use the building level at the very beginning. If you notice certain inaccuracies, they should be eliminated as soon as possible, and only then proceed to the installation of the next row.

If you work with aerated concrete blocks, then you should use only special fasteners. Simple screws for such structures simply do not fit - they will not be securely and firmly held in blocks.

Note that if there are parts such as gripping handles in the blocks, then when they are installed, the flow rate of the adhesive composition may increase significantly. The reason for this is that the technology of laying aerated concrete provides for the filling of absolutely all cavities in the course of work.

Carefully transport aerated concrete blocks so as not to damage their surface. It is recommended to cover this material with plastic wrap, which will protect them from negative external factors.If in the course of laying window or door openings you did not manage to get into the length of the whole aerated concrete block, you can take a hacksaw or saw and cut off an extra piece of part. This work does not take much time and effort, since aerated concrete is a malleable material.

If you are going to use aerated concrete for the construction of a private house, then you need to take the most responsible attitude to the choice of a reliable and strong foundation. This is due to the fact that this material does not sustain the movements of the base. Because of this, the type of foundation should be chosen based on the characteristics of the soil and the characteristics of the gas block itself.

Experts do not advise laying aerated concrete blocks, starting from two angles towards each other. As a result of such actions, it will be difficult for you to bandage the rows and adjust the finishing element to the required size. Before you buy aerated concrete blocks, you need to carefully inspect them. The materials should not be the slightest damage, chips or cracks. If you notice any, then the purchase is better to refuse.

Do not look for too cheap stuff. Unexpectedly low prices may indicate poor quality blocks.

In the next video you will find a masonry of aerated concrete blocks.