How can you cut aerated concrete?

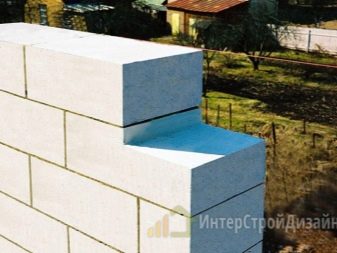

Blocks of aerated concrete can be perfectly handled by almost any tools. They can be cut with a power tool or processed manually, which allows you to make parts of any geometry with inclined, oblique, figured edges.

Overview of all tools

To work with aerated concrete material are used:

- special manual hacksaw;

- chain power saw;

- saber saw;

- saw "Alligator";

- machines for cutting aerated concrete;

- devices such as milling cutters, discs, etc. can also be used.

Further in the article we will consider the above-mentioned tools, their pros and cons, and also draw conclusions about how and with the help of which it is preferable to process aerated concrete.

What to consider when choosing?

With regard to hand tools, the best option for processing aerated concrete will be a model with teeth, equipped with a hard soldering. Its high cost may well be justified by the high durability of the tool. This will not affect the cutting time (it will be long enough), but the safety of the material and cutting accuracy will be higher. It is better to cut large-sized blocks with a two-handed tool, but its weight is much more - you need a partner.

It is preferable to use the products of a well-known company.and not to purchase handicraft tools with questionable workmanship. Perfectly established itself as the manufacturer of the tool “Utong”. A good economist is the products of the brand "Delta". A manual hacksaw makes neat cuts, forms window or door openings. The disadvantage of this tool - you have to cut at low speed.

When buying a saw, you need to pay special attention to its characteristics. The power of household models is relatively low, overheating can happen in less than half an hour and you have to turn them off periodically. They cost about two or three thousand rubles, while the cost of a professional saw can exceed this amount by 10 times.

But the tool of this class is designed for a daily schedule of work, providing for continuous operation. In this mode, the saw can work more than 5 hours in a row. Power they are from 500 to 1500 watts.

By type of drive tool is divided into:

- corded, more powerful and productive, but not so mobile (you have to use an extension cord);

- battery (electric hacksaw has less weight, it is treated with aerated concrete at construction sites).

Additionally, it can be noted that there are functions such as adjusting speeds, changing the web without using keys. Not bad, if there is an anti-vibration protection in the saber saw.

When purchasing consumables for elektroshohovok need to pay attention to the type of cutting tooth. The size of the teeth and the spacing between them indicate where they should be applied. For example, a snap with a large chisel is used for high-speed cutting, with a small one for figured cuts. The shortest tooth spacing gives ideal cutting planes, and with large wiring, the cutting time is shortened, but this is inevitably accompanied by a loss of quality.

How to cut?

Hacksaw

In the case when the projects of constructed houses or other structures do not imply that they will have complex geometric shapes, the acquisition of expensive power tools is meaningless. It is quite enough to use a regular hacksaw. It is used to process a small amount of material. The quality and speed of cutting is influenced by technical, strength, density factors of the material, as well as the level of temperature and humidity of the air environment.

Attention! To cut dry blocks better in warm conditions. If the gas block absorbs moisture from the ambient air or gets wet for other reasons, the saw blade can become bogged down when sawing.

Consider the immediate process of cutting.

- To get a flat line you will need a pencil and a square.On the aerated concrete markup is applied on each of the four faces. Then cuts are made to a depth of 1-4 cm along two long and one short edges. Hand tools should have a canvas of sufficient length, reach the end of the cut and clean the sawdust from the passage.

- The canvas is directed without excessive pressure, so that there is no escape from the marking line. The optimum cutting angle is 45 °. It is necessary to ensure that the part to be cut does not fall, the cut code will be completed. Also in order to avoid chipping you need a reliable stand, a corner.

With pre-cut cuts, the tool will remain on the cutting line, which will make cutting easier and more efficient. It takes an average of 5-7 minutes to saw a single concrete block of standard standard 400x250 mm with a density of D500 using a hand saw. With the construction of large buildings, the time spent on the preparation of the material will be significant.

Reciprocating Saw

Reciprocating saws are power tools that look like powerful electric jigsaws. Structurally, the reciprocating saw consists of the tool itself and the casing. With the help of a saber saw you can cut both in a straight line and carry out the so-called saber cut.The saw cuts the aerated concrete block using flat cutting blades slightly resembling cavalry sabers. The canvas is moving rotationally, progressively, the required speed limit is set using the electronic unit. Saw models are distinguished by engine power and length of working blades. The amplitude of the oscillation of the blade of saber saw varies from 2 to 5 cm, the frequency of movement can reach up to 3000 strokes per minute. Worn cloth easily changes to a new one.

All modifications are equipped with heat removal systems. The saber saw is distinguished by excellent cutting accuracy, high efficiency, it can change the level of cutting depth, it is possible to fit the blocks to the required dimensions. With its help it is possible to partially break down aerated concrete for wiring. The disadvantage is an expensive tool. If you plan to work with aerated concrete, you will need specialized canvases.

Chained

Chain electric saws are classified as universal products, as such a tool is in almost every household. The saw consists of a cutting chain, a saw tire, a tensioning mechanism, a lubrication system that blocks the engine guard.For optimal saw performance, chain tension adjustment is required with a special tire screw.

Advantages of operation: professionals are mostly considered the best option to use chainsaws when sawing gas-blocks of the U-configuration. When sawing from the butt you can get the perfect shape of the horizontal cut. The chain saw provides high cutting speed. It is also necessary to note the optimal balancing of the mass: a chain saw is convenient to use when cutting from different angles and, if necessary, keep it above the head.

A significant drawback of electric saws is the relatively rapid blunting of the chain when cutting aerated concrete, since the direct purpose of the saw is to cut wood. For this reason, when buying a saw, it is recommended to purchase chains with a fine soldering. Of course, such a chain is much more expensive than ordinary, but in any case it will be necessary to sharpen it in any case.

When sawing two or three blocks in a row, the chain heats up, the metal expands, which leads to its stretching. To eliminate this problem, it is necessary to remove one link, then it will correspond to its previous parameters.For this reason, there are strong recommendations on the mode of operation - the tool should rest. If you work in heavy environments (for example, cutting aerated concrete blocks instead of cutting wood trunks), an asterisk saws its teeth.

It should be noted that all models of electric motors at chainsaws do not tolerate dust, one way or another, formed in the process of sawing aerated concrete. As a result, the saw is broken and is unlikely to be able to recover it (unless it is possible to change the engine).

Power saw type "Alligator"

Uninformed people often perceive this option as a type of saber type, but they are different. In the operation of the "Alligator" are given in the sliding plane of the paintings. They move in the same way as the movements of crocodile jaws. They do not go back and forth, as in saber counterparts, cutting occurs at the expense of the saw bar, which is installed fixed.

Since the Alligator type saw has high power, it is optimal for cutting aerated concrete. When oncoming traffic, the block is especially stable. A braking system for cutting planes and a switch lock system are provided.Dustproof also provides higher tool life and reliability.

The saw is convenient to use, it is easy to replace consumables. The set includes a hex key and blades for cutting aerated concrete. As for the drawbacks, this is a traditional high cost: it makes sense to buy such a saw only with its constant use.

"Alligator" is the best, but too expensive tool. Its acquisition can be recommended for professional builders who build a large number of aerated concrete buildings. A private developer doing their own hands can be satisfied with a less expensive solution.

Machine

The highest possible accuracy and the smoothest surface when cutting an aerated concrete block can be provided with a machine. More precisely, it is used for cutting bulk masses having different parameters. It can be installed anywhere and does not take up much space. Structurally, it usually consists of a frame, which is equipped with a screw, two electric drives and cutting elements (the latter can be band saws or strings), a trigger screw, a starting frame mechanism, a winch for vertical movements of the frame, and a trolley.

The advantages in the use of this type of equipment consist in its high performance, fast payback, and economy in resources. There are certain disadvantages: the equipment is expensive, it is not mobile, it is problematic to transport it. But it is difficult to find more convenient equipment for the manufacture of aerated concrete blocks.

Safety

Safety precautions when conducting cutting gas blocks slightly differ from the rules of TB in other similar actions. In general terms, it is necessary to note the obligatory use of working clothes, special attention should be paid to shoes with metallic toes, gloves and eye and face protection (mask, goggles).

In the next video you will find an effective way to cut aerated concrete.