Criteria for selecting anchors for aerated concrete

It is known that aerated concrete is a fairly light building material and, moreover, porous. Ease and porosity are considered the main and most important advantages. But nevertheless, this structure has its own drawbacks - for example, in such a block the screw will not hold at all, it is impossible even to fasten a nail. Therefore, to resolve the issue with fasteners in aerated concrete, you need to hammer the anchor.

Special features

Anchor fasteners are two main parts.

- The expansion part, that is, the one that, after mounting, changes its own geometry, thus providing a strong fixation of the anchor directly into the thickness of the material with a porous structure. If we talk about chemical anchors, the part that is not in a solid state, but a liquid one, easily seeps into the pores, contributing to a sufficiently reliable fixation.

- The core is inside, that is, the part that is fixed in the spacer part itself.

The spacer has a rim and cuffs, due to which the mount can not fall into the drilled holes. The design of its length is different - from 40 mm to 300 mm. The diameter is usually no more than 30.

Species

Anchors that are used for aerated concrete, according to the method of attachment is divided into several separate types:

- chemical;

- mechanical.

Each of the varieties has its advantages and disadvantages, as well as methods of fasteners. It is worthwhile to separately dwell on the features of both types.

Chemical

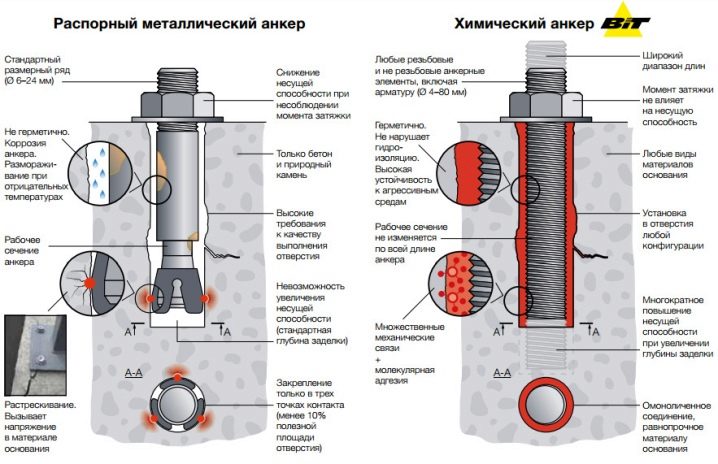

By the principle of fixation, each chemical element is based on the following, in such a porous material as foam concrete or aerated concrete penetrates the binding type of substance, then this substance hardens and forms a solid connection when solidified. This system is used infrequently, and yet without it simply can not do when the anchors need to withstand a sufficiently large load. One capsule contains polymers with organic resins.

Consider how to conduct a competent installation.

- To begin with, a hole is drilled in the porous aerated concrete. Engage in this work is better than an ordinary drill.

- The vials are inserted into pre-drilled holes, which contain specialized chemical compounds.

- It is necessary to break the ampoules, and then insert a metal rod into the same hole.

- It now remains to wait for the moment of solidification of the connecting element. Usually, it is allocated a few hours, and sometimes a day.

This system has its own advantages:

- able to withstand a tremendous burden;

- damp and moisture do not penetrate under the anchor;

- there will be no cold bridges in the place of attachment;

- the connection is sealed.

If you list the shortcomings of this design, then you can include here the impossible implementation of the dismantling of anchors. It is also worth noting that similar products are quite expensive compared to other types of fasteners.

Massa-Henke and HILTI are the most famous manufacturers of chemical fasteners. The products of world manufacturers have a correspondingly higher price, but here you can remain completely confident that the quality of the installation system will remain at the same level.

Epoxy

Chemical anchor bolts created on the basis of epoxy resin are used during installation on a solid foundation or foundation, for example, on concrete.These bolts with a similar effect can hold the suspension structures that are attached to concrete surfaces and not only, the bolts also perfectly hold the suspension structure attached to the reinforced concrete beam. Often used these products for fastening a variety of equipment.

Epoxy type anchor bolts has its own advantages.

- It is possible to carry out installation of these elements even in water or in the presence of moisture.

- Installation using these bolts can be done indoors or from the inside.

- In the mounting hole, the local type of stress is minimized, so there are no cracks in the anchor joint zone.

- The resin does not contain styrene.

- Products are used for fastening smooth studs, and for threaded. This property is constantly used when mounting the rebar.

The mounting of anchors made on the "epoxy", will also be affected by the air, or rather, its temperature. The first setting occurs within 10 minutes, and then the time can be delayed up to 180 minutes. Full hardening occurs in 10-48 hours. Only after 24 hours the structures can be loaded.

Polyester

This type is widely used for fixing various parts of the suspended facade on the aerated concrete base, and is also used to mount a translucent facade, communication network and engineering. In the form of a rod only threaded studs are used; they can be metal or plastic.

To get a more durable connection, it is recommended to use a special tapered drill bit when drilling a hole. Polyester resins do not contain styrene at all; accordingly, such resins can be used with confidence for fixing hanging parts located in a building.

Mechanical

The strut of fasteners, which firmly holds the anchor body inside the porous building material, helps to achieve reliable fixation when installing mechanical anchors. Usually consists of such fasteners from a special tube, which is inserted into the holes. It changes its own geometric shape as a result of screwing in or at the time of clogging of the inner rod.

Among the advantages of this fastener:

- anchors are installed in the aeration of aerated concrete is quite simple;

- a lot of time to mount the system does not go away;

- all load will be distributed evenly in the future;

- after mounting the anchor to the installation of mounted elements, you can proceed immediately;

- the fastening system can always be dismantled when the need arises.

It is easy to perform and install rods:

- to begin with, drill a hole of the required diameter;

- then insert the tube inside the finished hole;

- upon completion of the work, you need to independently install the spacer type of the rod, that is, the one that at any time can be both screwed and hammered.

Most major manufacturers, for example, HPD, HILTI or Fisher GB, claim to supply products with guaranteed quality. Typically, this type of anchor is made of fairly durable materials - stainless steel. Still, these products may be subjected to oxidation, and this is perhaps the most fundamental drawback.

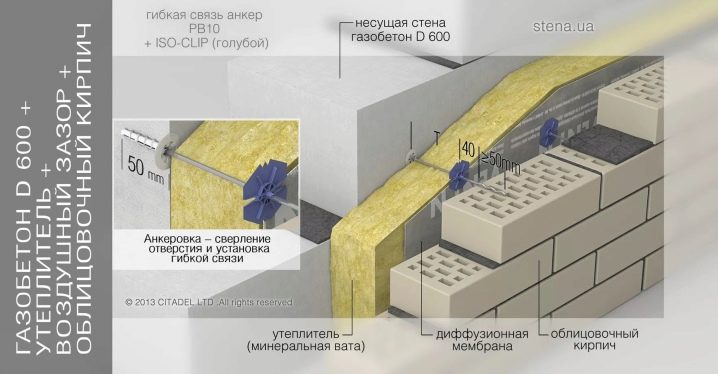

If during the construction of houses that are built from a gas block, it is necessary to use an anchor, that is, flexible connections. Domestic manufacturing companies are engaged in the manufacture of these fasteners.

Anchors are made of basalt plastic core. Sand coating on the anchor allows you to achieve the best adhesion to cement. In addition, the flexible connection created from steel material (stainless steel) is produced by the German company Bever.

A common type of fasteners, which are used when working with aerated concrete, also includes a butterfly anchor. The fixation of this product is carried out with the help of segments-petals, they are firmly fixed on the aerated concrete porous building material. This type of product is supplied by the manufacturer MUPRO.

findings

Despite the existing opinion, according to which it is impossible to fix anything on porous concrete, the use of anchors can provide a truly reliable mount. At the same time, chemical fastener systems can withstand rather large loads. But you should buy products from a trusted manufacturer, who gives a guarantee on all their products.

Next, see the overview of the anchor for aerated concrete Fischer FPX - I.