What are the dimensions of the gas block?

Everyone wants to pick up high-quality but low-cost materials for building a house In an effort to save, people do not always choose the right raw materials, which leads to unsustainable construction. Manufacturers of building materials offer a wide selection of materials for building construction. Today, aerated concrete is in great demand.

Material characteristics

Aerated concrete block is a stone of artificial rock. The gas-block is created from special cellular concrete.

Aerated concrete is a type of concrete porous rock. To create it, use cement sand, quartz sand and special blowing agents, such as aluminum paste or special suspensions.Some manufacturers mix the listed elements with gypsum, ash or lime.

The resulting mass is subjected to heat treatment in autoclaves at high temperature pressure. Due to the chemical reaction that takes place inside the autoclave, foaming of the cement slurry is obtained, followed by hardening. Inside the frozen cement block pores are formed. Some manufacturers of gas blocks in the production of voids occupy more than eighty percent. A high percentage of pores means that the material is lightweight and, therefore, less durable. In addition, the more pores, the worse the thermal conductivity of the material becomes.

In addition, developers prefer gas blocks for the construction of curtain walls and load-bearing walls, since these materials have special properties:

- high rate of physical and technical characteristics;

- improving the energy efficiency of the building.

Having decided to use an aerated concrete block in the building, it is necessary to find out about the main technical characteristics of this material. It is important to make this, because it is possible to avoid wrong choice and overpayment for low-quality material.

The main advantages of such a building material as a gas block, include:

- good sound insulation, if the thickness of the wall concrete is three hundred millimeters, the noise produced is less than 60 dB;

- low density, that is, lightness of a block, which is five times lighter than ordinary concrete, and two times lighter than a brick;

- ease of use, aerated concrete is easily cut with a hacksaw;

- at the same thickness of the gas block and brick, the thermal conductivity of the block is five times better;

- environmental friendliness of the material makes it possible to carry out construction work safely and without harm to health;

- construction speed increases several times, since the concrete block is large in size and replaces up to fifteen 1NF bricks;

- in the aerated concrete masonry there are no cold bridges;

- budget price;

- gas concrete material is fire resistant due to fire safety of cellular concrete

Despite the many advantages, the material has several drawbacks:

- moisture absorption rate is higher than that of similar building materials;

- low strength of the material.

What are the dimensions affect?

The dimensions of aerated concrete blocks have an impact on the entire building as a whole.The thickness of this material affects the strength, heat insulation and sound insulation of the wall being erected. The thicker the size of the gas block, the much quieter and warmer it will be in the building. Therefore, it is recommended to choose aerated concrete with a thickness of at least thirty centimeters for the structure of the bearing and exterior walls. As for the structure of partitions, here the thickness should not be more than ten or fifteen centimeters.

In addition, the height of the building gas block also affects the construction process.

- the greater the height, the less need to purchase concrete blocks. This will save money on building material.

- the higher and smoother the aerated concrete, the stronger the structure of the building. In addition, the evenness of the material eliminates the appearance of cracks.

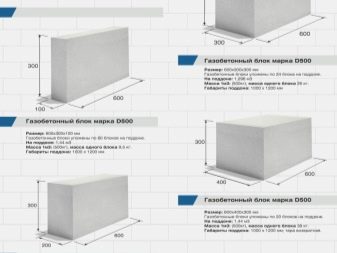

Standard parameters

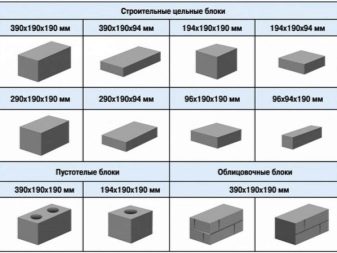

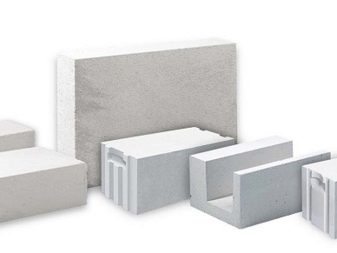

The dimensions of the concrete material to be used in construction depend on the purpose of the future construction. Gas-blocks come in various applications, but two types of blocks are in great demand in the building materials market: partition and wall. Dimensions of a single concrete block are regulated according to GOST standards.

Gostovsky standard indicates that the size should fit into the following parameters:

- thickness (width) - range from one hundred to five hundred millimeters;

- height - in scale from two hundred to three hundred millimeters;

- length up to six millimeters.

However, these figures vary depending on the type of aerated concrete. Each form of blocks has its own standard sizes. But the same for all remains that the weight of the material remains light, even despite the size and length, which for all types is six hundred and fifty millimeters.

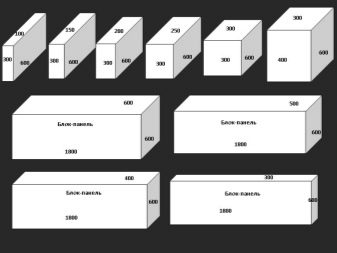

Gas block used in the construction of the outer wall:

- straight lines - width from two hundred to three hundred millimeters, height from two hundred fifty to three hundred millimeters;

- the tongue and groove made by the system and having gripping handles — the thickness is four hundred millimeters, the height is two hundred and fifty millimeters:

- straight lines, equipped with gripping handles - thickness is four hundred, height is twenty-five millimeters;

- simple with a groove-comb system - three or four hundred by two hundred and fifty millimeters.

Gas blocks for partitions:

- straight lines - one hundred fifty millimeters wide, two hundred fifty high;

- partitions - one hundred to two hundred and fifty millimeters.

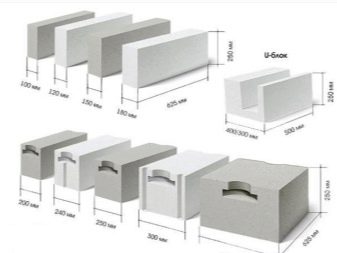

Aerated concrete blocks in the shape of the letter U differ in size. They are used in the construction of window and door openings. Their width is from two hundred to four hundred millimeters, height - two hundred fifty millimeters.

In addition to these types of products are common, whose thickness does not exceed seventy-five millimeters. They are necessary for the construction of interior partitions, as well as the construction of the bearing walls of the building. In addition, they play the role of additional warming.

How to choose?

Many people who do not know the intricacies of the construction business are faced with the problem of choosing an aerated concrete block. In order not to make the wrong choice, which can later lead to building instability, choosing the type of blocks, it is recommended to follow the following criteria.

When choosing a gas-concrete block, it is important to remember that this material is not universal. For different types of buildings it is important to choose the material that is suitable for the purpose of construction. For the construction of load-bearing walls and the construction of capital partitions, wall blocks are suitable; in the construction of an internal partition, a partition type of a gas-block is used. Understanding what makes them different is easy.The difference between the partition and wall block is the thickness. In the septum it does not exceed two hundred millimeters.

And also choosing, it is recommended to specify the density of the block. High density shows high material strength and high thermal conductivity. Consequently, construction materials with the highest density mark need to consider thermal insulation. A brand with an average density, D500, is very popular. It is suitable for all types of construction. But in the construction of partitions will be more rational use of the brand D500.

When choosing a dimensional block, the builder needs to know the size of the block and carry out the calculation. This is necessary in order to understand how many blocks will be needed to build all the walls. In addition, it is desirable to clarify with the seller about the presence of the groove and the ridge in the blocks. This is an optional requirement, but due to the presence of these elements, laying becomes easier, and glue consumption is much more economical. However, the price of this type of unit far exceeds the cost of the usual.

One more important criterion on which it is necessary to rely when choosing aerated concrete blocks is its brand.Most often, produced aerated concrete blocks of all brands are made equally using the same equipment and similar composition. If the cost of one brand in a store significantly exceeds the cost of another, then the buyer simply overpays for the brand and the fame of that brand. In addition, you should pay attention to the location of the plant, manufactured products. Often, the high price is due to the remoteness of the plant, and the store overpays for logistics.

When calculating the required amount of material, the builder must take into account that the alleged adhesive consumption, which, according to the manufacturers, they greatly underestimate. Most likely, during the construction work will require much more material. The exact amount of consumable is determined by the quality of the gas block and its dimensions.

In accordance with the standards of GOST, no more than five percent of chips and debris on a block material are allowed. However, this indicator is only suitable products of the first grade. The material of the second grade is characterized by a ten percent figure. Chipped aerated concrete is suitable for masonry exterior walls with subsequent lining.The choice of this type of block will save a quarter of the cost planned to spend on the material.

The final important criterion to help choose a block is the linking basis. From the type of the coupling base, the view of the gas block itself also changes. It is required to choose building materials with a deviation in all parameters for a dry screed. The thickness of the block should be no more than one and a half millimeters. Mortar glue also requires deflection. It should not be more than two millimeters, and on laying with the use of solutions - no more than five.

What is a gas block, about its types and dimensions, see the video below.