How to make partitions of aerated concrete blocks?

During repairs, zoning is often required. Partitions made of aerated concrete are usually used for this purpose. This material weighs less than a brick, but is very durable, so it can be the basis for mounted structures. Installation, as a rule, is quick and smooth.

General rules

Partitions of aerated concrete blocks have several important requirements in the application. First, they can not be carriers - slabs or reinforced concrete monolith should still be based on the main walls. Secondly, the partitions themselves must rest on the foundation or the lower floor. Third, they should dock with at least one adjacent wall.

In addition, aerated concrete blocks must be able to withstand the weight of hinged furniture. For example, each fastener may hold a cabinet or shelf weighing 25 kilograms, and no problems should arise. The installation must be carried out in such a way that the partition fits tightly with the floor and adjacent structures. Both the small weight of the blocks themselves and the maximum sound insulation are important.

If aerated concrete blocks are planned to be placed between the living room, kitchen or other rooms with varying temperatures, then heat insulation should be taken care of. But at the same time it is important to strive to ensure that the thickness does not greatly increase and allows to save space. It is important to observe the conditions of fire safety, because in the worst case, aerated concrete can prevent the spread of fire for no more than a quarter of an hour.

Finally, the material must be confirmed by certificates of quality and environmental friendliness.

Experts highlight the impressive advantages of such structures. The material is easily processed, so you can give it the most convenient shape and size, using an ordinary hacksaw.Observing the rules of installation, you can get a neat partition with a perfectly flat surface and neat seams, the thickness of which ranges from 1 to 3 millimeters. All this is possible, as the special cement glue is used for laying. The porous structure leads to the fact that the small weight and small thickness are complemented by a fairly decent sound insulation and thermal insulation. In addition, the material is relatively inexpensive.

The disadvantages of aerated concrete blocks are also present. The design is not very stable and depends largely on the materials used. Aerated concrete absorbs water, which sometimes makes it difficult to carry out finishing work. It may well happen that the layer of the same plaster simply does not hold onto the surface. Finally, it is quite difficult to fix any fasteners on the gas block. Some of them simply refuse to hold, while others oxidize and rust.

Aerated concrete partitions are usually erected when external walls are already standing. If their length and width are too large, then the framework will have to be reinforced with reinforced concrete structures. At the joints of floors and partitions, a compensatory seam filled with assembly foam or mineral wool is used. Edge joints are processed in the same way.It is also recommended to use reinforcing elements to connect the partition with the wall. In this case, all adjustments are made with a regular hacksaw.

Choosing a brand

Which gas block will be chosen depends on the purpose for which it is acquired: whether furniture or other structures will be mounted on it, whether it will simply become a partition, and between which rooms it will be located. Most often, preference is given to brands D500 and D600. The first is a structural insulation, and the second - only structural. The block sizes are as follows: the length is 625 millimeters, and the width varies from 75 to 200 millimeters.

Such structures can withstand up to 150 kilograms. In the case when you do not plan to hang anything on the partitions, you can choose blocks of brands D350 and D400. The standard partition wall has a thickness of 100 mm to 150 mm. There are also non-standard figures 75 mm and 175 mm. If serious loads are planned (for example, sports equipment or very heavy furniture), then it would be good to increase the thickness to 200 millimeters.

Experts recommend that the brand of blocks was not lower than D400.This indicator is the minimum density that can withstand partitions, whose height reaches 3 meters. Ideally, take the D500 or D 600.

The latter brand, although it costs more, is able to withstand hanging objects without any problems.

Calculations

The calculation of the required indicators for the construction of aerated concrete partitions is quite simple. To calculate the amount of material, the total wall area is divided by the side surface area of one block. This figure is added 4 or 5, used for trimming openings and corners. It is important not to forget to translate all data into the same units. The area of the wall itself is determined by multiplying the length and height minus the area of the openings, that is, windows, doors, or arches. If the wall has a rather complex shape, then it is better to divide it into several simple shapes.

How to build?

The construction of the walls of aerated concrete in the house can be done both with their own hands, and with the participation of specialists. At the first stage, the necessary materials are harvested: blocks stacked on pallets, glue and tools (saw, corner, trowel and others). Usually blocks packed in special film are brought on pallets.The coating will not only prevent the effects of precipitation, but also prevent the blocks from moving during transport.

Sometimes the film remains only on top, and the open sides allow you to air building material. When unloading can not use steel cables that can damage its surface. It is better to use soft slings or a forklift. The pallets themselves will need to be put on a flat platform so that the blocks do not twist and flood. In addition, it is important to remember that the top film is removed at the last moment.

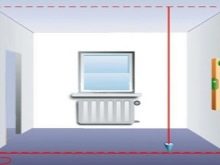

Next is the markup. The walls and floor of the room must first be cleaned from dirt. A cord covered with a dye is taken, it marks the place that the partition will take. Then there is the installation of temporary guides, usually wooden, they will have to mark the rows of masonry. In this case, the cord itself will determine the upper limit of the first row. After that, interior partitions begin to be mounted.

The blocks are laid out on a ruberoid, a rigid mineral plate, or another similar rolled material. It is possible to just miss the bitumen mastic.Such waterproofing will be able to dampen vibrations, and sound insulation will improve from it. If the floor is uneven, then on top you will have to create a cement layer, the height of which will vary from 20 to 30 millimeters. Focusing on the line of the cord, on the cement or glue with a layer from 2 to 5 millimeters, the first block is laid out, and then the rest is next to it.

Finishing element, cut from the whole block, cut off by measurement in place. It is greased with glue from two ends and is mounted in the remaining gap. In this case, before the opening should remain half a centimeter. After aligning the cord and the level and adjusting the position (tapping with a hand or a rubber hammer), you need to clean the top surface of dust, check for any differences and leave to dry for about 2 or 3 hours. Then the installation of the remaining rows begins.

When laying, it is important not to forget at each stage about the alignment and displacement of the end faces by half a block. If necessary, reinforcement with metal rods with glue is carried out every three rows or more often. Finishing work can be carried out only after 2 months. First, the seams are checked and, if necessary, treated with glue.Following the surface is rubbed, cleaned of dust and treated with an antiseptic. After this begins primer and plaster.

During the installation will have to follow a few important rules. First, the seam between the blocks in one row cannot be above the seam of another row. Between them there should be a gap of 20 centimeters. Secondly, between the ceiling and the upper surface of the partition should remain approximately 2 centimeters. This gap is filled with foam or soundproofing material. Its presence will protect the partition from cracking that may occur due to deflection of the ceiling. Thirdly, you can only use a special glue. If the choice is made in favor of a solution of sand and cement, then in addition it is necessary to seal rough seams. The masonry will become less even and neat, but it will still not be possible to save money.

Door openings

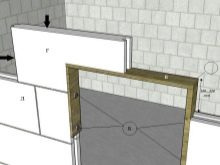

Aerated concrete partitions can not be carriers, so they do not have to be afraid of excessive loads. This means that there is no need to lay a high-grade lintel or reinforced concrete beams above the doorways.If the size of the arch fits into 0.8 meters, then fit blocks 60 centimeters long and 100 millimeters wide. They do not have jumpers.

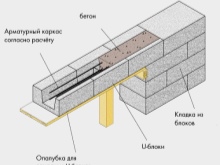

First, a temporary structure is mounted in the opening, where two blocks will be installed - “corners”, which will become the basis for the overlying elements. Their ends, smeared with glue, should be in the center. Then the remaining rows are laid. If the length of the openings exceeds 0.8 meters, you will have to use a variety of jumpers. The prefabricated structure also requires internal reinforcement and pouring with concrete.

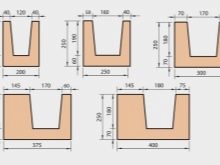

Often, a U-block is mounted above the doorway, having a standard length of 50 centimeters and a width corresponding to the dimensions of the wall elements. It is also laid reinforcement, all filled with special concrete or a mixture of sand and cement. The weight of the metal elements, as well as the composition of the fill, is determined depending on the size of the opening and the possible load.

First mounted supports under the opening. Then U-blocks are installed with glue applied on vertical seams. The thick side wall should be on the outside of the partition.The armature is mounted inside the cavity assembled from the modules, everything is filled with a special solution. If it is concrete, then it will have to be sealed with a bayonet.

At the last moment, the surface of the mortar is aligned to fit the top of the masonry.

Tips

Aerated concrete walls have a very mediocre ability to protect against noise, especially in the case when the block is 100 millimeters thick. To finish up the norm, one has to either use an extra layer of finish, or else sheathe the structure with mineral wool. Although the latter material is not a complete sound insulator, it will reduce the noise penetration by almost half. It will turn out to use special materials, but only those that possess the required vapor-permeable characteristics. In the case when you want to achieve maximum silence, experts advise to mount two thin partitions, the gap between which will be filled with material that absorbs noise

To learn how to make a partition of aerated concrete blocks, see the following video.