How to make aerated concrete?

Aerated concrete - one of the types of cellular concrete, which has high technical characteristics, while its price is very budget. This building material can be easily made independently with the help of special equipment.

Manufacturing

Independent production of aerated concrete can be a help not only for low-rise individual construction, but also provides an opportunity to start your own business.

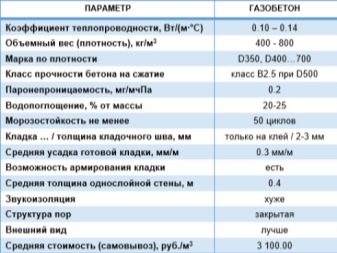

These building blocks are very popular because they have the following properties:

- low density, which is almost five times less than that of classical concrete and three times less than that of brick;

- water absorption is about 20%;

- thermal conductivity is 0.1 W / m3;

- maintains more than 75 defrosting / freezing cycles (which is 2 times higher than the brick index);

- high compressive strength allows to build two- and three-story houses;

- excellent sound insulation due to the porous structure;

- high fire resistance class;

- it is easy to work with material - to cut, hammer nails;

- safe for both humans and the environment, as there are no harmful components in the composition;

- it is possible to create a monolithic cast structure based on aerated concrete blocks.

Manufacturing building gazoblokov forces even a novice. The whole benefit of independent work lies in high performance, simple manufacturing scheme, affordable and inexpensive materials for mortar, with the result is a building material of very decent quality with excellent technical characteristics.

Equipment and technology

There are several options for the type of line for the production of aerated concrete blocks. depending on the volume and conditions of placement.

- Stationary lines. Placed to produce from 10-50 m3 blocks per day. For work of such equipment 1-2 workers are necessary.

- Lines as a conveyor. They produce about 150 m3 per day, which ensures regular large volumes of products.

- Mobile installations. Used for self-manufacturing blocks of aerated concrete anywhere, including directly on the construction site.

- Mini lines. This is an automated complex for the production of up to 15 m3 per day of aerated concrete blocks. The installation itself takes about 150 m2. The line requires 3 people.

- Mini-factory. This line is capable of producing gas blocks up to 25m3. It also requires the work of 3 workers.

Stationary equipment is considered to be the most profitable and reliable, since all the hard stages are automated here and manual labor is not always needed. In these lines, a mobile mixer, a special complex for preparing and storing the solution, heating water and a conveyor for feeding components to the dispenser are used. Stationary lines are productive (up to 60 m3 finished blocks per day), but they require large areas for installation (about 500 m2) and are very expensive.

Producer prices of these lines in Russia start from 900 thousand.rubles, the equipment of foreign production will cost even more.

Conveyor lines implement a fundamentally different production model - the dispenser and aerated concrete mixer do not move, only forms move. The process is completely autonomous, but due to high production rates it will be difficult to maintain such a process on its own - 4-6 people will be required. Located on an area of 600 m2, its cost starts from 3,000,000 rubles. This option is suitable for those who plan to produce blocks for the purpose of their further sale.

Mobile lines are the best option for independent production of blocks for individual construction. The main advantage is the compactness of the equipment, the machine takes up only 2x2 m2. It can be placed in any convenient place: on the construction site, in the garage and even at home. The line consists of a compact mixer, compressor and connecting hose, which allows you to fill several forms at once. The equipment is serviced by one person. Prices for mobile installations do not exceed 60 thousand rubles and consume relatively little electricity.

Mini-lines can be stationary and conveyor type. Such plants are produced by the Russian companies Inntechgroup, Kirovstroyindustriya and Altaystroymash. Components of different manufacturers may differ slightly, but all models have the main components (mixer, machine for cutting blocks and mold). They can occupy an area of 10 to 150 m2. It will also be necessary to organize a separate place for drying gas blocks. Mini-factories are often a launching pad for those who decide to manufacture and sell blocks of aerated concrete. Most domestic manufacturers of this equipment do not autoclave it. However, in the first stages you can do without it. It can significantly reduce the drying time of the blocks and increase the daily production of the plant.

How to make at home?

Doing your own hands to produce aerated concrete blocks is very beneficial not only for individual needs, but also for the sale and organization of small businesses. Raw materials and tools for the manufacture of this building material can be purchased from the hands, in specialized stores or directly from the manufacturer.

Some craftsmen make their own forms for the blocks, which saves on their purchase.

You can make aerated concrete in two ways: using an autoclave and without it. The first option involves the purchase of special equipment, in which there is a "baking" of aerated concrete blocks under high pressure and temperature. Due to this effect, tiny gas bubbles appear in the pores of the concrete, which improve the technical characteristics of the material obtained. Such blocks have greater strength and durability. However, this method is not suitable for home use, as the autoclave is not cheap, and also because it will be difficult to organize the technology on its own.

Therefore, for the manufacture of blocks with their own hands is suitable the second method, without the use of autoclave equipment. In this embodiment, the drying of aerated concrete takes place in natural conditions. Such blocks are somewhat inferior in terms of strength and some other characteristics to autoclave blocks, but they are quite suitable for individual construction.

The following tools will be required for self-installation of the aerated concrete plant:

- forms for concrete mix;

- concrete mixer for the preparation of the solution;

- shovel;

- metal string.

You can also purchase special equipment that doses and prepares the mixture on its own - this will significantly speed up the material production process.

The technology of self-production of aerated concrete blocks has three mandatory steps.

- Dosing and mixing of dry ingredients in the required proportion. At this step, it is important to accurately follow the selected dosage, since by changing the ratio of components you can get a concrete that is different in technical characteristics.

- Add water and stir the solution until smooth. At this stage, the pores formed in the mixture should be evenly distributed, so it is advisable to use a concrete mixer.

- Filling forms. Special compartments are filled with a solution only by half, since in the first few hours the active formation of gas bubbles continues, and the mixture increases in volume.

Then, after 5-6 hours after filling in the forms, the blocks are cut off the excess mixture using a metal string. Then the blocks remain in the forms for another 12 hours.You can leave them on the construction site or indoors. After pre-solidification, the blocks can be removed from the containers and left to dry for several days and only then be stored for storage.

The final strength of aerated concrete is gaining in 27-28 days after production.

Forms and components

An important step in the independent production of concrete blocks is the choice of suitable forms.

Containers for pouring aerated concrete can be as follows.

- Collapsible. You can remove the board at any stage of block freezing. These structures require additional physical strength.

- Kolpachnye. Removed completely with the help of mechanized systems.

Material manufacturing forms can be different: metal, plastic and wood. Metal containers are most in demand, as they are distinguished by their durability and strength. They are produced in two types, depending on the volume (0.43 and 0.72 m3). Whichever recipe is chosen for the manufacture of blocks, the raw material requires the same.

Components for the production of aerated concrete are:

- water (consumption of 250-300 liters per m3);

- cement (consumption 260-320 kg per m3);

- sand (consumption of 250-350 kg per m3);

- modifier (2-3 kg per m3).

Some requirements are imposed on raw materials for the production of blocks. Water should be of medium hardness with minimal salinity. Cement for the mixture must comply with GOST. Portland cement M400 and M500 should be preferred. Not only river or sea sand, but also ash, spent slag, dolomite flour, limestone can act as a filler. If sand is used, it should not contain organic inclusions, a large amount of silt and clay. The smaller the fraction of the filler, the smoother the surface of the blocks. As a modifier, in order to accelerate the maturation of aerated concrete can be: gypsum alabaster, calcium chloride and water glass.

Do-it-yourself production of concrete blocks is a long, but not very complicated process that will significantly reduce the cost of building materials. If the proportions and manufacturing techniques are observed, the aerated concrete blocks are almost as good as the factory ones and can be safely used for low-rise construction.

How the aerated concrete is produced on the mini-line, see the following video.